Title: De Re Metallica, Translated from the First Latin Edition of 1556

Author: Georg Agricola

Translator: Herbert Hoover

Lou Henry Hoover

Release date: November 14, 2011 [eBook #38015]

Most recently updated: January 8, 2021

Language: English

Credits: Produced by Malcolm Farmer, Stephen H. Sentoff and the

Online Distributed Proofreading Team at https://www.pgdp.net

with

Biographical Introduction, Annotations and Appendices upon

the Development of Mining Methods, Metallurgical

Processes, Geology, Mineralogy & Mining Law

from the earliest times to the 16th Century

A. B. Stanford University, Member American Institute of Mining Engineers,

Mining and Metallurgical Society of America, Société des Ingéniéurs

Civils de France, American Institute of Civil Engineers,

Fellow Royal Geographical Society, etc., etc.

A. B. Stanford University, Member American Association for the

Advancement of Science, The National Geographical Society,

Royal Scottish Geographical Society, etc., etc.

1950

Dover Publications, Inc.

NEW YORK

The inspiration of whose teaching is no less great than his contribution to science.

This New 1950 Edition of DE RE METALLICA is a complete and unchanged reprint of the translation published by The Mining Magazine, London, in 1912. It has been made available through the kind permission of Honorable Herbert C. Hoover and Mr. Edgar Rickard, Author and Publisher, respectively, of the original volume.

PRINTED IN THE UNITED STATES OF AMERICA

here are three objectives in translation of works of this character: to give a faithful, literal translation of the author's statements; to give these in a manner which will interest the reader; and to preserve, so far as is possible, the style of the original text. The task has been doubly difficult in this work because, in using Latin, the author availed himself of a medium which had ceased to expand a thousand years before his subject had in many particulars come into being; in consequence he was in difficulties with a large number of ideas for which there were no corresponding words in the vocabulary at his command, and instead of adopting into the text his native German terms, he coined several hundred Latin expressions to answer his needs. It is upon this rock that most former attempts at translation have been wrecked. Except for a very small number, we believe we have been able to discover the intended meaning of such expressions from a study of the context, assisted by a very incomplete glossary prepared by the author himself, and by an exhaustive investigation into the literature of these subjects during the sixteenth and seventeenth centuries. That discovery in this particular has been only gradual and obtained after much labour, may be indicated by the fact that the entire text has been re-typewritten three times since the original, and some parts more often; and further, that the printer's proof has been thrice revised. We have found some English equivalent, more or less satisfactory, for practically all such terms, except those of weights, the varieties of veins, and a few minerals. In the matter of weights we have introduced the original Latin, because it is impossible to give true equivalents and avoid the fractions of reduction; and further, as explained in the Appendix on Weights it is impossible to say in many cases what scale the Author had in mind. The English nomenclature to be adopted has given great difficulty, for various reasons; among them, that many methods and processes described have never been practised in English-speaking mining communities, and so had no representatives in our vocabulary, and we considered the introduction of German terms undesirable; other methods and processes have become obsolete and their descriptive terms with them, yet we wished to avoid the introduction of obsolete or unusual English; but of the greatest importance of all has been the necessity to avoid rigorously such modern technical terms as would imply a greater scientific understanding than the period possessed.

Agricola's Latin, while mostly free from mediæval corruption, is somewhat tainted with German construction. Moreover some portions have not [Pg ii]the continuous flow of sustained thought which others display, but the fact that the writing of the work extended over a period of twenty years, sufficiently explains the considerable variation in style. The technical descriptions in the later books often take the form of House-that-Jack-built sentences which have had to be at least partially broken up and the subject occasionally re-introduced. Ambiguities were also sometimes found which it was necessary to carry on into the translation. Despite these criticisms we must, however, emphasize that Agricola was infinitely clearer in his style than his contemporaries upon such subjects, or for that matter than his successors in almost any language for a couple of centuries. All of the illustrations and display letters of the original have been reproduced and the type as closely approximates to the original as the printers have been able to find in a modern font.

There are no footnotes in the original text, and Mr. Hoover is responsible for them all. He has attempted in them to give not only such comment as would tend to clarify the text, but also such information as we have been able to discover with regard to the previous history of the subjects mentioned. We have confined the historical notes to the time prior to Agricola, because to have carried them down to date in the briefest manner would have demanded very much more space than could be allowed. In the examination of such technical and historical material one is appalled at the flood of mis-information with regard to ancient arts and sciences which has been let loose upon the world by the hands of non-technical translators and commentators. At an early stage we considered that we must justify any divergence of view from such authorities, but to limit the already alarming volume of this work, we later felt compelled to eliminate most of such discussion. When the half-dozen most important of the ancient works bearing upon science have been translated by those of some scientific experience, such questions will, no doubt, be properly settled.

We need make no apologies for De Re Metallica. During 180 years it was not superseded as the text-book and guide to miners and metallurgists, for until Schlüter's great work on metallurgy in 1738 it had no equal. That it passed through some ten editions in three languages at a period when the printing of such a volume was no ordinary undertaking, is in itself sufficient evidence of the importance in which it was held, and is a record that no other volume upon the same subjects has equalled since. A large proportion of the technical data given by Agricola was either entirely new, or had not been given previously with sufficient detail and explanation to have enabled a worker in these arts himself to perform the operations without further guidance. Practically the whole of it must have been given from personal experience and observation, for the scant library at his service can be appreciated from his own Preface. Considering the part which the metallic arts have played in human history, the paucity of their literature down to Agricola's time is amazing. No doubt the arts were jealously guarded by their practitioners as a sort of stock-in-trade, and it is also probable that those who had knowledge were not usually of a literary turn of mind; and, [Pg iii]on the other hand, the small army of writers prior to his time were not much interested in the description of industrial pursuits. Moreover, in those thousands of years prior to printing, the tedious and expensive transcription of manuscripts by hand was mostly applied to matters of more general interest, and therefore many writings may have been lost in consequence. In fact, such was the fate of the works of Theophrastus and Strato on these subjects.

We have prepared a short sketch of Agricola's life and times, not only to give some indication of his learning and character, but also of his considerable position in the community in which he lived. As no appreciation of Agricola's stature among the founders of science can be gained without consideration of the advance which his works display over those of his predecessors, we therefore devote some attention to the state of knowledge of these subjects at the time by giving in the Appendix a short review of the literature then extant and a summary of Agricola's other writings. To serve the bibliophile we present such data as we have been able to collect it with regard to the various editions of his works. The full titles of the works quoted in the footnotes under simply authors' names will be found in this Appendix.

We feel that it is scarcely doing Agricola justice to publish De Re Metallica only. While it is of the most general interest of all of his works, yet, from the point of view of pure science, De Natura Fossilium and De Ortu et Causis are works which deserve an equally important place. It is unfortunate that Agricola's own countrymen have not given to the world competent translations into German, as his work has too often been judged by the German translations, the infidelity of which appears in nearly every paragraph.

We do not present De Re Metallica as a work of "practical" value. The methods and processes have long since been superseded; yet surely such a milestone on the road of development of one of the two most basic of human industrial activities is more worthy of preservation than the thousands of volumes devoted to records of human destruction. To those interested in the history of their own profession we need make no apologies, except for the long delay in publication. For this we put forward the necessity of active endeavour in many directions; as this book could be but a labour of love, it has had to find the moments for its execution in night hours, weekends, and holidays, in all extending over a period of about five years. If the work serves to strengthen the traditions of one of the most important and least recognized of the world's professions we shall be amply repaid.

It is our pleasure to acknowledge our obligations to Professor H. R. Fairclough, of Stanford University, for perusal of and suggestions upon the first chapter; and to those whom we have engaged from time to time for one service or another, chiefly bibliographical work and collateral translation. We are also sensibly obligated to the printers, Messrs. Frost & Sons, for their patience and interest, and for their willingness to bend some of the canons of modern printing, to meet the demands of the 16th Century.

July 1, 1912.

The Red House,

Hornton Street, London.

eorgius Agricola was born at Glauchau, in Saxony, on March 24th, 1494, and therefore entered the world when it was still upon the threshold of the Renaissance; Gutenberg's first book had been printed but forty years before; the Humanists had but begun that stimulating criticism which awoke the Reformation; Erasmus, of Rotterdam, who was subsequently to become Agricola's friend and patron, was just completing his student days. The Reformation itself was yet to come, but it was not long delayed, for Luther was born the year before Agricola, and through him Agricola's homeland became the cradle of the great movement; nor did Agricola escape being drawn into the conflict. Italy, already awake with the new classical revival, was still a busy workshop of antiquarian research, translation, study, and publication, and through her the Greek and Latin Classics were only now available for wide distribution. Students from the rest of Europe, among them at a later time Agricola himself, flocked to the Italian Universities, and on their return infected their native cities with the newly-awakened learning. At Agricola's birth Columbus had just returned from his great discovery, and it was only three years later that Vasco Da Gama rounded Cape Good Hope. Thus these two foremost explorers had only initiated that greatest period of geographical expansion in the world's history. A few dates will recall how far this exploration extended during Agricola's lifetime. Balboa first saw the Pacific in 1513; Cortes entered the City of Mexico in 1520; Magellan entered the Pacific in the same year; Pizarro penetrated into Peru in 1528; De Soto landed in Florida in 1539, and Potosi was discovered in 1546. Omitting the sporadic settlement on the St. Lawrence by Cartier in 1541, the settlement of North America did not begin for a quarter of a century after Agricola's death. Thus the revival of learning, with its train of Humanism, the Reformation, its stimulation of exploration and the re-awakening of the arts and sciences, was still in its infancy with Agricola.

We know practically nothing of Agricola's antecedents or his youth. His real name was Georg Bauer ("peasant"), and it was probably Latinized by his teachers, as was the custom of the time. His own brother, in receipts [Pg vi]preserved in the archives of the Zwickau Town Council, calls himself "Bauer," and in them refers to his brother "Agricola." He entered the University of Leipsic at the age of twenty, and after about three and one-half years' attendance there gained the degree of Baccalaureus Artium. In 1518 he became Vice-Principal of the Municipal School at Zwickau, where he taught Greek and Latin. In 1520 he became Principal, and among his assistants was Johannes Förster, better known as Luther's collaborator in the translation of the Bible. During this time our author prepared and published a small Latin Grammar[2]. In 1522 he removed to Leipsic to become a lecturer in the University under his friend, Petrus Mosellanus, at whose death in 1524 he went to Italy for the further study of Philosophy, Medicine, and the Natural Sciences. Here he remained for nearly three years, from 1524 to 1526. He visited the Universities of Bologna, Venice, and probably Padua, and at these institutions received his first inspiration to work in the sciences, for in a letter[3] from Leonardus Casibrotius to Erasmus we learn that he was engaged upon a revision of Galen. It was about this time that he made the acquaintance of Erasmus, who had settled at Basel as Editor for Froben's press.

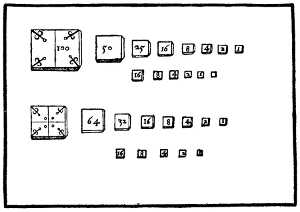

In 1526 Agricola returned to Zwickau, and in 1527 he was chosen town physician at Joachimsthal. This little city in Bohemia is located on the eastern slope of the Erzgebirge, in the midst of the then most prolific metal-mining district of Central Europe. Thence to Freiberg is but fifty miles, and the same radius from that city would include most of the mining towns so frequently mentioned in De Re Metallica—Schneeberg, Geyer, Annaberg and Altenberg—and not far away were Marienberg, Gottesgab, and Platten. Joachimsthal was a booming mining camp, founded but eleven years before Agricola's arrival, and already having several thousand inhabitants. According to Agricola's own statement[4], he spent all the time not required for his medical duties in visiting the mines and smelters, in reading up in the Greek and Latin authors all references to mining, and in association with the most learned among the mining folk. Among these was one Lorenz Berman, whom Agricola afterward set up as the "learned miner" in his dialogue Bermannus. This book was first published by Froben at Basel in 1530, and was a sort of catechism on mineralogy, mining terms, and mining lore. The book was apparently first submitted to the great Erasmus, and the publication arranged by him, a warm letter of approval by him appearing at the beginning of the book[5]. In 1533 he published De Mensuris et Ponderibus, through Froben, this being a discussion of Roman and Greek weights and measures. At about this time he began De Re Metallica—not to be published for twenty-five years.

Agricola did not confine his interest entirely to medicine and mining, for during this period he composed a pamphlet upon the Turks, urging their extermination by the European powers. This work was no doubt inspired by the Turkish siege of Vienna in 1529. It appeared first in German in 1531, and in Latin—in which it was originally written—in 1538, and passed through many subsequent editions.

At this time, too, he became interested in the God's Gift mine at Abertham, which was discovered in 1530. Writing in 1545, he says[6]: "We, as a shareholder, through the goodness of God, have enjoyed the proceeds of this God's Gift since the very time when the mine began first to bestow such riches."

Agricola seems to have resigned his position at Joachimsthal in about 1530, and to have devoted the next two or three years to travel and study among the mines. About 1533 he became city physician of Chemnitz, in Saxony, and here he resided until his death in 1555. There is but little record of his activities during the first eight or nine years of his residence in this city. He must have been engaged upon the study of his subjects and the preparation of his books, for they came on with great rapidity soon after. He was frequently consulted on matters of mining engineering, as, for instance, we learn, from a letter written by a certain Johannes Hordeborch[7], that Duke Henry of Brunswick applied to him with regard to the method for working mines in the Upper Harz.

In 1543 he married Anna, widow of Matthias Meyner, a petty tithe official; there is some reason to believe from a letter published by Schmid,[8] that Anna was his second wife, and that he was married the first time at Joachimsthal. He seems to have had several children, for he commends his young children to the care of the Town Council during his absence at the war in 1547. In addition to these, we know that a son, Theodor, was born in 1550; a daughter, Anna, in 1552; another daughter, Irene, was buried at Chemnitz in 1555; and in 1580 his widow and three children—Anna, Valerius, and Lucretia—were still living.

In 1544 began the publication of the series of books to which Agricola owes his position. The first volume comprised five works and was finally issued in 1546; it was subsequently considerably revised, and re-issued in 1558. These works were: De Ortu et Causis Subterraneorum, in five "books," the first work on physical geology; De Natura Eorum quae Effluunt ex Terra, in four "books," on subterranean waters and gases; De Natura Fossilium, in ten "books," the first systematic mineralogy; De Veteribus et Novis Metallis, in two "books," devoted largely to the history of metals and topographical mineralogy; a new edition of Bermannus was included; and finally Rerum Metallicarum Interpretatio, a glossary of Latin and German mineralogical and metallurgical terms. Another work, De Animantibus Subterraneis, usually published with De Re Metallica, is dated 1548 in the preface. It [Pg viii]is devoted to animals which live underground, at least part of the time, but is not a very effective basis of either geologic or zoologic classification. Despite many public activities, Agricola apparently completed De Re Metallica in 1550, but did not send it to the press until 1553; nor did it appear until a year after his death in 1555. But we give further details on the preparation of this work on p. xv. During this period he found time to prepare a small medical work, De Peste, and certain historical studies, details of which appear in the Appendix. There are other works by Agricola referred to by sixteenth century writers, but so far we have not been able to find them although they may exist. Such data as we have, is given in the appendix.

As a young man, Agricola seems to have had some tendencies toward liberalism in religious matters, for while at Zwickau he composed some anti-Popish Epigrams; but after his return to Leipsic he apparently never wavered, and steadily refused to accept the Lutheran Reformation. To many even liberal scholars of the day, Luther's doctrines appeared wild and demagogic. Luther was not a scholarly man; his addresses were to the masses; his Latin was execrable. Nor did the bitter dissensions over hair-splitting theology in the Lutheran Church after Luther's death tend to increase respect for the movement among the learned. Agricola was a scholar of wide attainments, a deep-thinking, religious man, and he remained to the end a staunch Catholic, despite the general change of sentiment among his countrymen. His leanings were toward such men as his friend the humanist, Erasmus. That he had the courage of his convictions is shown in the dedication of De Natura Eorum, where he addresses to his friend, Duke Maurice, the pious advice that the dissensions of the Germans should be composed, and that the Duke should return to the bosom of the Church those who had been torn from her, and adds: "Yet I do not wish to become confused by these turbulent waters, and be led to offend anyone. It is more advisable to check my utterances." As he became older he may have become less tolerant in religious matters, for he did not seem to show as much patience in the discussion of ecclesiastical topics as he must have possessed earlier, yet he maintained to the end the respect and friendship of such great Protestants as Melanchthon, Camerarius, Fabricius, and many others.

In 1546, when he was at the age of 52, began Agricola's activity in public life, for in that year he was elected a Burgher of Chemnitz; and in the same year Duke Maurice appointed him Burgomaster—an office which he held for four terms. Before one can gain an insight into his political services, and incidentally into the character of the man, it is necessary to understand the politics of the time and his part therein, and to bear in mind always that he was a staunch Catholic under a Protestant Sovereign in a State seething with militant Protestantism.

Saxony had been divided in 1485 between the Princes Ernest and Albert, the former taking the Electoral dignity and the major portion of the Principality. Albert the Brave, the younger brother and Duke of Saxony, obtained the subordinate portion, embracing Meissen, but subject to the Elector. The Elector Ernest was succeeded in 1486 by Frederick the Wise, and under [Pg ix]his support Luther made Saxony the cradle of the Reformation. This Elector was succeeded in 1525 by his brother John, who was in turn succeeded by his son John Frederick in 1532. Of more immediate interest to this subject is the Albertian line of Saxon Dukes who ruled Meissen, for in that Principality Agricola was born and lived, and his political fortunes were associated with this branch of the Saxon House. Albert was succeeded in 1505 by his son George, "The Bearded," and he in turn by his brother Henry, the last of the Catholics, in 1539, who ruled until 1541. Henry was succeeded in 1541 by his Protestant son Maurice, who was the Patron of Agricola.

At about this time Saxony was drawn into the storms which rose from the long-standing rivalry between Francis I., King of France, and Charles V. of Spain. These two potentates came to the throne in the same year (1515), and both were candidates for Emperor of that loose Confederation known as the Holy Roman Empire. Charles was elected, and intermittent wars between these two Princes arose—first in one part of Europe, and then in another. Francis finally formed an alliance with the Schmalkalden League of German Protestant Princes, and with the Sultan of Turkey, against Charles. In 1546 Maurice of Meissen, although a Protestant, saw his best interest in a secret league with Charles against the other Protestant Princes, and proceeded (the Schmalkalden War) to invade the domains of his superior and cousin, the Elector Frederick. The Emperor Charles proved successful in this war, and Maurice was rewarded, at the Capitulation of Wittenberg in 1547, by being made Elector of Saxony in the place of his cousin. Later on, the Elector Maurice found the association with Catholic Charles unpalatable, and joined in leading the other Protestant princes in war upon him, and on the defeat of the Catholic party and the peace of Passau, Maurice became acknowledged as the champion of German national and religious freedom. He was succeeded by his brother Augustus in 1553.

Agricola was much favoured by the Saxon Electors, Maurice and Augustus. He dedicates most of his works to them, and shows much gratitude for many favours conferred upon him. Duke Maurice presented to him a house and plot in Chemnitz, and in a letter dated June 14th, 1543[9] in connection therewith, says: "... that he may enjoy his life-long a freehold house unburdened by all burgher rights and other municipal service, to be used by him and inhabited as a free dwelling, and that he may also, for the necessities of his household and of his wife and servants, brew his own beer free, and that he may likewise purvey for himself and his household foreign beer and also wine for use, and yet he shall not sell any such beer.... We have taken the said Doctor under our especial protection and care for our life-long, and he shall not be summoned before any Court of Justice, but only before us and our Councillor...."

Agricola was made Burgomaster of Chemnitz in 1546. A letter[10] from Fabricius to Meurer, dated May 19th, 1546, says that Agricola had been [Pg x]made Burgomaster by the command of the Prince. This would be Maurice, and it is all the more a tribute to the high respect with which Agricola was held, for, as said before, he was a consistent Catholic, and Maurice a Protestant Prince. In this same year the Schmalkalden War broke out, and Agricola was called to personal attendance upon the Duke Maurice in a diplomatic and advisory capacity. In 1546 also he was a member of the Diet of Freiberg, and was summoned to Council in Dresden. The next year he continued, by the Duke's command, Burgomaster at Chemnitz, although he seems to have been away upon Ducal matters most of the time. The Duke addresses[11] the Chemnitz Council in March, 1547: "We hereby make known to you that we are in urgent need of your Burgomaster, Dr. Georgius Agricola, with us. It is, therefore, our will that you should yield him up and forward him that he should with the utmost haste set forth to us here near Freiberg." He was sent on various missions from the Duke to the Emperor Charles, to King Ferdinand of Austria, and to other Princes in matters connected with the war—the fact that he was a Catholic probably entering into his appointment to such missions. Chemnitz was occupied by the troops of first one side, then the other, despite the great efforts of Agricola to have his own town specially defended. In April, 1547, the war came to an end in the Battle of Mühlberg, but Agricola was apparently not relieved of his Burgomastership until the succeeding year, for he wrote his friend Wolfgang Meurer, in April, 1548,[12] that he "was now relieved." His public duties did not end, however, for he attended the Diet of Leipzig in 1547 and in 1549, and was at the Diet at Torgau in 1550. In 1551 he was again installed as Burgomaster; and in 1553, for the fourth time, he became head of the Municipality, and during this year had again to attend the Diets at Leipzig and Dresden, representing his city. He apparently now had a short relief from public duties, for it is not until 1555, shortly before his death, that we find him again attending a Diet at Torgau.

Agricola died on November 21st, 1555. A letter[13] from his life-long friend, Fabricius, to Melanchthon, announcing this event, states: "We lost, on November 21st, that distinguished ornament of our Fatherland, Georgius Agricola, a man of eminent intellect, of culture and of judgment. He attained the age of 62. He who since the days of childhood had enjoyed robust health was carried off by a four-days' fever. He had previously suffered from no disease except inflammation of the eyes, which he brought upon himself by untiring study and insatiable reading.... I know that you loved the soul of this man, although in many of his opinions, more especially in religious and spiritual welfare, he differed in many points from our own. For he despised our Churches, and would not be with us in the Communion of the Blood of Christ. Therefore, after his death, at the command of the Prince, which was given to the Church inspectors and carried out by Tettelbach as a loyal servant, burial was refused him, and not [Pg xi]until the fourth day was he borne away to Zeitz and interred in the Cathedral.... I have always admired the genius of this man, so distinguished in our sciences and in the whole realm of Philosophy—yet I wonder at his religious views, which were compatible with reason, it is true, and were dazzling, but were by no means compatible with truth.... He would not tolerate with patience that anyone should discuss ecclesiastical matters with him." This action of the authorities in denying burial to one of their most honoured citizens, who had been ever assiduous in furthering the welfare of the community, seems strangely out of joint. Further, the Elector Augustus, although a Protestant Prince, was Agricola's warm friend, as evidenced by his letter of but a few months before (see p. xv). However, Catholics were then few in number at Chemnitz, and the feeling ran high at the time, so possibly the Prince was afraid of public disturbances. Hofmann[14] explains this occurrence in the following words:—"The feelings of Chemnitz citizens, who were almost exclusively Protestant, must certainly be taken into account. They may have raised objections to the solemn interment of a Catholic in the Protestant Cathedral Church of St. Jacob, which had, perhaps, been demanded by his relatives, and to which, according to the custom of the time, he would have been entitled as Burgomaster. The refusal to sanction the interment aroused, more especially in the Catholic world, a painful sensation."

A brass memorial plate hung in the Cathedral at Zeitz had already disappeared in 1686, nor have the cities of his birth or residence ever shown any appreciation of this man, whose work more deserves their gratitude than does that of the multitude of soldiers whose monuments decorate every village and city square. It is true that in 1822 a marble tablet was placed behind the altar in the Church of St. Jacob in Chemnitz, but even this was removed to the Historical Museum later on.

He left a modest estate, which was the subject of considerable litigation by his descendants, due to the mismanagement of the guardian. Hofmann has succeeded in tracing the descendants for two generations, down to 1609, but the line is finally lost among the multitude of other Agricolas.

To deduce Georgius Agricola's character we need not search beyond the discovery of his steadfast adherence to the religion of his fathers amid the bitter storm of Protestantism around him, and need but to remember at the same time that for twenty-five years he was entrusted with elective positions of an increasingly important character in this same community. No man could have thus held the respect of his countrymen unless he were devoid of bigotry and possessed of the highest sense of integrity, justice, humanity, and patriotism.

Agricola's education was the most thorough that his times afforded in the classics, philosophy, medicine, and sciences generally. Further, his writings disclose a most exhaustive knowledge not only of an extraordinary range of classical literature, but also of obscure manuscripts buried in the public libraries of Europe. That his general learning was held to be of a high order is amply evidenced from the correspondence of the other scholars of his time—Erasmus, Melanchthon, Meurer, Fabricius, and others.

Our more immediate concern, however, is with the advances which were due to him in the sciences of Geology, Mineralogy, and Mining Engineering. No appreciation of these attainments can be conveyed to the reader unless he has some understanding of the dearth of knowledge in these sciences prior to Agricola's time. We have in Appendix B given a brief review of the literature extant at this period on these subjects. Furthermore, no appreciation of Agricola's contribution to science can be gained without a study of De Ortu et Causis and De Natura Fossilium, for while De Re Metallica is of much more general interest, it contains but incidental reference to Geology and Mineralogy. Apart from the book of Genesis, the only attempts at fundamental explanation of natural phenomena were those of the Greek Philosophers and the Alchemists. Orthodox beliefs Agricola scarcely mentions; with the Alchemists he had no patience. There can be no doubt, however, that his views are greatly coloured by his deep classical learning. He was in fine to a certain distance a follower of Aristotle, Theophrastus, Strato, and other leaders of the Peripatetic school. For that matter, except for the muddy current which the alchemists had introduced into this already troubled stream, the whole thought of the learned world still flowed from the Greeks. Had he not, however, radically departed from the teachings of the Peripatetic school, his work would have been no contribution to the development of science. Certain of their teachings he repudiated with great vigour, and his laboured and detailed arguments in their refutation form the first battle in science over the results of observation versus inductive speculation. To use his own words: "Those things which we see with our eyes and understand by means of our senses are more clearly to be demonstrated than if learned by means of reasoning."[15] The bigoted scholasticism of his times necessitated as much care and detail in refutation of such deep-rooted beliefs, as would be demanded to-day by an attempt at a refutation of the theory of evolution, and in consequence his works are often but dry reading to any but those interested in the development of fundamental scientific theory.

In giving an appreciation of Agricola's views here and throughout the footnotes, we do not wish to convey to the reader that he was in all things free from error and from the spirit of his times, or that his theories, constructed long before the atomic theory, are of the clear-cut order which that basic hypothesis has rendered possible to later scientific speculation in these branches. His statements are sometimes much confused, but we reiterate that [Pg xiii]their clarity is as crystal to mud in comparison with those of his predecessors—and of most of his successors for over two hundred years. As an indication of his grasp of some of the wider aspects of geological phenomena we reproduce, in Appendix A, a passage from De Ortu et Causis, which we believe to be the first adequate declaration of the part played by erosion in mountain sculpture. But of all of Agricola's theoretical views those are of the greatest interest which relate to the origin of ore deposits, for in these matters he had the greatest opportunities of observation and the most experience. We have on page 108 reproduced and discussed his theory at considerable length, but we may repeat here, that in his propositions as to the circulation of ground waters, that ore channels are a subsequent creation to the contained rocks, and that they were filled by deposition from circulating solutions, he enunciated the foundations of our modern theory, and in so doing took a step in advance greater than that of any single subsequent authority. In his contention that ore channels were created by erosion of subterranean waters he was wrong, except for special cases, and it was not until two centuries later that a further step in advance was taken by the recognition by Van Oppel of the part played by fissuring in these phenomena. Nor was it until about the same time that the filling of ore channels in the main by deposition from solutions was generally accepted. While Werner, two hundred and fifty years after Agricola, is generally revered as the inspirer of the modern theory by those whose reading has taken them no farther back, we have no hesitation in asserting that of the propositions of each author, Agricola's were very much more nearly in accord with modern views. Moreover, the main result of the new ideas brought forward by Werner was to stop the march of progress for half a century, instead of speeding it forward as did those of Agricola.

In mineralogy Agricola made the first attempt at systematic treatment of the subject. His system could not be otherwise than wrongly based, as he could scarcely see forward two or three centuries to the atomic theory and our vast fund of chemical knowledge. However, based as it is upon such properties as solubility and homogeneity, and upon external characteristics such as colour, hardness, &c., it makes a most creditable advance upon Theophrastus, Dioscorides, and Albertus Magnus—his only predecessors. He is the first to assert that bismuth and antimony are true primary metals; and to some sixty actual mineral species described previous to his time he added some twenty more, and laments that there are scores unnamed.

As to Agricola's contribution to the sciences of mining and metallurgy, De Re Metallica speaks for itself. While he describes, for the first time, scores of methods and processes, no one would contend that they were discoveries or inventions of his own. They represent the accumulation of generations of experience and knowledge; but by him they were, for the first time, to receive detailed and intelligent exposition. Until Schlüter's work nearly two centuries later, it was not excelled. There is no measure by which we may gauge the value of such a work to the men who followed in this profession during centuries, nor the benefits enjoyed by humanity through them.

That Agricola occupied a very considerable place in the great awakening of learning will be disputed by none except by those who place the development of science in rank far below religion, politics, literature, and art. Of wider importance than the details of his achievements in the mere confines of the particular science to which he applied himself, is the fact that he was the first to found any of the natural sciences upon research and observation, as opposed to previous fruitless speculation. The wider interest of the members of the medical profession in the development of their science than that of geologists in theirs, has led to the aggrandizement of Paracelsus, a contemporary of Agricola, as the first in deductive science. Yet no comparative study of the unparalleled egotistical ravings of this half-genius, half-alchemist, with the modest sober logic and real research and observation of Agricola, can leave a moment's doubt as to the incomparably greater position which should be attributed to the latter as the pioneer in building the foundation of science by deduction from observed phenomena. Science is the base upon which is reared the civilization of to-day, and while we give daily credit to all those who toil in the superstructure, let none forget those men who laid its first foundation stones. One of the greatest of these was Georgius Agricola.

Agricola seems to have been engaged in the preparation of De Re Metallica for a period of over twenty years, for we first hear of the book in a letter from Petrus Plateanus, a schoolmaster at Joachimsthal, to the great humanist, Erasmus,[16] in September, 1529. He says: "The scientific world will be still more indebted to Agricola when he brings to light the books De Re Metallica and other matters which he has on hand." In the dedication of De Mensuris et Ponderibus (in 1533) Agricola states that he means to publish twelve books De Re Metallica, if he lives. That the appearance of this work was eagerly anticipated is evidenced by a letter from George Fabricius to Valentine Hertel:[17] "With great excitement the books De Re Metallica are being awaited. If he treats the material at hand with his usual zeal, he will win for himself glory such as no one in any of the fields of literature has attained for the last thousand years." According to the dedication of De Veteribus et Novis Metallis, Agricola in 1546 already looked forward to its early publication. The work was apparently finished in 1550, for the dedication to the Dukes Maurice and August of Saxony is dated in December of that year. The eulogistic poem by his friend, George Fabricius, is dated in 1551.

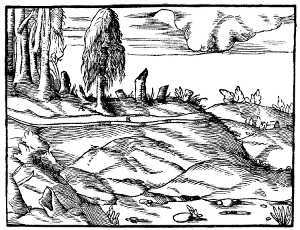

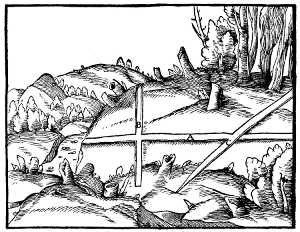

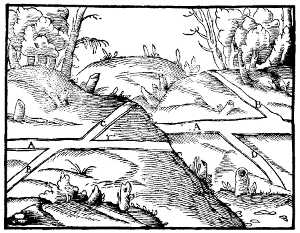

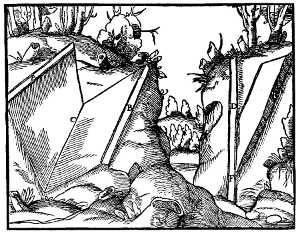

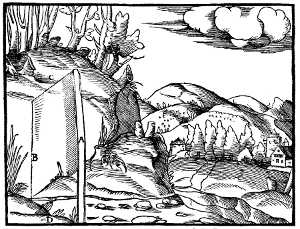

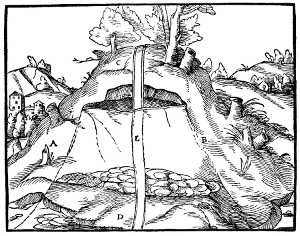

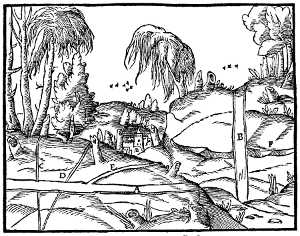

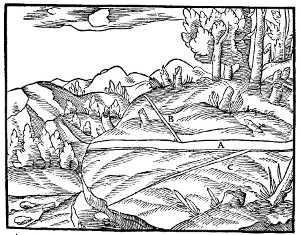

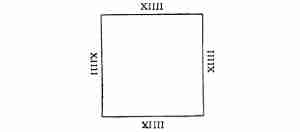

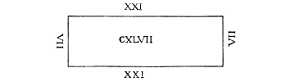

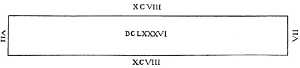

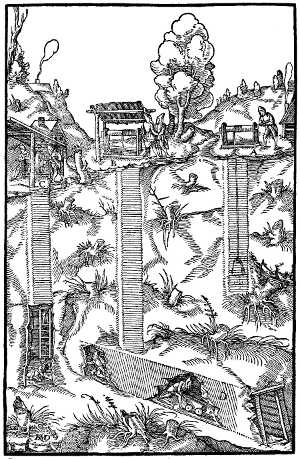

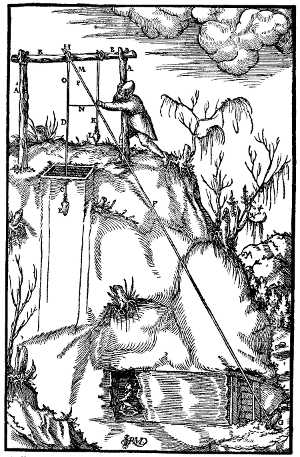

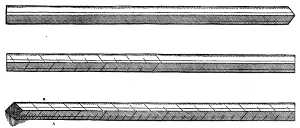

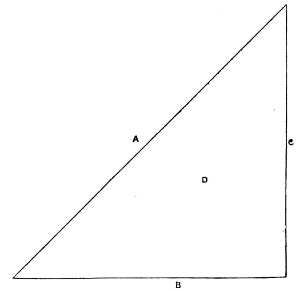

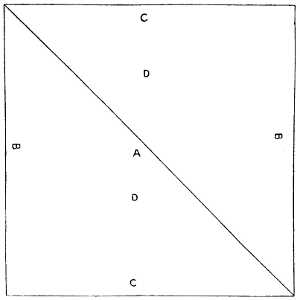

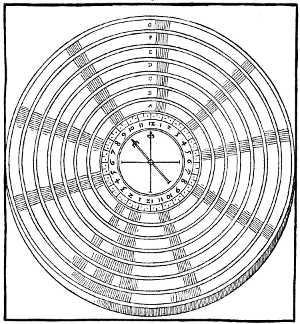

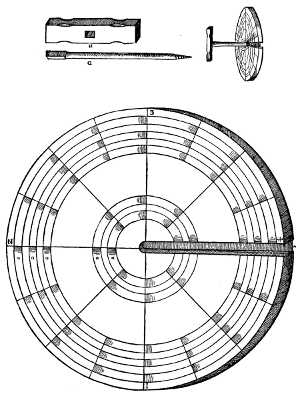

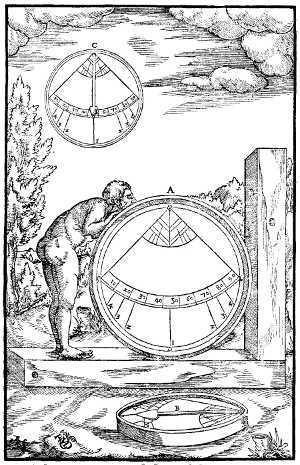

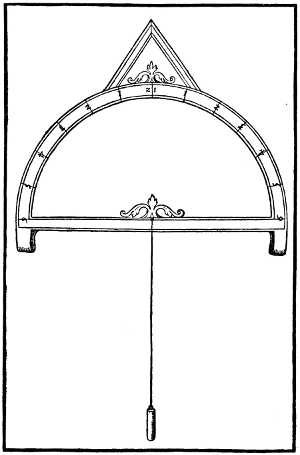

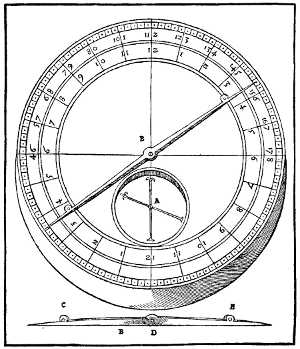

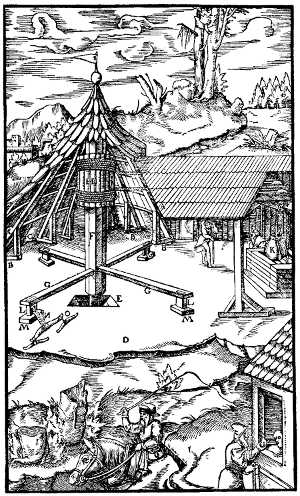

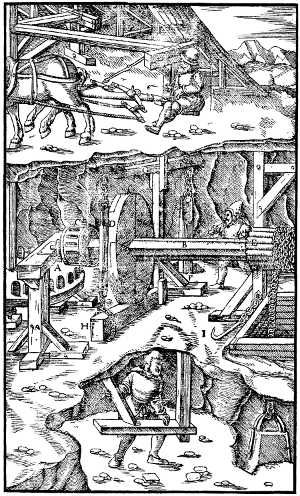

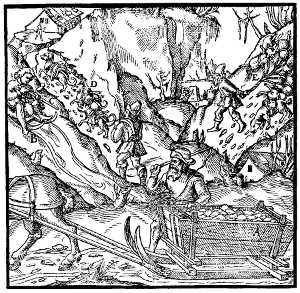

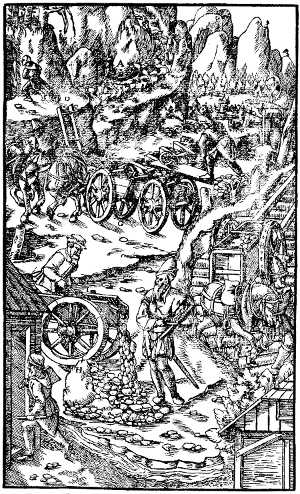

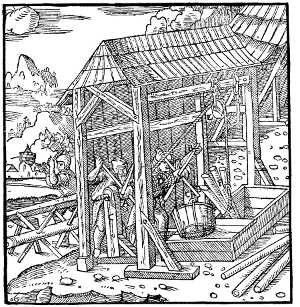

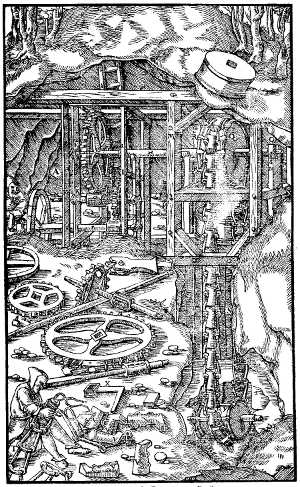

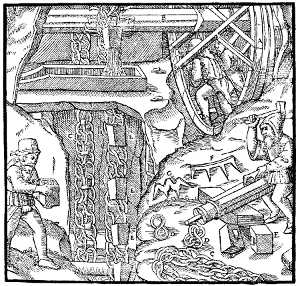

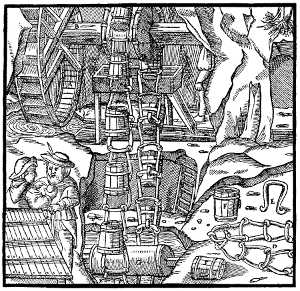

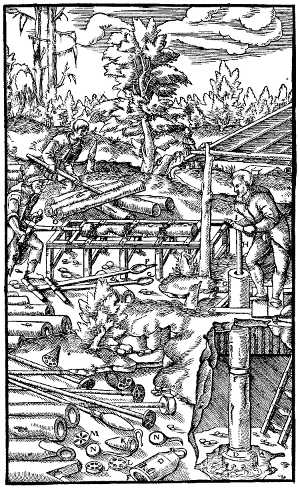

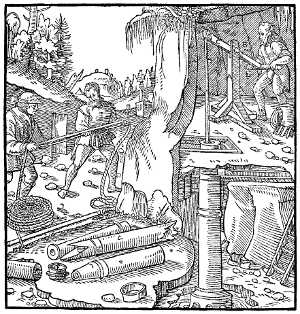

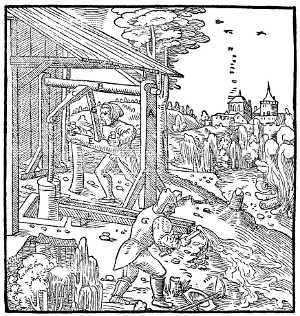

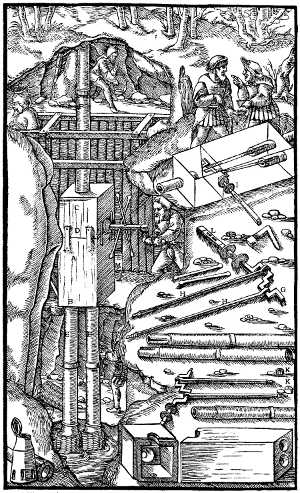

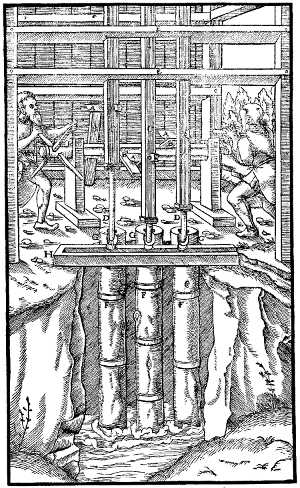

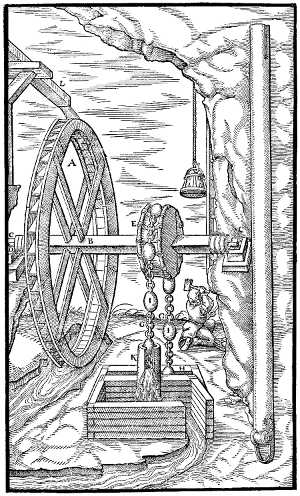

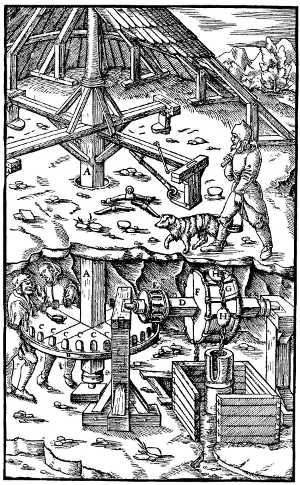

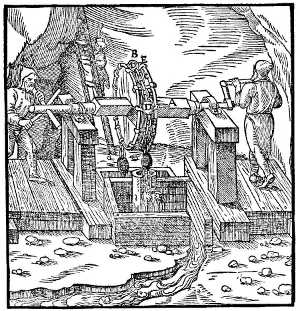

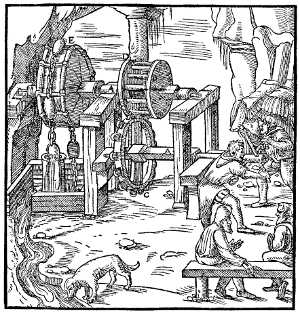

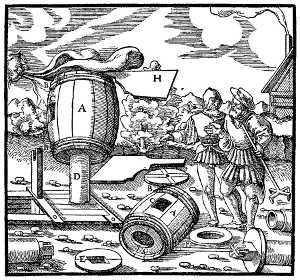

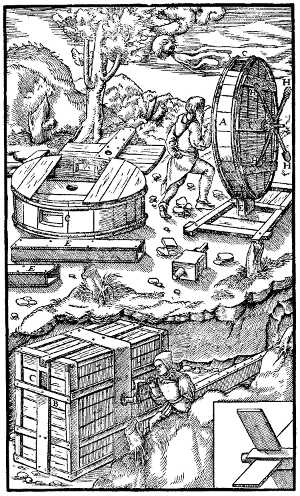

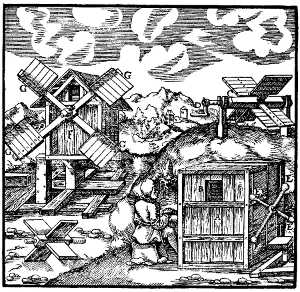

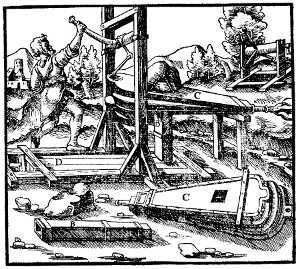

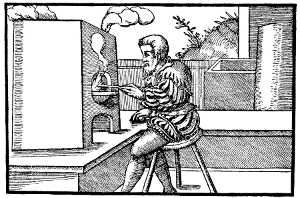

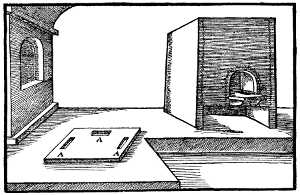

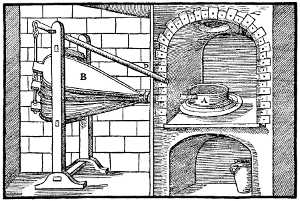

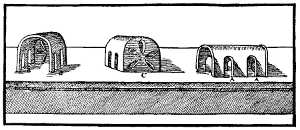

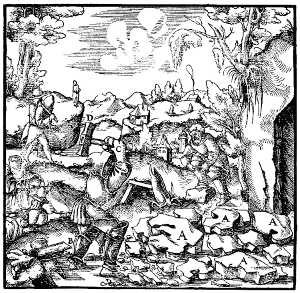

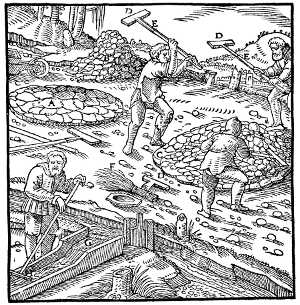

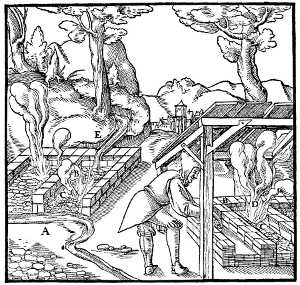

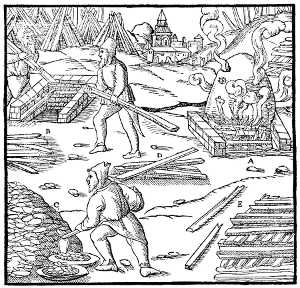

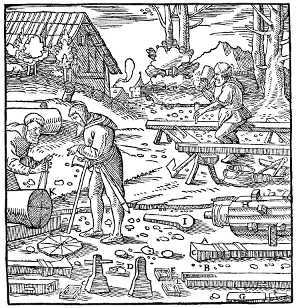

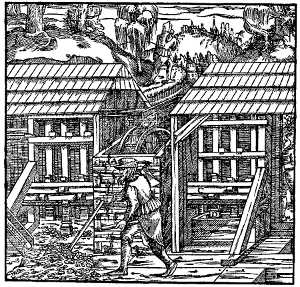

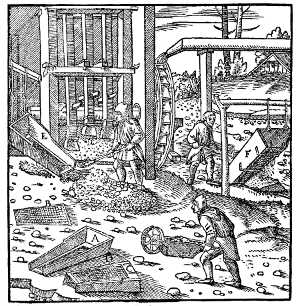

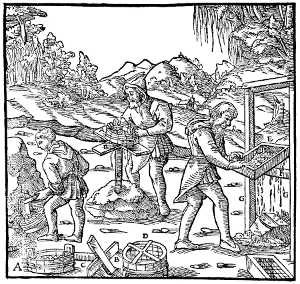

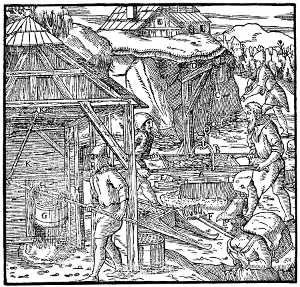

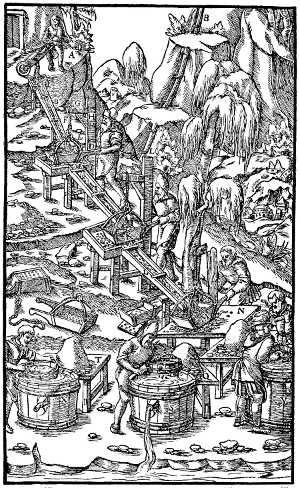

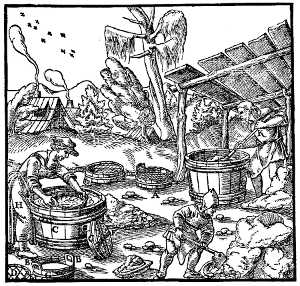

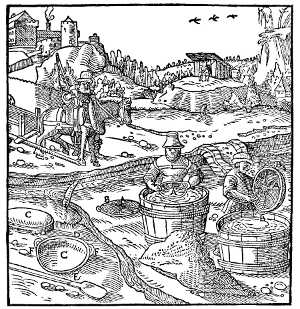

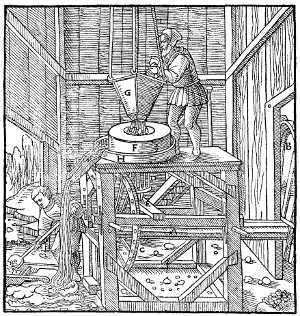

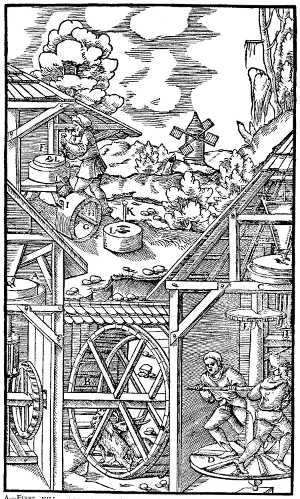

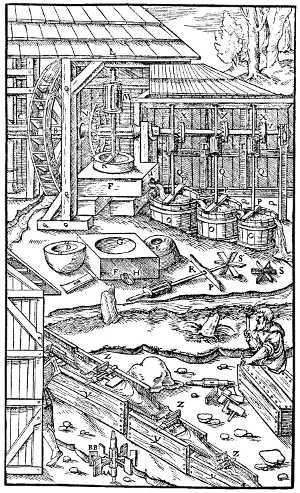

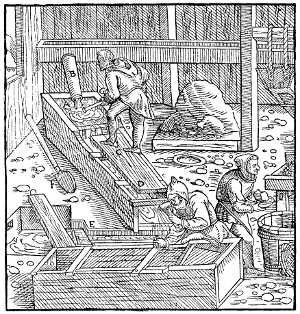

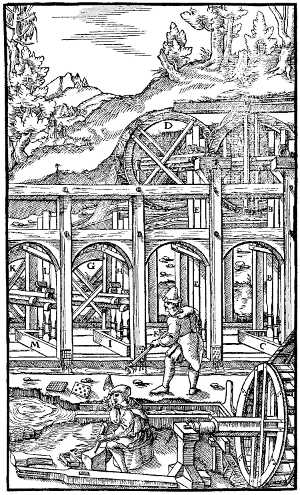

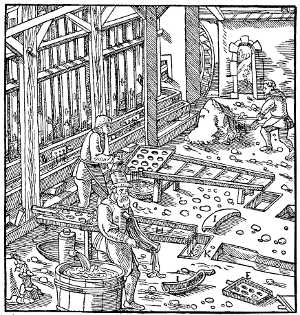

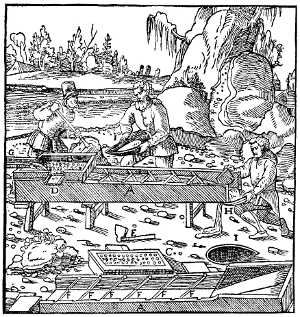

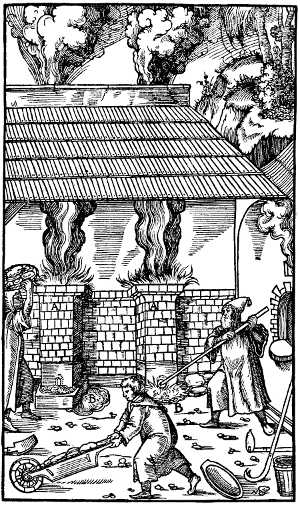

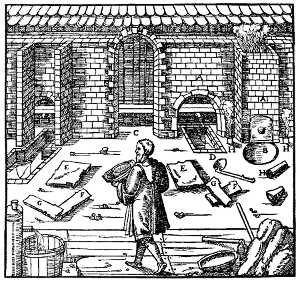

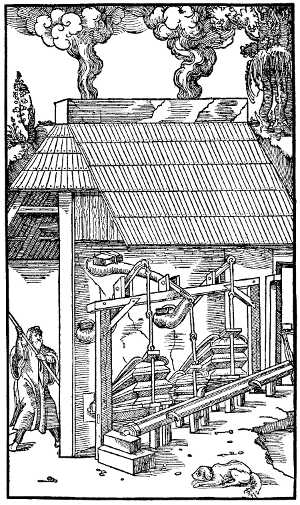

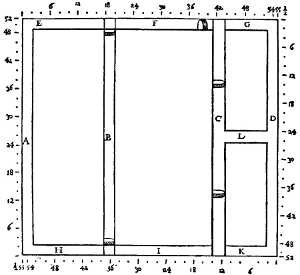

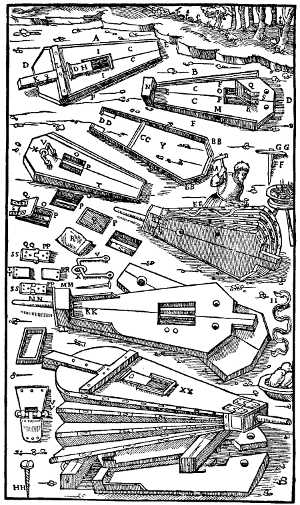

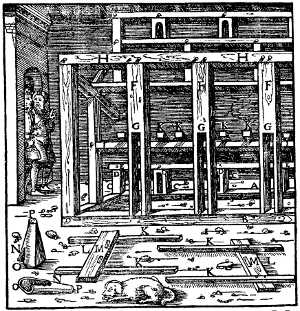

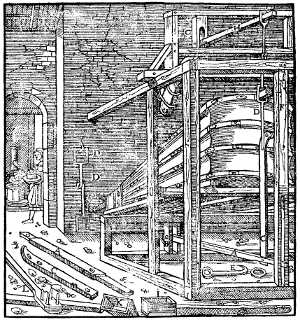

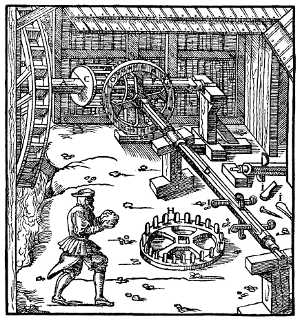

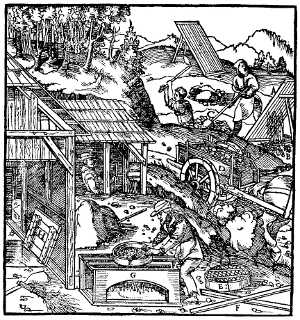

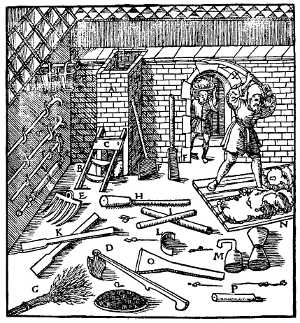

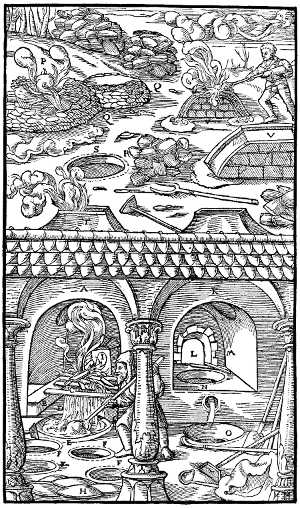

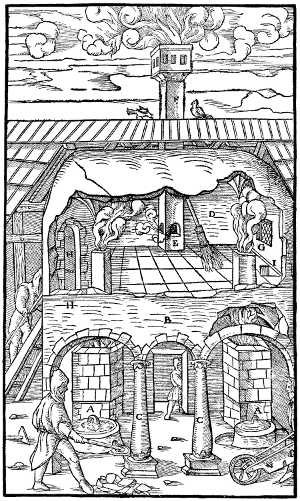

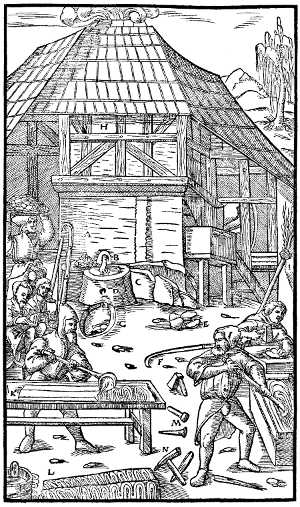

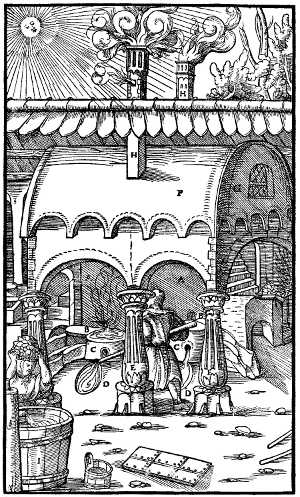

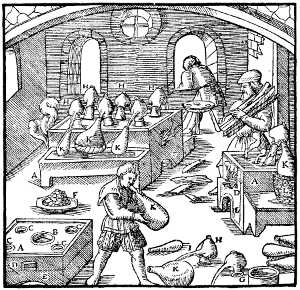

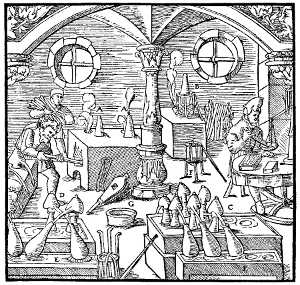

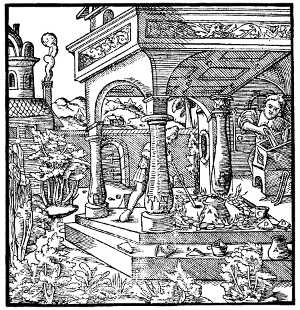

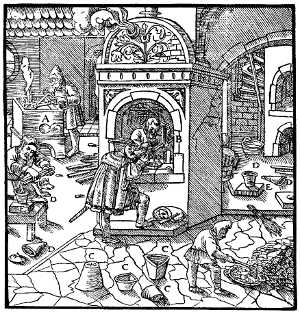

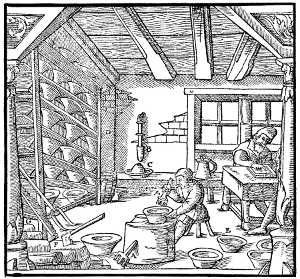

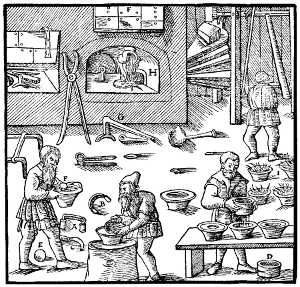

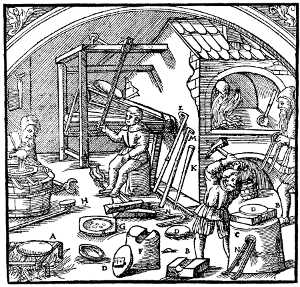

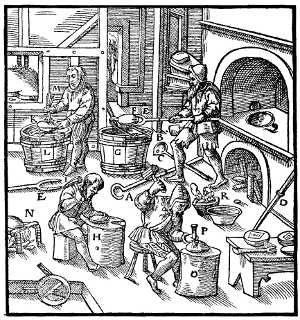

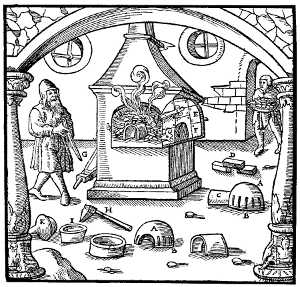

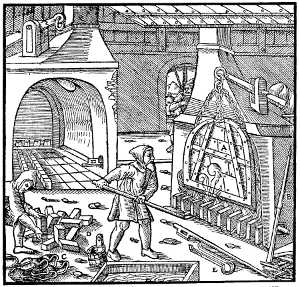

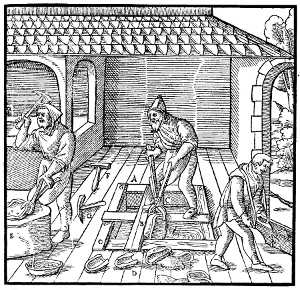

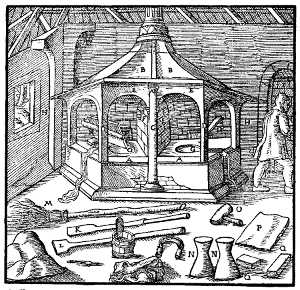

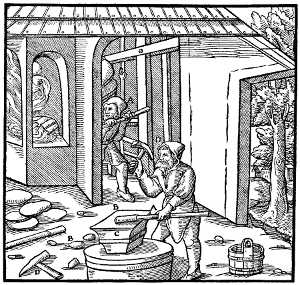

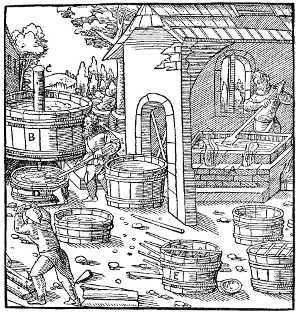

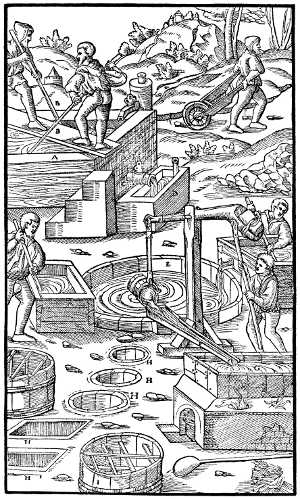

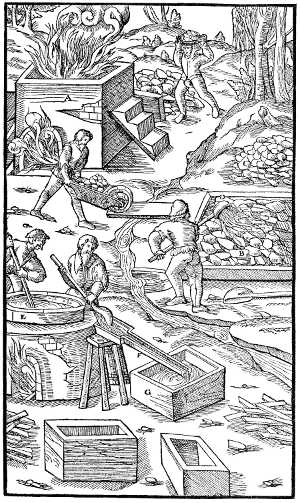

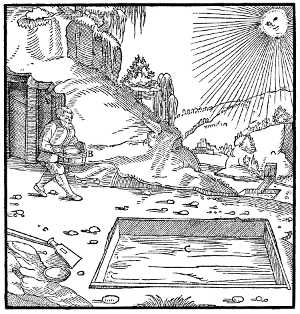

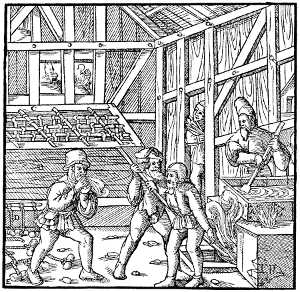

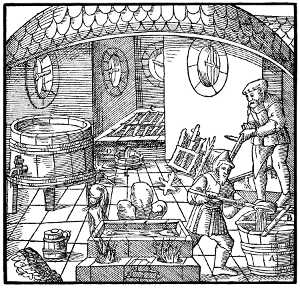

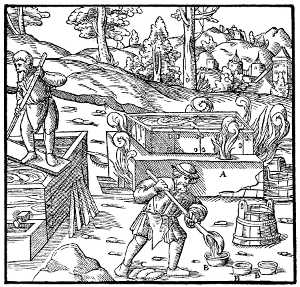

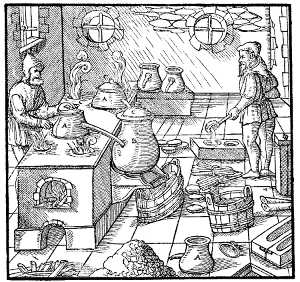

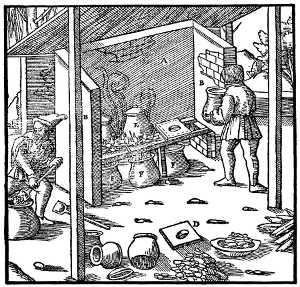

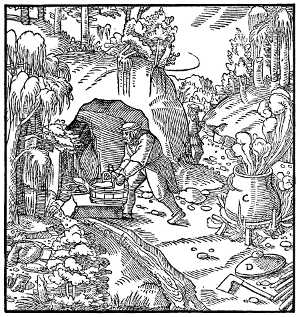

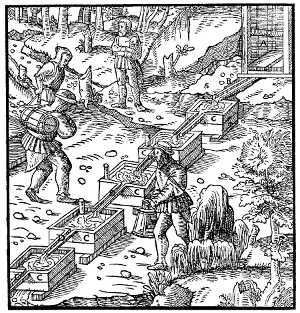

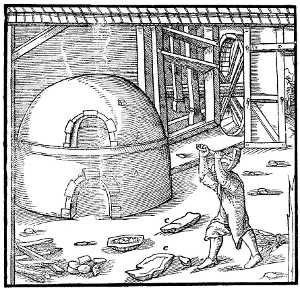

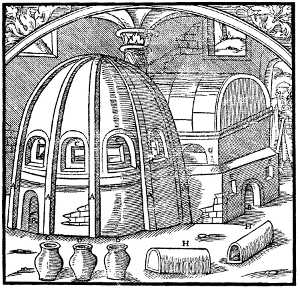

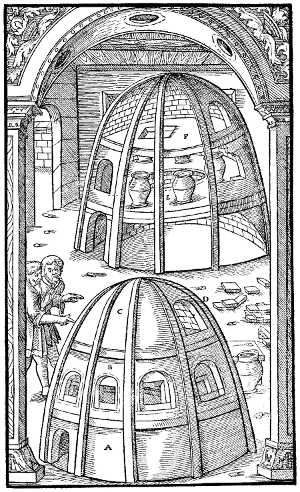

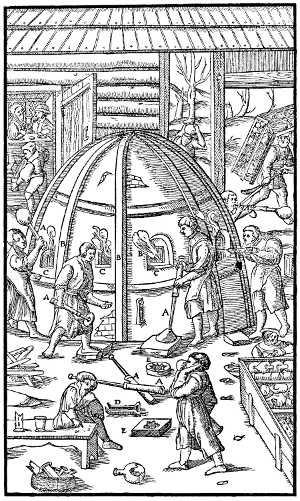

The publication was apparently long delayed by the preparation of the woodcuts; and, according to Mathesius,[18] many sketches for them were prepared by Basilius Wefring. In the preface of De Re Metallica, Agricola does not mention who prepared the sketches, but does say: "I have hired illustrators to delineate their forms, lest descriptions which are conveyed by words should either not be understood by men of our own times, or should cause difficulty to posterity." In 1553 the completed book was sent to Froben for publication, for a letter[19] from Fabricius to Meurer in March, 1553, announces its dispatch to the printer. An interesting letter[20] from the Elector Augustus to Agricola, dated January 18, 1555, reads: "Most learned, dear and faithful subject, whereas you have sent to the Press a Latin book of which the title is said to be De Rebus Metallicis, which has been praised to us and we should like to know the contents, it is our gracious command that you should get the book translated when you have the opportunity into German, and not let it be copied more than once or be printed, but keep it by you and send us a copy. If you should need a writer for this purpose, we will provide one. Thus you will fulfil our gracious behest." The German translation was prepared by Philip Bechius, a Basel University Professor of Medicine and Philosophy. It is a wretched work, by one who knew nothing of the science, and who more especially had no appreciation of the peculiar Latin terms coined by Agricola, most of which [Pg xvi]he rendered literally. It is a sad commentary on his countrymen that no correct German translation exists. The Italian translation is by Michelangelo Florio, and is by him dedicated to Elizabeth, Queen of England. The title page of the first edition is reproduced later on, and the full titles of other editions are given in the Appendix, together with the author's other works. The following are the short titles of the various editions of De Re Metallica, together with the name and place of the publisher:—

Latin Editions.

| De Re Metallica, | Froben | Basel Folio | 1556. |

| " | " | " | 1561. |

| " | Ludwig König | " | 1621. |

| " | Emanuel König | " | 1657. |

In addition to these, Leupold,[21] Schmid,[22] and others mention an octavo edition, without illustrations, Schweinfurt, 1607. We have not been able to find a copy of this edition, and are not certain of its existence. The same catalogues also mention an octavo edition of De Re Metallica, Wittenberg, 1612 or 1614, with notes by Joanne Sigfrido; but we believe this to be a confusion with Agricola's subsidiary works, which were published at this time and place, with such notes.

German Editions.

| Vom Bergkwerck, | Froben, Folio, 1557. |

| Bergwerck Buch, | Sigmundi Feyrabendt, Frankfort-on-Main, folio, 1580. |

| " | Ludwig König, Basel, folio, 1621. |

There are other editions than these, mentioned by bibliographers, but we have been unable to confirm them in any library. The most reliable of such bibliographies, that of John Ferguson,[23] gives in addition to the above; Bergwerkbuch, Basel, 1657, folio, and Schweinfurt, 1687, octavo.

Italian Edition.

L'Arte de Metalli, Froben, Basel, folio, 1563.

Other Languages.

So far as we know, De Re Metallica was never actually published in other than Latin, German, and Italian. However, a portion of the accounts of the firm of Froben were published in 1881[24], and therein is an entry under March, 1560, of a sum to one Leodigaris Grymaldo for some other work, and also for "correction of Agricola's De Re Metallica in French." This may of course, be an error for the Italian edition, which appeared a little later. There is also mention[25] that a manuscript of De Re Metallica in Spanish was [Pg xvii]seen in the library of the town of Bejar. An interesting note appears in the glossary given by Sir John Pettus in his translation of Lazarus Erckern's work on assaying. He says[26] "but I cannot enlarge my observations upon any more words, because the printer calls for what I did write of a metallick dictionary, after I first proposed the printing of Erckern, but intending within the compass of a year to publish Georgius Agricola, De Re Metallica (being fully translated) in English, and also to add a dictionary to it, I shall reserve my remaining essays (if what I have done hitherto be approved) till then, and so I proceed in the dictionary." The translation was never published and extensive inquiry in various libraries and among the family of Pettus has failed to yield any trace of the manuscript.

[Pg v][1] For the biographical information here set out we have relied principally upon the following works:—Petrus Albinus, Meissnische Land Und Berg Chronica, Dresden, 1590; Adam Daniel Richter, Umständliche ... Chronica der Stadt Chemnitz, Leipzig, 1754; Johann Gottfried Weller, Altes Aus Allen Theilen Der Geschichte, Chemnitz, 1766; Freidrich August Schmid, Georg Agrikola's Bermannus, Freiberg, 1806; Georg Heinrich Jacobi, Der Mineralog Georgius Agricola, Zwickau, 1881; Dr. Reinhold Hofmann, Dr. Georg Agricola, Gotha, 1905. The last is an exhaustive biographical sketch, to which we refer those who are interested.

[Pg vi][2] Georgii Agricolae Glaucii Libellus de Prima ac Simplici Institutione Grammatica, printed by Melchior Lotther, Leipzig, 1520. Petrus Mosellanus refers to this work (without giving title) in a letter to Agricola, June, 1520.

[3] Briefe an Desiderius Erasmus von Rotterdam. Published by Joseph Förstemann and Otto Günther. XXVII. Beiheft zum Zentralblatt für Bibliothekswesen, Leipzig, 1904. p. 44.

[4] De Veteribus et Novis Metallis. Preface.

[5] A summary of this and of Agricola's other works is given in the Appendix A.

[7] Printed in F. A. Schmid's Georg Agrikola's Bermannus, p. 14, Freiberg, 1806.

[8] Op. Cit., p. 8.

[10] Baumgarten-Crusius. Georgii Fabricii Chemnicensis Epistolae ad W. Meurerum et Alios Aequales, Leipzig, 1845, p. 26.

[12] Weber, Virorum Clarorum Saeculi XVI. et XVII. Epistolae Selectae, Leipzig, 1894, p. 8.

[13] Baumgarten-Crusius. Op. cit., p. 139.

[Pg xv][16] Briefe an Desiderius Erasmus von Rotterdam. Published by Joseph Förstemann & Otto Günther. XXVII. Beiheft zum Zentralblatt für Bibliothekswesen, Leipzig, 1904, p. 125.

[17] Petrus Albinus, Meissnische Land und Berg Chronica, Dresden, 1590, p. 353.

[18] This statement is contained under "1556" in a sort of chronicle bound up with Mathesius's Sarepta, Nuremberg, 1562.

[19] Baumgarten-Crusius, p. 85, letter No. 93.

[20] Principal State Archives, Dresden, Cop. 259, folio 102.

[22] F. A. Schmid, Georg Agrikola's Bermannus, Freiberg, 1806, p. 34.

[23] Bibliotheca Chemica, Glasgow, 1906, p. 10.

[24] Rechnungsbuch der Froben und Episcopius Buchdrucker und Buchhändler zu Basel, 1557-1564, published by R. Wackernagle, Basel, 1881. p. 20.

[25] Colecion del Sr Monoz t. 93, fol. 255 En la Acad. de la Hist. Madrid.

AD LECTOREM.

Misenæ M. D. LI.

èludo illustri.

[Pg xxiv][1] For completeness' sake we reproduce in the original Latin the laudation of Agricola by his friend, Georgius Fabricius, a leading scholar of his time. It has but little intrinsic value for it is not poetry of a very high order, and to make it acceptable English would require certain improvements, for which only poets have licence. A "free" translation of the last few lines indicates its complimentary character:—

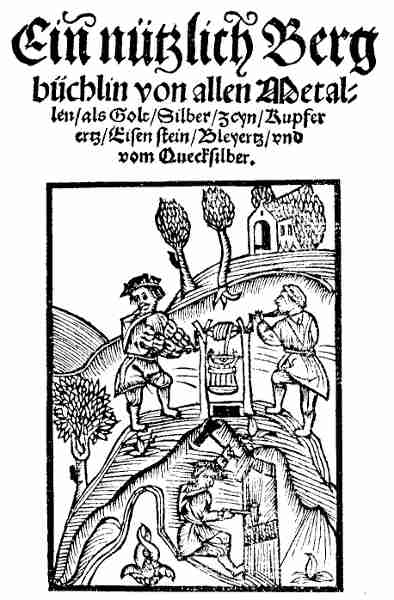

ost illustrious Princes, often have I considered the metallic arts as a whole, as Moderatus Columella[2] considered the agricultural arts, just as if I had been considering the whole of the human body; and when I had perceived the various parts of the subject, like so many members of the body, I became afraid that I might die before I should understand its full extent, much less before I could immortalise it in writing. This book itself indicates the length and breadth of the subject, and the number and importance of the sciences of which at least some little knowledge is necessary to miners. Indeed, the subject of mining is a very extensive one, and one very difficult to explain; no part of it is fully dealt with by the Greek and Latin authors whose works survive; and since the art is one of the most ancient, the most necessary and the most profitable to mankind, I considered that I ought not to neglect it. Without doubt, none of the arts is older than agriculture, but that of the metals is not less ancient; in fact they are at least equal and coeval, for no mortal man ever tilled a field without implements. In truth, in all the works of agriculture, as in the other arts, implements are used which are made from metals, or which could not be made without the use of metals; for this reason the metals are of the greatest necessity to man. When an art is so poor that it lacks metals, it is not of much importance, for nothing is made without tools. Besides, of all ways whereby great wealth is acquired by good and honest means, none is more advantageous than mining; for although from fields which are well tilled (not to mention other things) we derive rich yields, yet we obtain richer products from mines; in fact, one mine is often much more beneficial to us than many fields. For this reason we learn from the history of nearly all ages that very many men have been made rich by the [Pg xxvi]mines, and the fortunes of many kings have been much amplified thereby. But I will not now speak more of these matters, because I have dealt with these subjects partly in the first book of this work, and partly in the other work entitled De Veteribus et Novis Metallis, where I have refuted the charges which have been made against metals and against miners. Now, though the art of husbandry, which I willingly rank with the art of mining, appears to be divided into many branches, yet it is not separated into so many as this art of ours, nor can I teach the principles of this as easily as Columella did of that. He had at hand many writers upon husbandry whom he could follow,—in fact, there are more than fifty Greek authors whom Marcus Varro enumerates, and more than ten Latin ones, whom Columella himself mentions. I have only one whom I can follow; that is C. Plinius Secundus,[3] and he expounds only a very few methods of digging ores and of making metals. Far from the whole of the art having been treated by any one writer, those who have written occasionally on any one or another of its branches have not even dealt completely with a single one of them. Moreover, there is a great scarcity even of these, since alone of all the Greeks, Strato of Lampsacus,[4] the successor of Theophrastus,[5] wrote a book on the subject, De Machinis Metallicis; except, perhaps a work by the poet Philo, a small part of which embraced to some degree the occupation of mining.[6] Pherecrates seems to have introduced into his comedy, which was similar in title, miners as slaves or as persons condemned to serve in the mines. Of the Latin writers, Pliny, as I have already said, has described a few methods of working. Also among the authors I must include the modern writers, whosoever they are, for no one should escape just condemnation who fails to award due recognition to persons whose writings he uses, even very slightly. Two books have been written in our tongue; the one on the assaying of mineral substances and metals, somewhat confused, whose author is unknown[7]; the other "On Veins," of which Pandulfus Anglus[8] is also said to have written, although the German book was written by Calbus of Freiberg, a well-known doctor; but neither of them accomplished the task [Pg xxvii]he had begun.[9] Recently Vannucci Biringuccio, of Sienna, a wise man experienced in many matters, wrote in vernacular Italian on the subject of the melting, separating, and alloying of metals.[10] He touched briefly on the methods of smelting certain ores, and explained more fully the methods of making certain juices; by reading his directions, I have refreshed my memory of those things which I myself saw in Italy; as for many matters on which I write, he did not touch upon them at all, or touched but lightly. This book was given me by Franciscus Badoarius, a Patrician of Venice, and a man of wisdom and of repute; this he had promised that he would do, when in the previous year he was at Marienberg, having been sent by the Venetians as an Ambassador to King Ferdinand. Beyond these books I do not find any writings on the metallic arts. For that reason, even if the book of Strato existed, from all these sources not one-half of the whole body of the science of mining could be pieced together.

Seeing that there have been so few who have written on the subject of the metals, it appears to me all the more wonderful that so many alchemists have arisen who would compound metals artificially, and who would change one into another. Hermolaus Barbarus,[11] a man of high rank and station, and distinguished in all kinds of learning, has mentioned the names of many in his writings; and I will proffer more, but only famous ones, for I will limit myself to a few. Thus Osthanes has written on χυμευτικά and there are Hermes; Chanes; Zosimus, the Alexandrian, to his sister Theosebia; Olympiodorus, also an Alexandrian; Agathodæmon; Democritus, not the one of Abdera, but some other whom I know not; Orus Chrysorichites, Pebichius, Comerius, Joannes, Apulejus, Petasius, Pelagius, Africanus, Theophilus, Synesius, Stephanus to Heracleus Cæsar, Heliodorus to Theodosius, Geber, Callides Rachaidibus, Veradianus, Rodianus, Canides, Merlin, Raymond Lully, Arnold de Villa Nova, and Augustinus Pantheus of Venice; and three women, Cleopatra, the maiden Taphnutia, and Maria the Jewess.[12] All these alchemists employ obscure language, and Johanes Aurelius Augurellus of Rimini, alone has used the language of poetry. There are many other books on [Pg xxviii]this subject, but all are difficult to follow, because the writers upon these things use strange names, which do not properly belong to the metals, and because some of them employ now one name and now another, invented by themselves, though the thing itself changes not. These masters teach their disciples that the base metals, when smelted, are broken up; also they teach the methods by which they reduce them to the primary parts and remove whatever is superfluous in them, and by supplying what is wanted make out of them the precious metals—that is, gold and silver,—all of which they carry out in a crucible. Whether they can do these things or not I cannot decide; but, seeing that so many writers assure us with all earnestness that they have reached that goal for which they aimed, it would seem that faith might be placed in them; yet also seeing that we do not read of any of them ever having become rich by this art, nor do we now see them growing rich, although so many nations everywhere have produced, and are producing, alchemists, and all of them are straining every nerve night and day to the end that they may heap a great quantity of gold and silver, I should say the matter is dubious. But although it may be due to the carelessness of the writers that they have not transmitted to us the names of the masters who acquired great wealth through this occupation, certainly it is clear that their disciples either do not understand their precepts or, if they do understand them, do not follow them; for if they do comprehend them, seeing that these disciples have been and are so numerous, they would have by to-day filled [Pg xxix]whole towns with gold and silver. Even their books proclaim their vanity, for they inscribe in them the names of Plato and Aristotle and other philosophers, in order that such high-sounding inscriptions may impose upon simple people and pass for learning. There is another class of alchemists who do not change the substance of base metals, but colour them to represent gold or silver, so that they appear to be that which they are not, and when this appearance is taken from them by the fire, as if it were a garment foreign to them, they return to their own character. These alchemists, since they deceive people, are not only held in the greatest odium, but their frauds are a capital offence. No less a fraud, warranting capital punishment, is committed by a third sort of alchemists; these throw into a crucible a small piece of gold or silver hidden in a coal, and after mixing therewith fluxes which have the power of extracting it, pretend to be making gold from orpiment, or silver from tin and like substances. But concerning the art of alchemy, if it be an art, I will speak further elsewhere. I will now return to the art of mining.

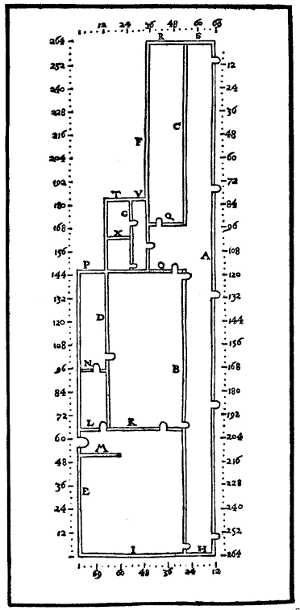

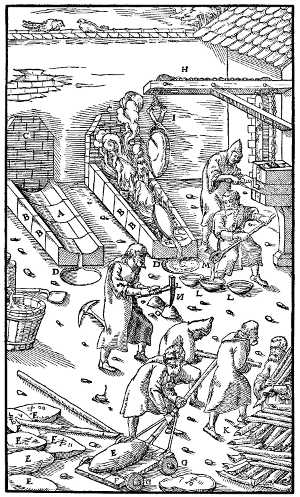

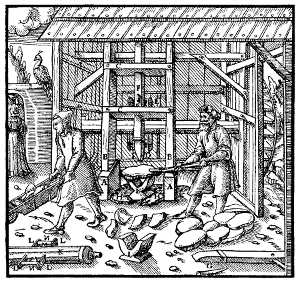

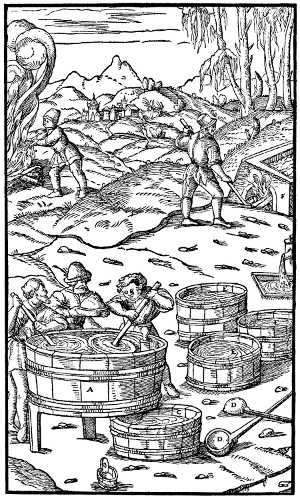

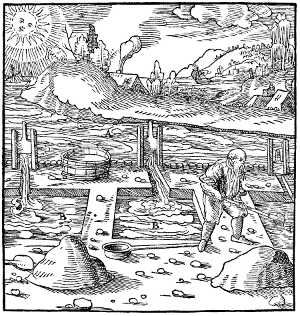

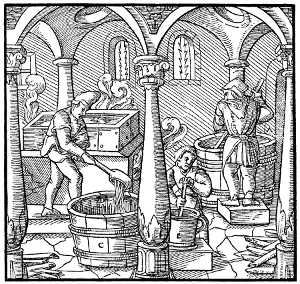

Since no authors have written of this art in its entirety, and since foreign nations and races do not understand our tongue, and, if they did understand it, would be able to learn only a small part of the art through the works of those authors whom we do possess, I have written these twelve books De Re Metallica. Of these, the first book contains the arguments which may be used against this art, and against metals and the mines, and what can be said in their favour. The second book describes the miner, and branches into [Pg xxx]a discourse on the finding of veins. The third book deals with veins and stringers, and seams in the rocks. The fourth book explains the method of delimiting veins, and also describes the functions of the mining officials. The fifth book describes the digging of ore and the surveyor's art. The sixth book describes the miners' tools and machines. The seventh book is on the assaying of ore. The eighth book lays down the rules for the work of roasting, crushing, and washing the ore. The ninth book explains the methods of smelting ores. The tenth book instructs those who are studious of the metallic arts in the work of separating silver from gold, and lead from gold and silver. The eleventh book shows the way of separating silver from copper. The twelfth book gives us rules for manufacturing salt, soda, alum, vitriol, sulphur, bitumen, and glass.

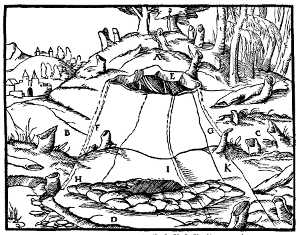

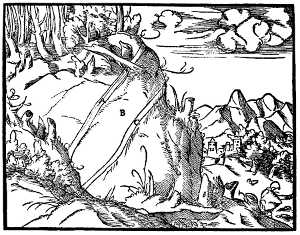

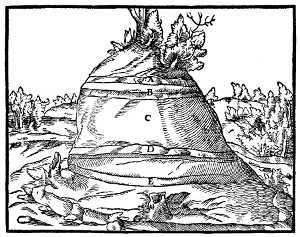

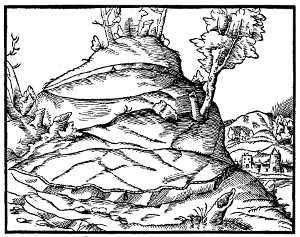

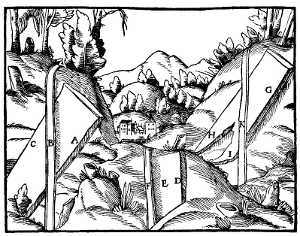

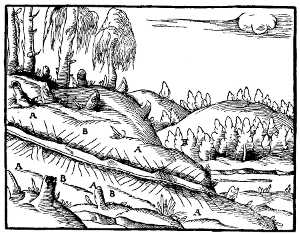

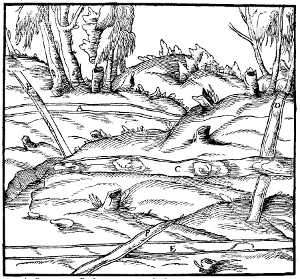

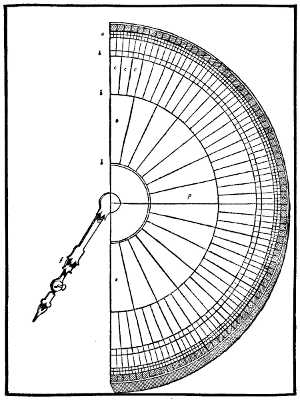

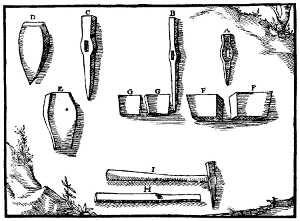

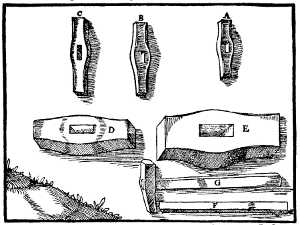

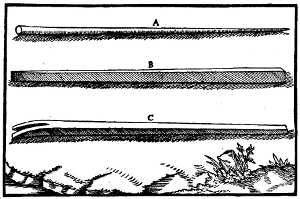

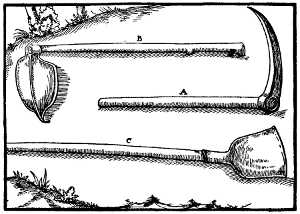

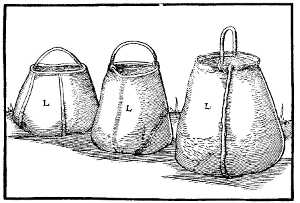

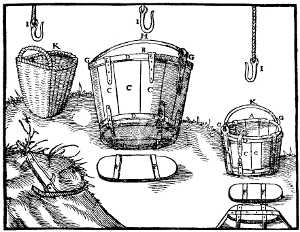

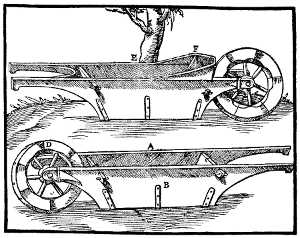

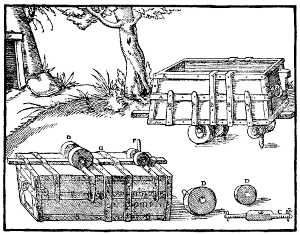

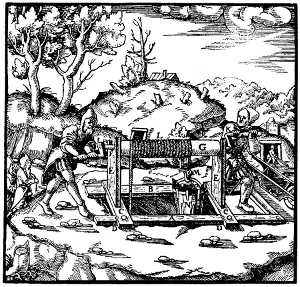

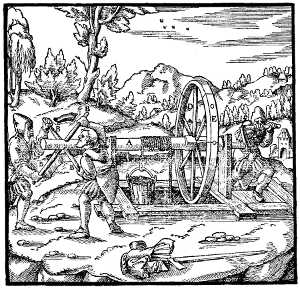

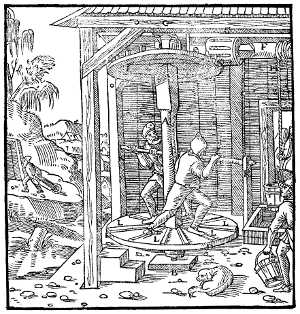

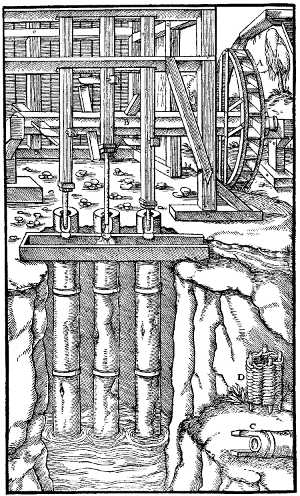

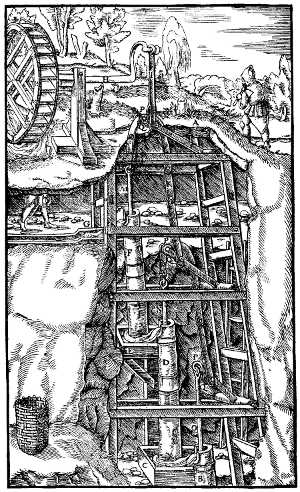

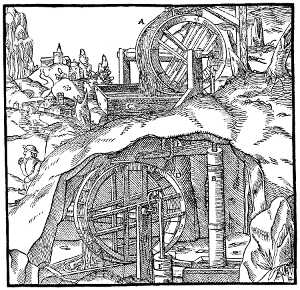

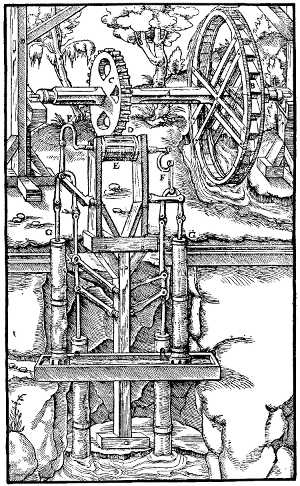

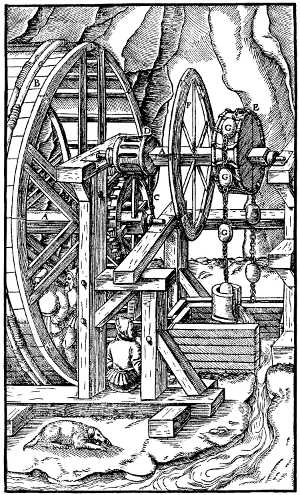

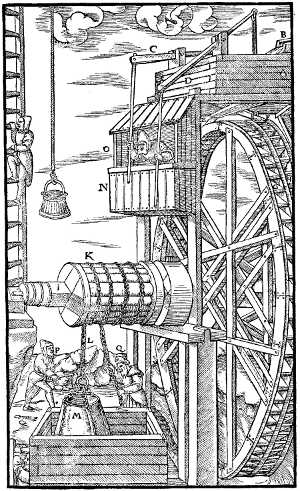

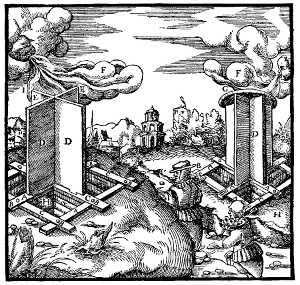

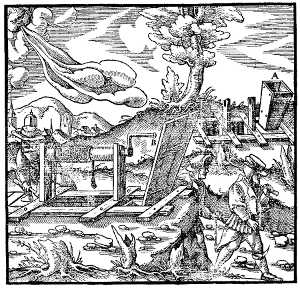

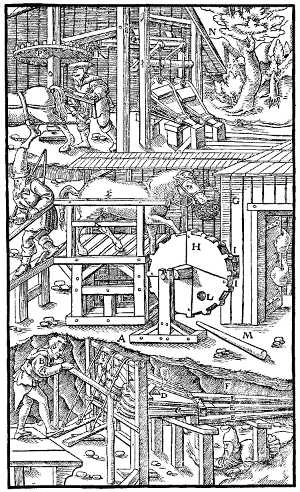

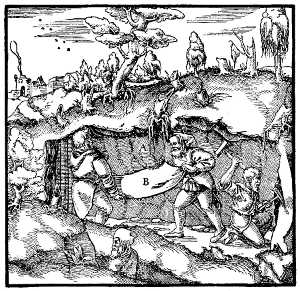

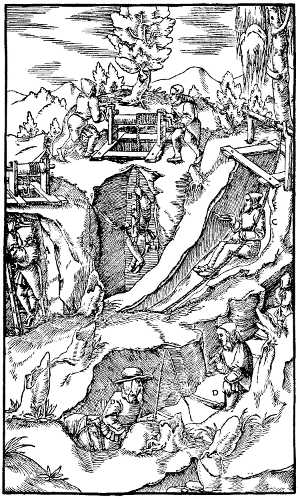

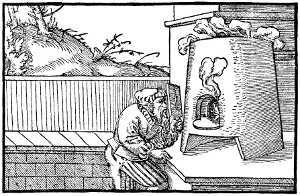

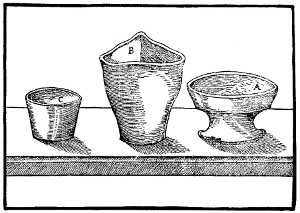

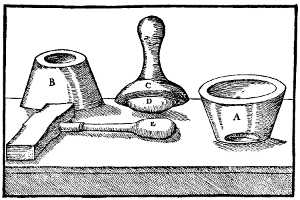

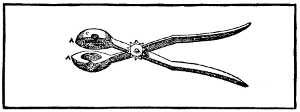

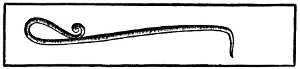

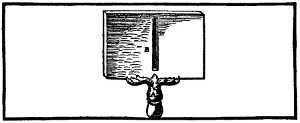

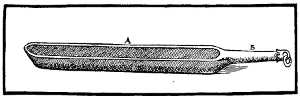

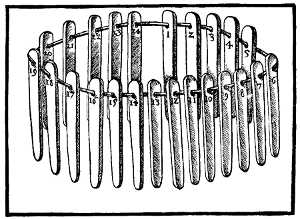

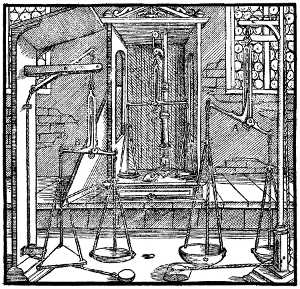

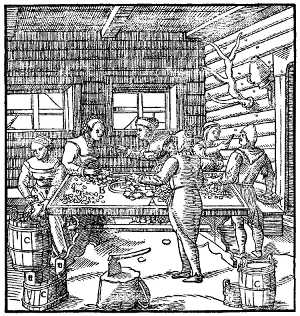

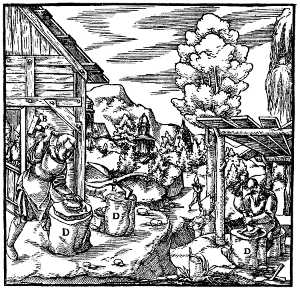

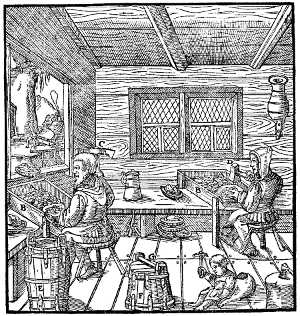

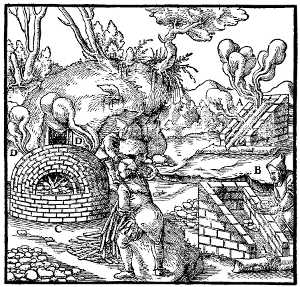

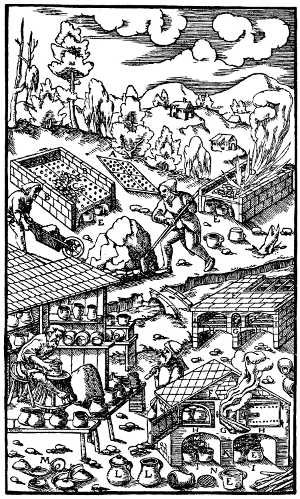

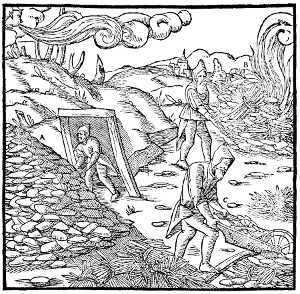

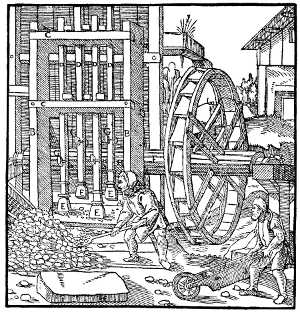

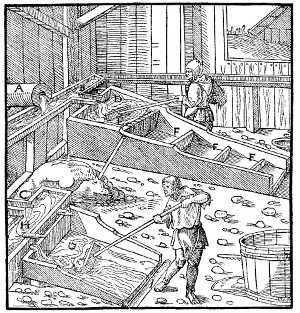

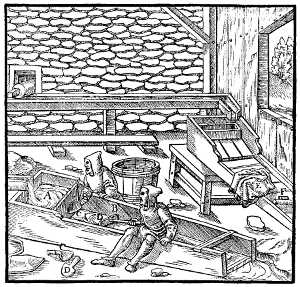

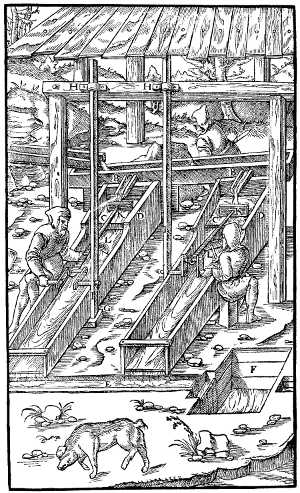

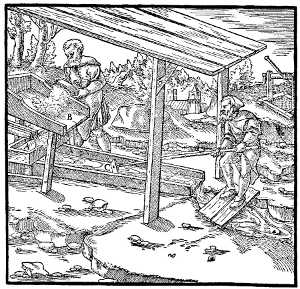

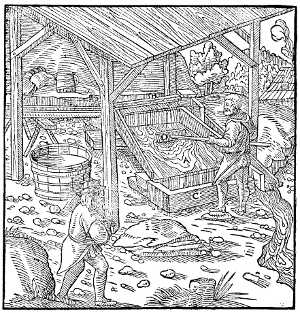

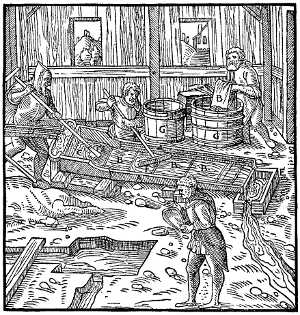

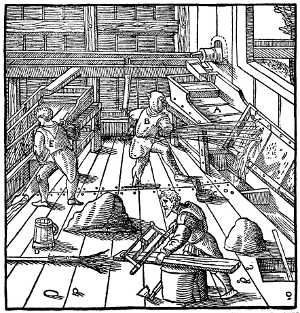

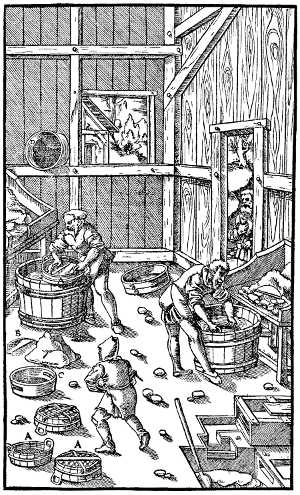

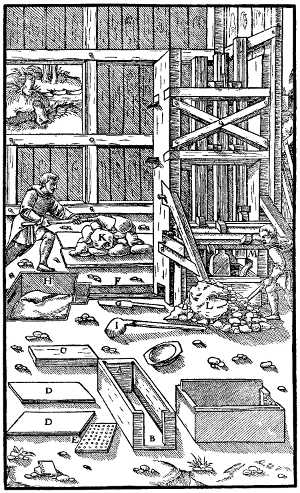

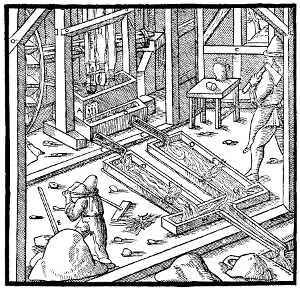

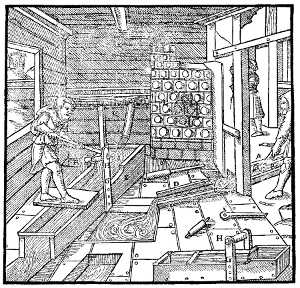

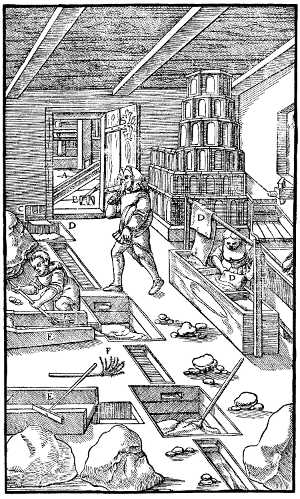

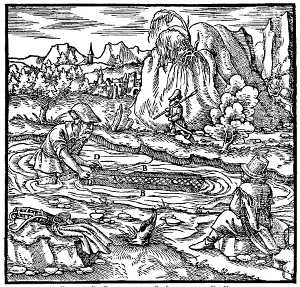

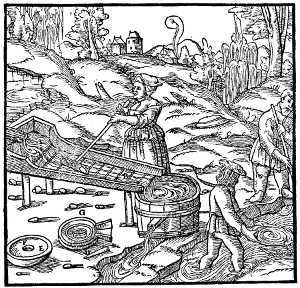

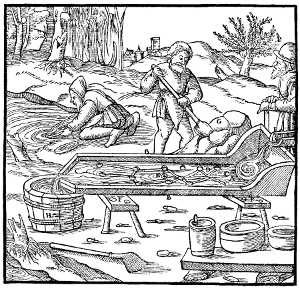

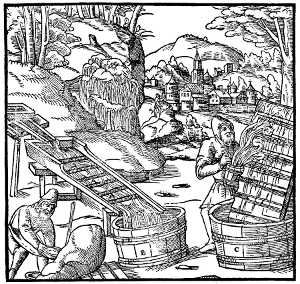

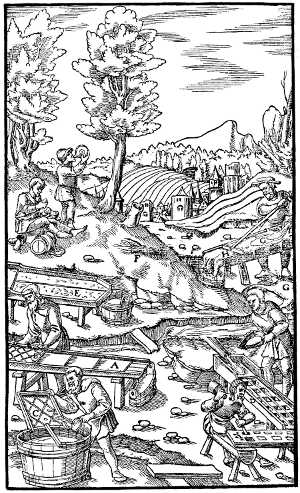

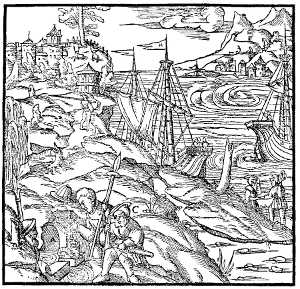

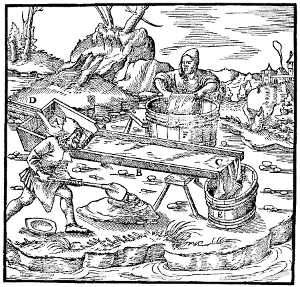

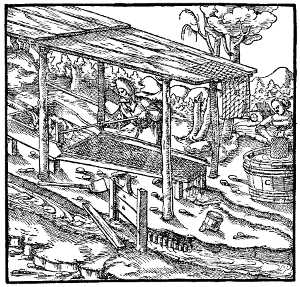

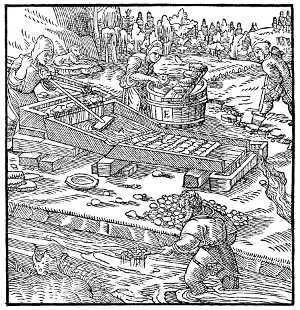

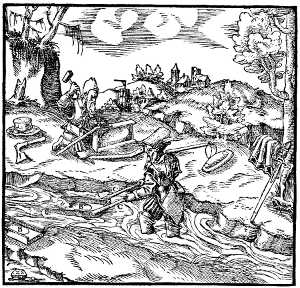

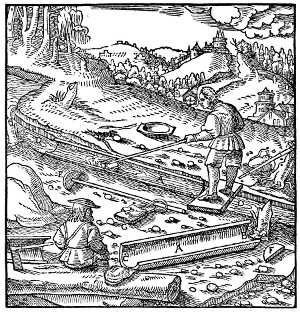

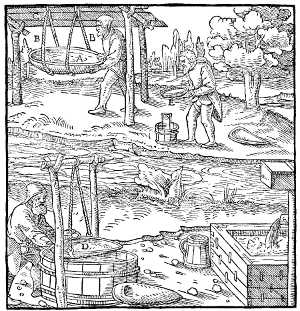

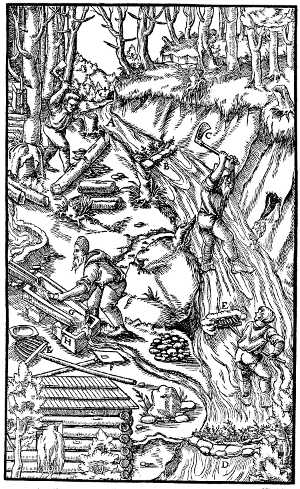

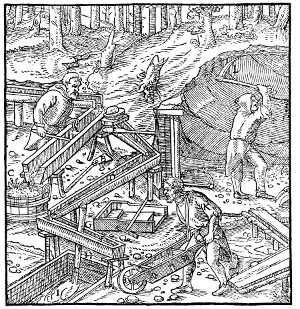

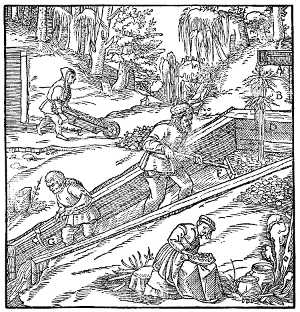

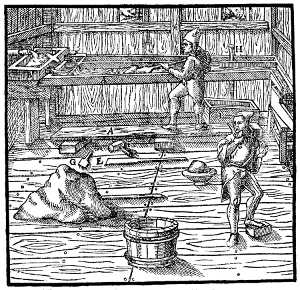

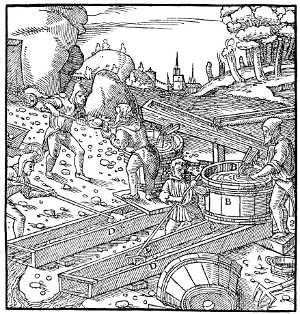

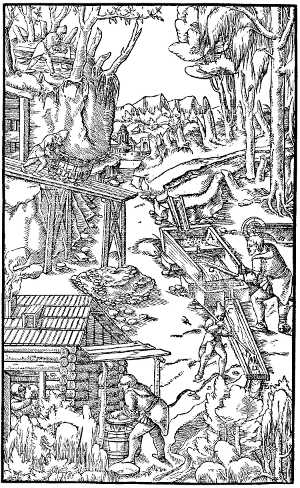

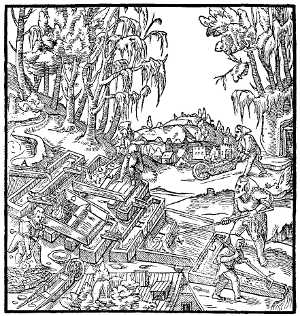

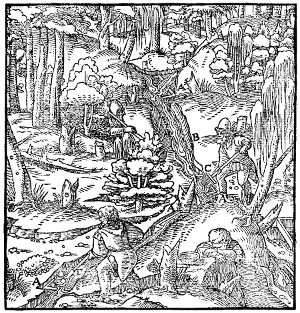

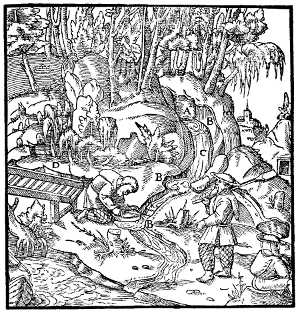

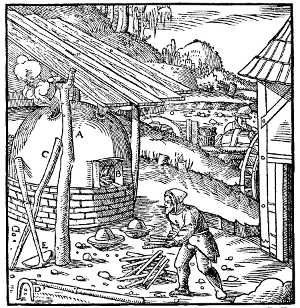

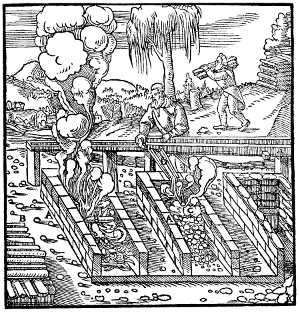

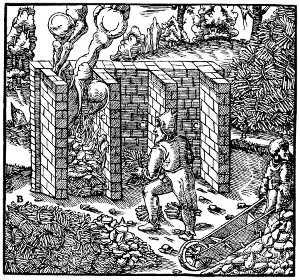

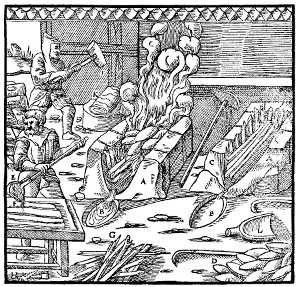

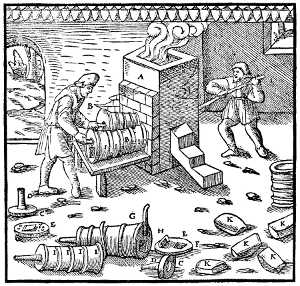

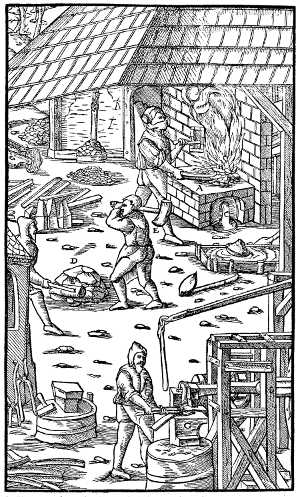

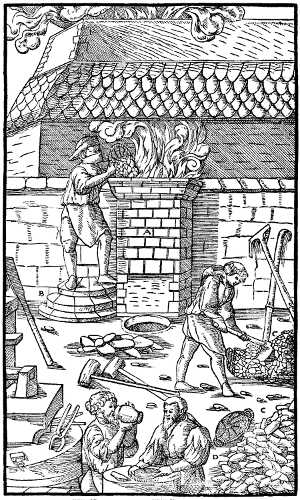

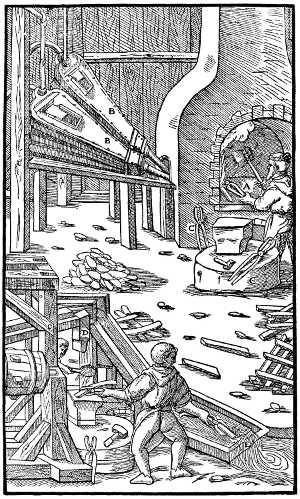

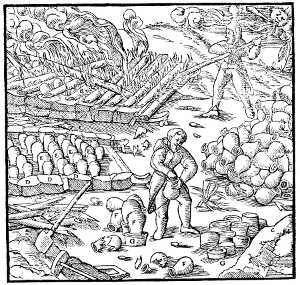

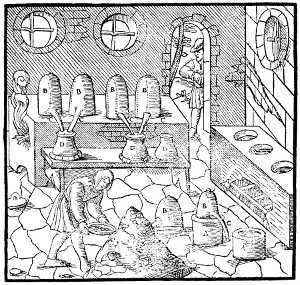

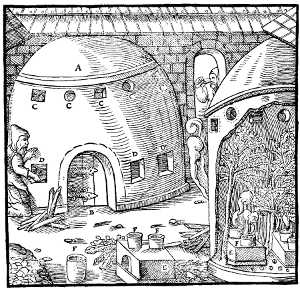

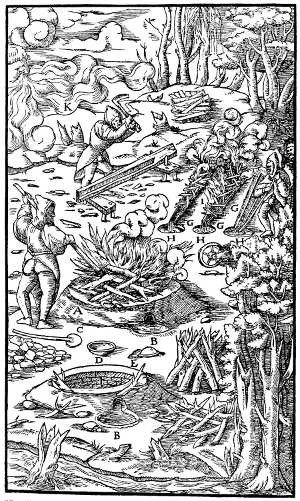

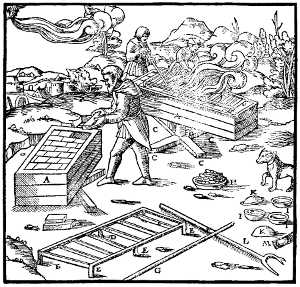

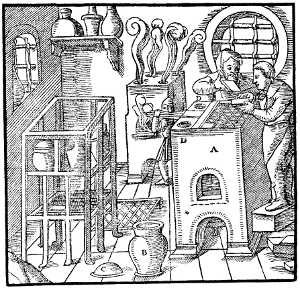

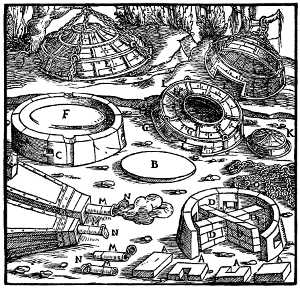

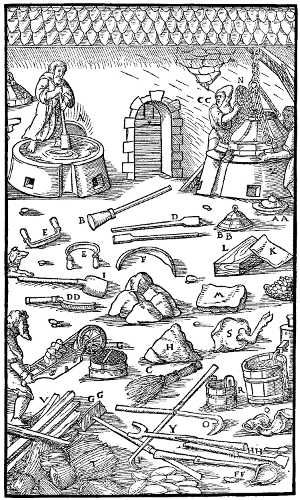

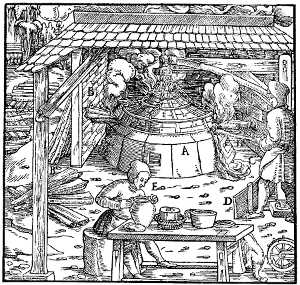

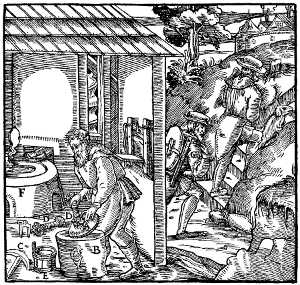

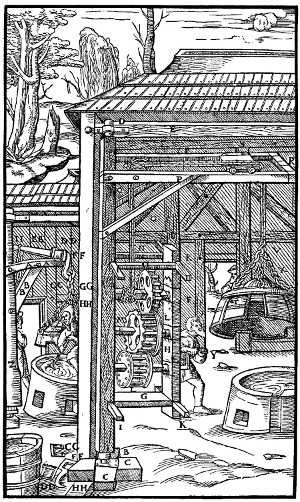

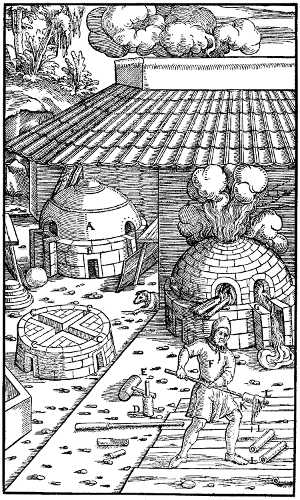

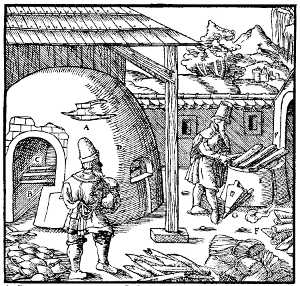

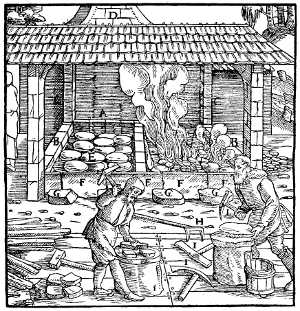

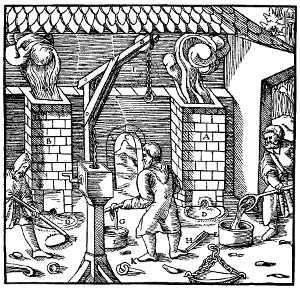

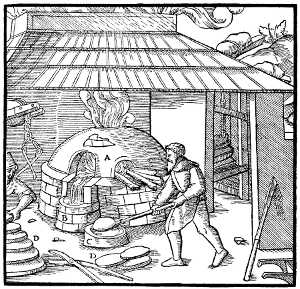

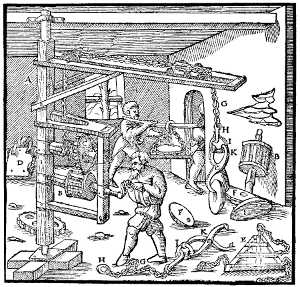

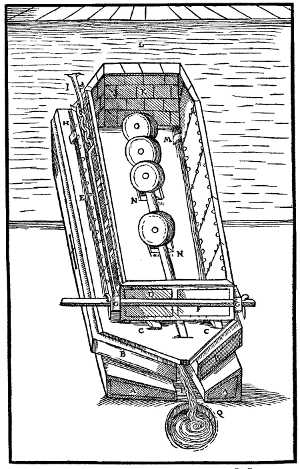

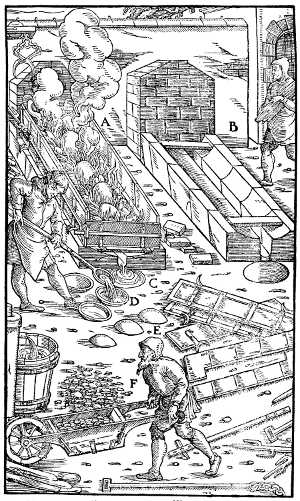

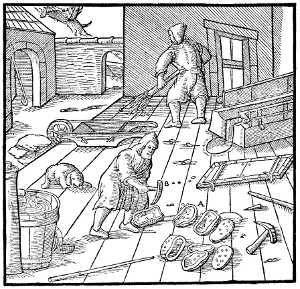

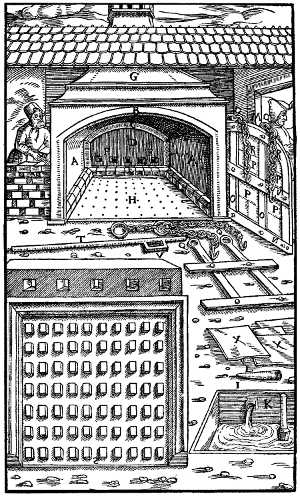

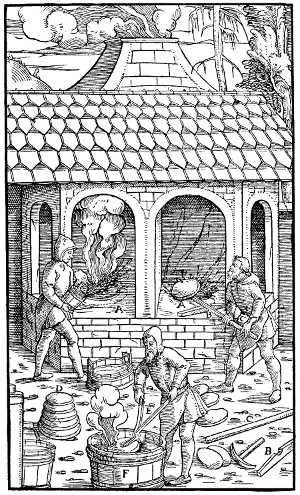

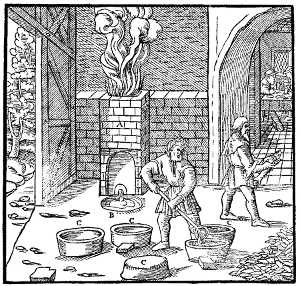

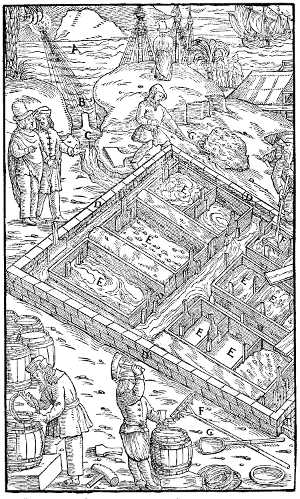

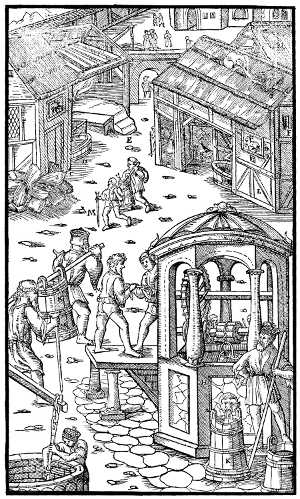

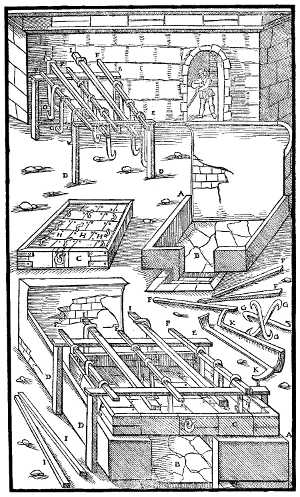

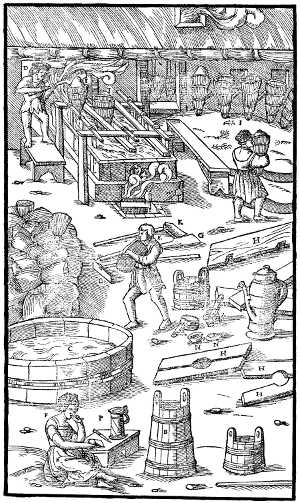

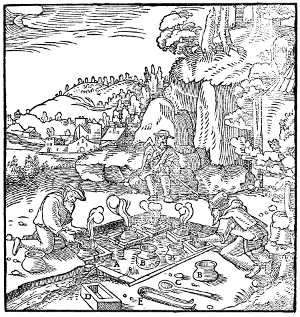

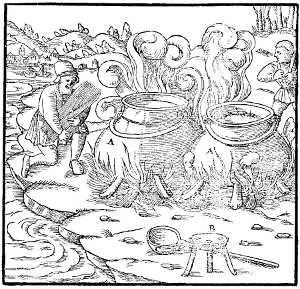

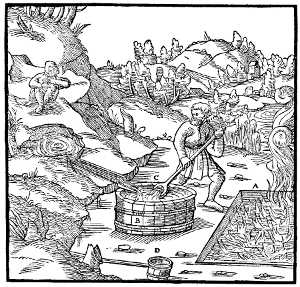

Although I have not fulfilled the task which I have undertaken, on account of the great magnitude of the subject, I have, at all events, endeavoured to fulfil it, for I have devoted much labour and care, and have even gone to some expense upon it; for with regard to the veins, tools, vessels, sluices, machines, and furnaces, I have not only described them, but have also hired illustrators to delineate their forms, lest descriptions which are conveyed by words should either not be understood by men of our own times, or should cause difficulty to posterity, in the same way as to us difficulty is often caused by many names which the Ancients (because such words were familiar to all of them) have handed down to us without any explanation.

I have omitted all those things which I have not myself seen, or have [Pg xxxi]not read or heard of from persons upon whom I can rely. That which I have neither seen, nor carefully considered after reading or hearing of, I have not written about. The same rule must be understood with regard to all my instruction, whether I enjoin things which ought to be done, or describe things which are usual, or condemn things which are done. Since the art of mining does not lend itself to elegant language, these books of mine are correspondingly lacking in refinement of style. The things dealt with in this art of metals sometimes lack names, either because they are new, or because, even if they are old, the record of the names by which they were formerly known has been lost. For this reason I have been forced by a necessity, for which I must be pardoned, to describe some of them by a number of words combined, and to distinguish others by new names,—to which latter class belong Ingestor, Discretor, Lotor, and Excoctor.[13] Other things, again, I have alluded to by old names, such as the Cisium; for when Nonius Marcellus wrote,[14] this was the name of a two-wheeled vehicle, but I have adopted it for a small vehicle which has only one wheel; and if anyone does not approve of these names, let him either find more appropriate ones for these things, or discover the words used in the writings of the Ancients.

These books, most illustrious Princes, are dedicated to you for many reasons, and, above all others, because metals have proved of the greatest value to you; for though your ancestors drew rich profits from the revenues of their vast and wealthy territories, and likewise from the taxes which were paid by the foreigners by way of toll and by the natives by way of tithes, yet they drew far richer profits from the mines. Because of the mines not a few towns have risen into eminence, such as Freiberg, Annaberg, Marienberg, Schneeberg, Geyer, and Altenberg, not to mention others. Nay, if I understand anything, greater wealth now lies hidden beneath the ground in the mountainous parts of your territory than is visible and apparent above ground. Farewell.

Chemnitz, Saxony,

December First, 1550.

[2] Lucius Junius Moderatus Columella was a Roman, a native of Cadiz, and lived during the 1st Century. He was the author of De Re Rustica in 12 books. It was first printed in 1472, and some fifteen or sixteen editions had been printed before Agricola's death.

[Pg xxvi][3] We give a short review of Pliny's Naturalis Historia in the Appendix B.

[4] This work is not extant, as Agricola duly notes later on. Strato succeeded Theophrastus as president of the Lyceum, 288 B.C.

[5] For note on Theophrastus see Appendix B.

[6] It appears that the poet Philo did write a work on mining which is not extant. So far as we know the only reference to this work is in Athenæus' (200 A.D.) Deipnosophistae. The passage as it appears in C. D. Yonge's Translation (Bonn's Library, London, 1854, Vol. II, Book VII, p. 506) is: "And there is a similar fish produced in the Red Sea which is called Stromateus; it has gold-coloured lines running along the whole of his body, as Philo tells us in his book on Mines." There is a fragment of a poem of Pherecrates, entitled "Miners," but it seems to have little to do with mining.

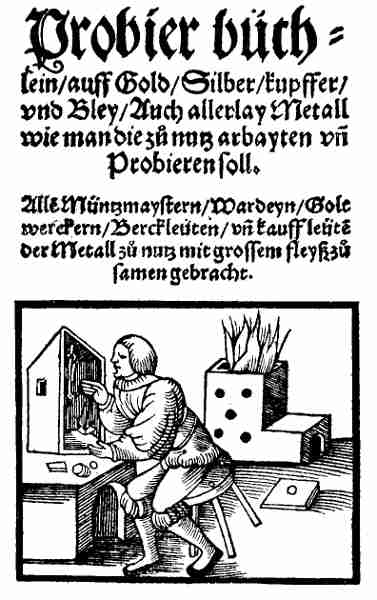

[7] The title given by Agricola De Materiae Metallicae et Metallorum Experimento is difficult to identify. It seems likely to be the little Probier Büchlein, numbers of which were published in German in the first half of the 16th Century. We discuss this work at some length in the Appendix B on Ancient Authors.

[8] Pandulfus, "the Englishman," is mentioned by various 15th and 16th Century writers, and in the preface of Mathias Farinator's Liber Moralitatum ... Rerum Naturalium, etc., printed in Augsburg, 1477, there is a list of books among which appears a reference to a work by Pandulfus on veins and minerals. We have not been able to find the book.

[Pg xxvii][9] Jacobi (Der Mineralog Georgius Agricola, Zwickau, 1881, p. 47) says: "Calbus Freibergius, so called by Agricola himself, is certainly no other than the Freiberg Doctor Rühlein von Kalbe; he was, according to Möller, a doctor and burgomaster at Freiberg at the end of the 15th and the beginning of the 16th Centuries.... The chronicler describes him as a fine mathematician, who helped to survey and design the mining towns of Annaberg in 1497 and Marienberg in 1521." We would call attention to the statement of Calbus' views, quoted at the end of Book III, De Re Metallica (p. 75), which are astonishingly similar to statements in the Nützlich Bergbüchlin, and leave little doubt that this "Calbus" was the author of that anonymous book on veins. For further discussion see Appendix B.

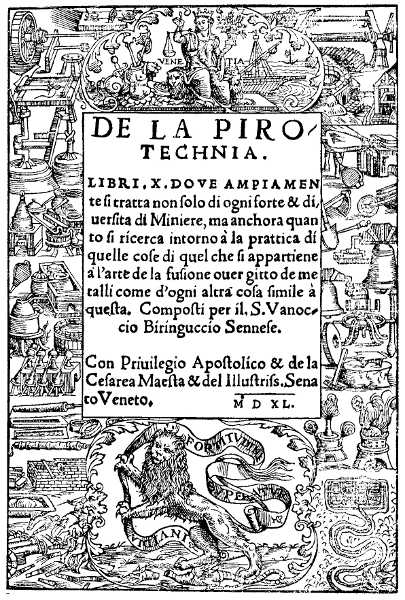

[10] For discussion of Biringuccio see Appendix B. The proper title is De La Pirotechnia (Venice, 1540).

[11] Hermolaus Barbarus, according to Watt (Bibliotheca Britannica, London, 1824), was a lecturer on Philosophy in Padua. He was born in 1454, died in 1493, and was the author of a number of works on medicine, natural history, etc., with commentaries on the older authors.

[12] The debt which humanity does owe to these self-styled philosophers must not be overlooked, for the science of Chemistry comes from three sources—Alchemy, Medicine and Metallurgy. However polluted the former of these may be, still the vast advance which it made by the discovery of the principal acids, alkalis, and the more common of their salts, should be constantly recognized. It is obviously impossible, within the space of a footnote, to [Pg xxviii]give anything but the most casual notes as to the personages here mentioned and their writings. Aside from the classics and religious works, the libraries of the Middle Ages teemed with more material on Alchemy than on any other one subject, and since that date a never-ending stream of historical, critical, and discursive volumes and tracts devoted to the old Alchemists and their writings has been poured upon the world. A collection recently sold in London, relating to Paracelsus alone, embraced over seven hundred volumes.

Of many of the Alchemists mentioned by Agricola little is really known, and no two critics agree as to the commonest details regarding many of them; in fact, an endless confusion springs from the negligent habit of the lesser Alchemists of attributing the authorship of their writings to more esteemed members of their own ilk, such as Hermes, Osthanes, etc., not to mention the palpable spuriousness of works under the names of the real philosophers, such as Aristotle, Plato, or Moses, and even of Jesus Christ. Knowledge of many of the authors mentioned by Agricola does not extend beyond the fact that the names mentioned are appended to various writings, in some instances to MSS yet unpublished. They may have been actual persons, or they may not. Agricola undoubtedly had perused such manuscripts and books in some leading library, as the quotation from Boerhaave given later shows. Shaw (A New Method of Chemistry, etc., London, 1753. Vol. I, p. 25) considers that the large number of such manuscripts in the European libraries at this time were composed or transcribed by monks and others living in Constantinople, Alexandria, and Athens, who fled westward before the Turkish invasion, bringing their works with them.

For purposes of this summary we group the names mentioned by Agricola, the first class being of those who are known only as names appended to MSS or not identifiable at all. Possibly a more devoted student of the history of Alchemy would assign fewer names to this department of oblivion. They are Maria the Jewess, Orus Chrysorichites, Chanes, Petasius, Pebichius, Theophilus, Callides, Veradianus, Rodianus, Canides, the maiden Taphnutia, Johannes, Augustinus, and Africanus. The last three are names so common as not to be possible of identification without more particulars, though Johannes may be the Johannes Rupeseissa (1375), an alchemist of some note. Many of these names can be found among the Bishops and Prelates of the early Christian Church, but we doubt if their owners would ever be identified with such indiscretions as open, avowed alchemy. The Theophilus mentioned might be the metal-working monk of the 12th Century, who is further discussed in Appendix B on Ancient Authors.

In the next group fall certain names such as Osthanes, Hermes, Zosimus, Agathodaemon, and Democritus, which have been the watchwords of authority to Alchemists of all ages. These certainly possessed the great secrets, either the philosopher's stone or the elixir. [Pg xxix]Hermes Trismegistos was a legendary Egyptian personage supposed to have flourished before 1,500 B.C., and by some considered to be a corruption of the god Thoth. He is supposed to have written a number of works, but those extant have been demonstrated to date not prior to the second Century; he is referred to by the later Greek Alchemists, and was believed to have possessed the secret of transmutation. Osthanes was also a very shadowy personage, and was considered by some Alchemists to have been an Egyptian prior to Hermes, by others to have been the teacher of Zoroaster. Pliny mentions a magician of this name who accompanied Xerxes' army. Later there are many others of this name, and the most probable explanation is that this was a favourite pseudonym for ancient magicians; there is a very old work, of no great interest, in MSS in Latin and Greek, in the Munich, Gotha, Vienna, and other libraries, by one of this name. Agathodaemon was still another shadowy character referred to by the older Alchemists. There are MSS in the Florence, Paris, Escurial, and Munich libraries bearing his name, but nothing tangible is known as to whether he was an actual man or if these writings are not of a much later period than claimed.

To the next group belong the Greek Alchemists, who flourished during the rise and decline of Alexandria, from 200 B.C. to 700 A.D., and we give them in order of their dates. Comerius was considered by his later fellow professionals to have been the teacher of the art to Cleopatra (1st Century B.C.), and a MSS with a title to that effect exists in the Bibliothèque Nationale at Paris. The celebrated Cleopatra seems to have stood very high in the estimation of the Alchemists; perhaps her doubtful character found a response among them; there are various works extant in MSS attributed to her, but nothing can be known as to their authenticity. Lucius Apulejus or Apuleius was born in Numidia about the 2nd Century; he was a Roman Platonic Philosopher, and was the author of a romance, "The Metamorphosis, or the Golden Ass." Synesius was a Greek, but of unknown period; there is a MSS treatise on the Philosopher's Stone in the library at Leyden under his name, and various printed works are attributed to him; he mentions "water of saltpetre," and has, therefore, been hazarded to be the earliest recorder of nitric acid. The work here referred to as "Heliodorus to Theodosius" was probably the MSS in the Libraries at Paris, Vienna, Munich, etc., under the title of "Heliodorus the Philosopher's Poem to the Emperor Theodosius the Great on the Mystic Art of the Philosophers, etc." His period would, therefore, be about the 4th Century. The Alexandrian Zosimus is more generally known as Zosimus the Panopolite, from Panopolis, an ancient town on the Nile; he flourished in the 5th Century, and belonged to the Alexandrian School of Alchemists; he should not be confused with the Roman historian of the same name and period. The following statement is by Boerhaave (Elementa Chemiae, Paris, 1724, Chap. I.):—"The name Chemistry written in Greek, or Chemia, is so ancient [Pg xxx]as perhaps to have been used in the antediluvian age. Of this opinion was Zosimus the Panopolite, whose Greek writings, though known as long as before the year 1550 to George Agricola, and afterwards perused ... by Jas. Scaliger and Olaus Borrichius, still remain unpublished in the King of France's library. In one of these, entitled, 'The Instruction of Zosimus the Panopolite and Philosopher, out of those written to Theosebia, etc....'" Olympiodorus was an Alexandrian of the 5th Century, whose writings were largely commentaries on Plato and Aristotle; he is sometimes accredited with being the first to describe white arsenic (arsenical oxide). The full title of the work styled "Stephanus to Heracleus Caesar," as published in Latin at Padua in 1573, was "Stephan of Alexandria, the Universal Philosopher and Master, his nine processes on the great art of making gold and silver, addressed to the Emperor Heraclius." He, therefore, if authentic, dates in the 7th Century.

To the next class belong those of the Middle Ages, which we give in order of date. The works attributed to Geber play such an important part in the history of Chemistry and Metallurgy that we discuss his book at length in Appendix B. Late criticism indicates that this work was not the production of an 8th Century Arab, but a compilation of some Latin scholar of the 12th or 13th Centuries. Arnold de Villa Nova, born about 1240, died in 1313, was celebrated as a physician, philosopher, and chemist; his first works were published in Lyons in 1504; many of them have apparently never been printed, for references may be found to some 18 different works. Raymond Lully, a Spaniard, born in 1235, who was a disciple of Arnold de Villa Nova, was stoned to death in Africa in 1315. There are extant over 100 works attributed to this author, although again the habit of disciples of writing under the master's name may be responsible for most of these. John Aurelio Augurello was an Italian Classicist, born in Rimini about 1453. The work referred to, Chrysopoeia et Gerontica is a poem on the art of making gold, etc., published in Venice, 1515, and re-published frequently thereafter; it is much quoted by Alchemists. With regard to Merlin, as satisfactory an account as any of this truly English magician may be found in Mark Twain's "Yankee at the Court of King Arthur." It is of some interest to note that Agricola omits from his list Avicenna (980-1037 A.D.), Roger Bacon (1214-1294), Albertus Magnus (1193-1280), Basil Valentine (end 15th century?), and Paracelsus, a contemporary of his own. In De Ortu et Causis he expends much thought on refutation of theories advanced by Avicenna and Albertus, but of the others we have found no mention, although their work is, from a chemical point of view, of considerable importance.

[14] Nonius Marcellus was a Roman grammarian of the 4th Century B.C. His extant treatise is entitled, De Compendiosa Doctrina per Litteras ad Filium.

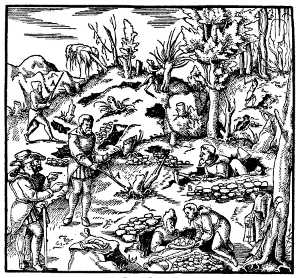

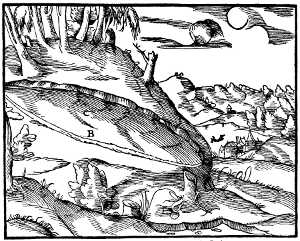

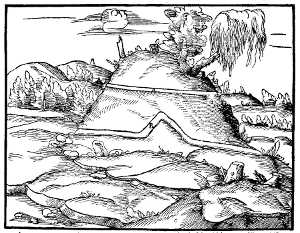

any persons hold the opinion that the metal industries are fortuitous and that the occupation is one of sordid toil, and altogether a kind of business requiring not so much skill as labour. But as for myself, when I reflect carefully upon its special points one by one, it appears to be far otherwise. For a miner must have the greatest skill in his work, that he may know first of all what mountain or hill, what valley or plain, can be prospected most profitably, or what he should leave alone; moreover, he must understand the veins, stringers[1] and seams in the rocks[2]. Then he must be thoroughly familiar with the many and varied species of earths, juices[3], gems, stones, marbles, rocks, metals, and compounds[4]. He must also have a [Pg 2]complete knowledge of the method of making all underground works. Lastly, there are the various systems of assaying[5] substances and of preparing them for smelting; and here again there are many altogether diverse methods. For there is one method for gold and silver, another for copper, another for quicksilver, another for iron, another for lead, and [Pg 3]even tin and bismuth[6] are treated differently from lead. Although the evaporation of juices is an art apparently quite distinct from metallurgy, yet they ought not to be considered separately, inasmuch as these juices are also often dug out of the ground solidified, or they are produced from certain kinds of earth and stones which the miners dig up, and some of the juices are not themselves devoid of metals. Again, their treatment is not simple, since there is one method for common salt, another for soda[7], another for alum, another for vitriol[8], another for sulphur, and another for bitumen.

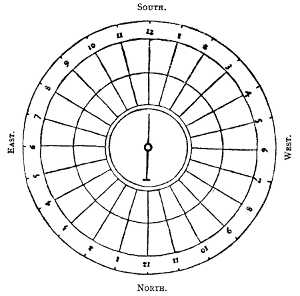

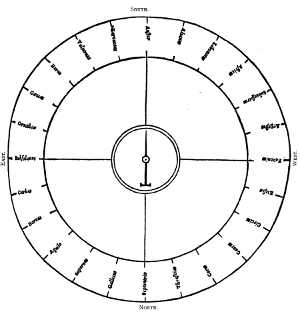

Furthermore, there are many arts and sciences of which a miner should not be ignorant. First there is Philosophy, that he may discern the origin, cause, and nature of subterranean things; for then he will be able to dig out the veins easily and advantageously, and to obtain more abundant results from his mining. Secondly, there is Medicine, that he may be able to look after his diggers and other workmen, that they do not meet with those [Pg 4]diseases to which they are more liable than workmen in other occupations, or if they do meet with them, that he himself may be able to heal them or may see that the doctors do so. Thirdly follows Astronomy, that he may know the divisions of the heavens and from them judge the direction of the veins. Fourthly, there is the science of Surveying that he may be able to estimate how deep a shaft should be sunk to reach the tunnel which is being driven to it, and to determine the limits and boundaries in these workings, especially in depth. Fifthly, his knowledge of Arithmetical Science should be such that he may calculate the cost to be incurred in the machinery and the working of the mine. Sixthly, his learning must comprise Architecture, that he himself may construct the various machines and timber work required underground, or that he may be able to explain the method of the construction to others. Next, he must have knowledge of Drawing, that he can draw plans of his machinery. Lastly, there is the Law, especially that dealing with metals, that he may claim his own rights, that he may undertake the duty of giving others his opinion on legal matters, that he may not take another man's property and so make trouble for himself, and that he may fulfil his obligations to others according to the law.

It is therefore necessary that those who take an interest in the methods and precepts of mining and metallurgy should read these and others of our books studiously and diligently; or on every point they should consult expert mining people, though they will discover few who are skilled in the whole art. As a rule one man understands only the methods of mining, another possesses the knowledge of washing[9], another is experienced in the art of smelting, another has a knowledge of measuring the hidden parts of the earth, another is skilful in the art of making machines, and finally, another is learned in mining law. But as for us, though we may not have perfected the whole art of the discovery and preparation of metals, at least we can be of great assistance to persons studious in its acquisition.

But let us now approach the subject we have undertaken. Since there has always been the greatest disagreement amongst men concerning metals and mining, some praising, others utterly condemning them, therefore I have decided that before imparting my instruction, I should carefully weigh the facts with a view to discovering the truth in this matter.