Title: Leather for Libraries

Author: E. Wyndham Hulme

Cyril Davenport

J. Gordon Parker

A. Seymour-Jones

F. J. Williamson

Release date: March 21, 2016 [eBook #51522]

Most recently updated: October 23, 2024

Language: English

Credits: Produced by Chris Curnow, Chris Jordan and the Online

Distributed Proofreading Team at http://www.pgdp.net (This

file was produced from images generously made available

by The Internet Archive)

BY

E. WYNDHAM HULME, J. GORDON PARKER,

A. SEYMOUR-JONES, CYRIL DAVENPORT,

AND

F. J. WILLIAMSON

LONDON:

Published for the Sound Leather Committee of the

Library Association

by

THE LIBRARY SUPPLY Co.,

Bridge House, 181, Queen Victoria Street, E.C.

1905.

LIBRARY ASSOCIATION.

CONSTITUTION OF THE SOUND LEATHER COMMITTEE.

Cyril Davenport, British Museum Library.

J. P. Edmond, Signet Library, Edinburgh.

Dr. J. Gordon Parker, London Leather Industries Laboratory, Bermondsey.

E. Wyndham Hulme, Patent Office Library. (Hon. Secretary.)

| CHAPTER I. | |

| Page | |

| History of Sumach Tanning in England, Degradation of the Manufacture of Leather, and History of the Reform Movement. By E. Wyndham Hulme | 5 |

| CHAPTER II. | |

| The Causes of Decay in Bookbinding Leathers. By J. Gordon Parker | 15 |

| CHAPTER III. | |

| Provenance, Characteristics, and Values of Modern Bookbinding Leathers. By A. Seymour-Jones | 29 |

| CHAPTER IV. | |

| The Repairing and Binding of Books for Public Libraries. By Cyril Davenport | 39 |

| CHAPTER V. | |

| Specification for the Fittings of a Small Bindery. By F. J. Williamson | 51 |

| Index | 55 |

The Bancroft Library

University of California · Berkeley

The Roger Levenson

Memorial Fund

CHAPTER I.

The section of the leather trade to which this Handbook relates is that concerned in the manufacture of light leathers tanned with a pale tannage preparatory to being dyed. Bark and most other vegetable tanning substances leave a colour on the skin which cannot be removed without detriment to the durability of the leather; the retention of the colour, however, detracts from the purity of the final colour imparted by the dye. The reputation in the past of the sumach-tanned Spanish leather was founded upon this peculiar property of sumach of leaving the skin white, and on this point the wisdom of the ancients has been justified by the results of an exhaustive series of experiments conducted by the Society of Arts’ Committee, which have given to sumach the first place in the list of tannages for light leathers.

The date of the introduction of sumach tanning into England may, with some show of probability, be assigned to the year 1565, when a seven years’ monopoly patent was granted to two strangers, Roger Heuxtenbury and Bartholomew Verberick, for the manufacture of “Spanish or beyond sea leather,” on the condition that the patentees should employ one native apprentice for every foreigner in their service. This stipulation indicates that the industry was a new one. Following the custom of the times, the supervision of the industry was entrusted to the “Wardens of the Company of Leathersellers in London.” Additional evidence of the use of sumach at this period is afforded by another patent to a Spanish Jew, Roderigo Lopez, one of Elizabeth[8]’s physicians. By way of settling her doctor’s bills the Queen granted to Lopez, in 1584, an exclusive licence to import sumach and aniseed for ten years. Besides attending the Queen in his professional capacity, Lopez was called upon to act as interpreter to the Portuguese pretender, Don Antonio, on his visit to this island. As the result of some misunderstanding with Antonio, Lopez was induced to join a conspiracy nominally aimed against the life of Antonio, but actually directed against the Queen, and in 1594 Lopez expiated his crimes at Tyburn. Those who are curious in such matters will be interested to trace in the “Merchant of Venice” the re-appearance of our sumach merchant as Shylock, while the name of Antonio is boldly retained by Shakespeare for his hero (Cf. S. Lee, “The Original of Shylock,” in the Gentleman’s Magazine, 1880). After the arrest of Lopez, his grant was continued to R. Alexander and R. Mompesson (Patent Roll, 36 Eliz., p. 11). In the Charter of the Leathersellers’ Company, dated 1604, “Spanish leather and other leathers dressed or wrought in sumach or bark” are mentioned. In 1660 the duty granted upon imported sumach was fixed at 13s. 4d. per cwt. of 112 lbs., and on dried myrobalans at 1s. 3d. per lb., thus disproving the statement of Prof. Thorold Rogers in his “History of Prices” (Vol. 5, p. 414), that oak bark was the only tanning material used in England at this period. The earliest description known to the writer of the process of sumaching by sewing up the skins into bottles and allowing the fluid extract to penetrate the fibre by pressure, is to be found in 1754 in the “Dictionary of Arts and Science” (Vol. 3, article “Morocco”).

The first step in the degradation of the manufacture of light leathers, though it at first affected the heavy leathers only, was the introduction of the use of sulphuric acid in 1768 by Dr. McBride of Dublin (Phil. Trans., 1778). By substituting a vitriolic liquor for the vegetable acids obtained by fermenting bran, rye, or other cereals, Dr. McBride claimed three advantages:[9] (1) Absolute control over the degree of acidity of the liquor, whereas organic souring was troublesome and uncertain; (2) that the skins were “plumped” better by the acid, and that the danger of injury to skins (by bacterial action) was avoided; (3) that the process of tanning was materially shortened. At all events, the Doctor succeeded in convincing first the Dublin tanners, and shortly afterwards their Bermondsey rivals, of the superiority of his methods, which, as already stated, were intended for heavy leathers only (Encyclopædia Britannica, 1797, article “Tanning”).

Having once established its footing in the tanyard the use of sulphuric acid was soon further extended. With the introduction of aniline dyestuffs about 1870 sulphuric acid came into universal use as a means of clearing the skin before entering the dyebath. The effect of the introduction of the coal-tar colours was to revolutionise the dyeing of leather. Under the old régime of the vegetable dyestuffs the few standard shades of red, blue, olive, yellow, and black were obtained on moroccos mordanted with alum, while bark-tanned calf and sheep skins were, as a rule, left in their natural browns and ornamented by sprinkling or marbling. The wide range of colours offered by the new dyestuffs fascinated the public, which accepted the new leathers without question as to their durability. Librarians began to insist upon accuracy and uniformity of shade, regardless of the methods by which these results were obtained. Yet, apart from the question of durability, it is clear that brilliancy of colour has been purchased at too high a price. Under the old system of dyeing a thin superficial layer of colour was laid over the natural white of the skin, thereby obtaining a variety and depth of colour which is in striking contrast to the dead uniformity of the colours of modern acid-bitten leathers. Hence the reform of the manufacture of the light leathers is supported by æsthetic as well as by practical considerations.

Passing from the domain of chemistry to that of mechanics, the Committee of the Society of Arts has emphasized the need of a return to sounder and less ruinous methods of dealing with leather; but their recommendations are so clearly set out in their Report that it is proposed here to touch upon one point only, viz., the artificial graining of leather. The Committee remark that, whereas many examples of sound sheepskin, dating from the 15th century to the early part of the 19th century, had been brought to their notice, “since about 1860 sheepskin as sheepskin is hardly to be found.” Now, the decoration of leather by the impression of patterns by mechanical pressure had long been known, the lozenge pattern of early russia leather having been effected in the 18th century by means of engraved steel cylinders. But in 1851 it occurred to an ingenious mechanic that, by means of the electroplate process, an exact reproduction of the grain of the higher-priced skins might be communicated to sheepskin or other inferior leather whereby the selling value of the latter would be considerably enhanced (Cf. Bernard’s Patent Specification 13,808 of 1851, and a modification of the same process in No. 2,391 of 1855). From this date, therefore, sheepskin disappears from view only to reappear as imitation morocco, pigskin, or other higher-priced leather. So perfectly does the counterfeit skin imitate the original on the bound volume that the two can only be distinguished with certainty by microscopic examination. Librarians, therefore, must bear in mind that a familiarity with the natural characteristics of the ordinary binding leathers is no safe guide to the character of the leather of a binding. The utmost that can be said is that the leather is either genuine or else a remarkably good counterfeit, a conclusion which, it is hardly necessary to say, is not one of great value in practice.

As might have been supposed, the rapid decay of leather bindings in the 19th century, resulting from a combination of the above malpractices, with the attendant[11] evils of heavy outlay upon rebinding, cropped margins, and ill-matched sets upon the shelves, from time to time attracted the attention of booklovers and bookbinders; but their efforts to determine the causes of the deterioration and to find a remedy have until recently met with very little success. In 1842 the subject was investigated by Professors Faraday, Brande, and others on behalf of the Athenæum Club. This committee is largely responsible for the “sulphur in gas” theory—a theory which was never wholly true, even at a period when the percentage of sulphur in coal gas was much higher than at present (Cf. Journal of the Society of Arts, 1850-59, p. 215), and which now has ceased to have any practical bearing upon the matter. It should be noted that, in 1851, Crace Calvert, the well-known Manchester chemist, came to a different conclusion. After pointing out that decay in leather was observable in libraries, such as the Chetham Library, in which gas had never been used, he stated that the presence of sulphuric acid in leather bindings was attributable to one or more of three causes: (a) to the pollution of the atmosphere by consumption of coal in the Manchester factories; (b) to the action of gas fumes in unventilated rooms; (c) to the use of sulphuric acid by the tanners; and he further expressed his opinion that the seat of the disease would be found in irregularities in the processes of tanning—in other words, that the disease was aggravated rather than originated by these first two causes (Cf. Trans. Society of Arts, Vol. 51, pp. 120-22). Calvert’s views, however, met with very little support. In 1877, at the Conference of Librarians in London, a proposal was made that a committee of librarians and chemists should deal with the matter, but no effect was given to the proposal. Ten years later a series of experiments on the action of gas fumes and heat was undertaken on behalf of the Birmingham Library by Mr. C. T. Woodward (Library Chronicle, 1887, pp. 25-29). Strips of leather exposed for 1,000 hours to the action of gas fumes, at temperatures of 130°[12] and 140° Fahrenheit, showed a mean absorption of sulphuric acid of 1·78 per cent., accompanied by a marked reduction in their stretching capacity and breaking strain. The experiments on the action of heat alone were regarded as inconclusive. Mr. Woodward suggested that the Library Association should undertake the testing of leathers, and that librarians should thereafter employ only leather of a given standard; but once more nothing was done. In the meantime the reputation of leather as a binding material continued to dwindle; one leather after another was tried, found wanting, and excluded from library practice, while various leather substitutes—buckram, art linen, and imitation leathers, gradually took its place. It is due to the efforts of Dr. Parker and Prof. Procter between 1898 and 1900 that the real facts of the case have been brought to light. In the latter years an agitation in favour of standard leather was set on foot by Lord Cobham, Mr. Cockerell, Mr. Davenport, and others, which resulted in the appointment by the Society of Arts of a Committee on Leathers for Bookbinding, the cost of which was met by a grant from the Leathersellers’ Company.

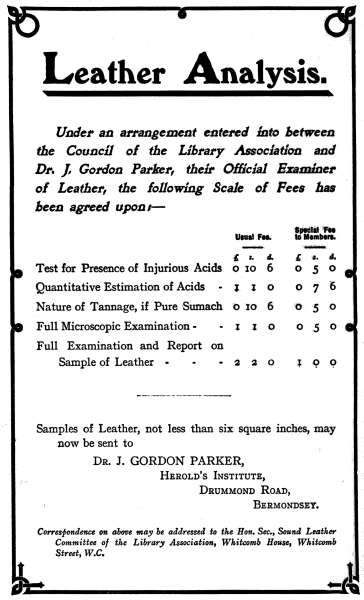

Upon the publication of the first report of the above Committee in 1901 the subject was taken up by the Council of the Library Association, and after several papers had been read at the monthly meetings in London and elsewhere, a Committee was appointed to ascertain how far Members of the Association were prepared to accept a common standard for binding leathers. For this purpose in March 1904, close upon 1,000 circulars were addressed to the libraries of the United Kingdom asking for a statement of their views upon the following proposals, amongst others, viz.: (a) that the Council should appoint an official analyst; (b) that they should publish a handbook giving to members of the Association such information as would enable them to secure sound leather at a reasonable price. The circular meeting with a favourable reception, the Council invited Dr. Parker to draw up a scale of[13] fees for the analysis of leathers, and the scale having been duly approved, Dr. Parker was at once appointed analyst to the Association.

Since the appointment of the Committee abundant evidence has been forthcoming that at last the reform of light leathers for bookbinding and upholstery is now in sight. The efforts of the Committee have been warmly seconded by the Press. In the recently concluded Government binding contracts a clause has been inserted enabling any department to obtain standard leather and rendering the contractor liable to heavy penalties for infringement of the conditions of this clause; yet the price paid for bindings in this leather is only fractionally increased. From the outset the Committee have been assured of the support of the leading firms of leather manufacturers, who have recognised that, if leather is to regain the ground which has been lost, it must be by the adoption of a common standard of manufacture and by the introduction of honest trade descriptions in the retail trade.

Hence where the provenance of the leather is declared and the method of its manufacture supported by a written guarantee from the leather manufacturer, the need for periodical analysis of samples is less urgent. But where the bookbinder is unwilling or unable to state the provenance of his leathers recourse to chemical analysis is the only safeguard. The librarian on his side will materially assist the binder by limiting his demand to leathers of a few standard shades and by abstaining from insisting upon accurate matching to pattern. If the piecing, panelling and lettering of serials is kept uniform, a want of uniformity in the shade of leather is not of much practical moment. In the meantime the librarian should keep a vigilant watch for the following symptoms of deterioration:—

(a) General shabbiness and tenderness of leather, especially at parts where the leather is strained over the cords on the back or edges of the boards. Probable cause: Sulphuric acid.

(b) Red rot in morocco. On friction the leather turns to a red powder. Probable cause: A Persian or East Indian half-bred sheepskin has been supplied in place of goat.

(c) Withering of pigskin accompanied by discoloration. Probable cause: Over “pulling down” of the skin in the “puering” process. If the pigskin has been dyed in a bright shade, acid also is present.

(d) Deterioration and discoloration of smooth and light-coloured calfskins, especially law calf. Probable cause: Use of oxalic acid by the bookbinder to remove grease marks, &c.

CHAPTER II.

Why do modern leather bindings decay? Is it possible to obtain a leather for bookbinding purposes as good and as durable as the leather produced from the 16th to 18th century? These are the two problems which the Committee on Bookbinding Leather appointed by the Society of Arts set themselves to investigate. Fortunately we are able to solve both problems.

In the olden days all skins were tanned with a liquor made from either oak bark or sumach, and in some cases a mixture of the two. The skins used by the tanner were usually obtained direct from the butchers. After soaking and cleansing they were then limed for a period sufficiently long to loosen the hair. After the removal of the hair and superfluous flesh and fat, the skins were washed in several changes of fresh soft water to remove the excess of lime, the process being assisted by working the skins over on a beam with a blunt knife. When in suitable condition they were brought into sour, old tan liquors. There was no hurry, the skins being slowly tanned in weak infusions, and when the process was complete, the leather was simply washed free from superfluous tan, dyed with wood or other vegetable dyes, rinsed free from excess of dye-stuff, and dried out. The leather was afterwards softened by stretching, and polished or glazed by brushing the skin over with oil, soap, beeswax, or a solution of some moss. Such leather lacked the high finish, the regular colour, the bright shades of modern leather, but it lasted fifty or one hundred years with hard wear, and, under favourable conditions, appears to be almost imperishable.

The finish, or general appearance, of leather continued to improve up to about 1850, but after that date some of the bindings examined showed signs of rapid deterioration in quality. This deterioration increased on bindings subsequent to 1870, and probably 75 per cent. of the leather used for bookbinding during the last twenty years either has already decayed or will do so within a comparatively short time.

Now to deal with the answer to the first question, Why do modern leather bindings decay? The chief causes are as follows:—

1. The introduction of tanning materials other than oak and sumach, stronger in tanning, and more rapid in their action. Many of these tanning materials are unstable, and the leather produced disintegrates on exposure to light and air.

2. The use of dried and cured skins of variable soundness imported from abroad. Goat, calf, and sheep skins are imported into this country from all over the world; some are simply dried in the sun, some salted, whilst others are cured with various ingredients.

3. The use of infusions of acids and other bleaching agents to produce bright and even shades of colour.

4. The use of sulphuric or other mineral acids for the purpose of developing the depth of colour during the process of dyeing.

5. The shaving and splitting of skin for producing an even substance.

6. Printing and embossing grains upon leather, together with other methods of finishing now in common use.

7. The stripping, scouring, souring, and re-tanning of East India leathers (Persians).

8. The removal of the natural grease or nourishment of the skin.

These eight causes, although by no means exhaustive, are, however, the chief factors in the deterioration of modern leather; and in as few words as possible I will explain the reason of their introduction and effect.

As the industry advanced there were found in different parts of the world tanning materials other than oak and sumach, some of which were two, three, or five times as rich in tannin as oak, thus making infusions of greater strength, and consequently of quicker action, with the result that leather which formerly required from three to six months to tan was turned out in almost as many days, or, at the most, in as many weeks. It was not realised, however, that these different tanning materials contained tannins of different qualities, capable of producing quite a different leather to that produced by means of oak or sumach. The experts who spent months testing and investigating this question came to the unanimous conclusion that the speed of tannage or the strength of the tanning liquor had very little to do with the wearing qualities of the leather produced, but found that some of these new materials contained tannins of a different chemical nature from that of sumach, and that they produced leather of an unstable character, some of the leathers undergoing change in a few hours on exposure to strong light and air. On the other hand, some of the new tanning materials produced permanent leathers practically equal to sumach. Those tanning materials, therefore, which contained tannins of the catechol series, including the tannins of hemlock, larch, quebracho, mangrove, gambier, and turwar, were condemned, as all these materials produce a leather which on exposure to light and air turns first a red shade of colour and afterwards develops what is now well known by bookbinders and librarians as the red decay, where the leather crumbles off on application of friction. On the other hand, tanning materials of the pyrogallol class, such as sumach, galls, divi-divi, myrobalans, oak, and chesnut, produce a leather which is practically unaffected by light or air. Further,[20] it was found in every case where authentic bindings dating from the 13th century onwards were examined the tanning material used was one of this pyrogallol series. On the other hand, leathers which showed the red decay were in every case found either to have been tanned with tanning materials of the catechol series, or were rotted with acid.

The second cause of trouble is the manufacture of leather from skins from distant lands which have been improperly or insufficiently preserved for export. It often happens that the fibres have partly perished before the tanner receives the skins, the resulting leather is therefore poor, spongy, and partially perished, making thin leather, which sometimes, on account of its thinness, will cut up apparently economically for the binder, but not economically for the librarian or the owner of books, as the leather cannot possibly be as good or have as long life as leather manufactured from a sound skin.

Bright even shades and light fancy colours previous to the introduction of acid bleaches were manufactured from sumach-tanned skins only, sumach alone producing a leather of a light cream colour, and therefore capable of taking practically any shade of dye. Most other tanning materials produced dark foundations, on which it was practically impossible to dye any but a dark shade. Gradually, however, manufacturers found leather tanned with materials cheaper than sumach could be scoured and bleached with acids, then re-tanned with sumach, thus producing a light, even-coloured leather, which with the dye produced light shades. The cheapest, and at the same time the most effective, acid for this purpose was vitriol or sulphuric acid. This, in common with other mineral acids, combines with the leather fibre, upon which it exercises a most disastrous and disintegrating action, and to the use of this acid, either as a bleaching or clearing agent in the tanning process, or in subsequent use in developing the colour in the dye-bath, may be ascribed the cause of decay of over 90 per cent. of modern bookbinding[21] and upholstering leather. It is impossible to remove these acids from leather by any subsequent amount of washing, or without the addition of some other chemical to expel them. Recently the writer treated some leather with sulphuric acid, and after cutting the leather up into small pieces, washed the same in running water for three weeks; at the end of that period the sulphuric acid was still tightly fixed in the fibres of the leather.

The introduction of aniline dyes instead of the older process of wood dyes made a great change in the production of bookbinding leather. Hundreds of new shades of colour were produced, and the process of leather dyeing was simplified and cheapened. But, unfortunately, in the use of a certain class of these dye-stuffs the full depth of shade could not at that date be produced upon the leather except in the presence of an acid. Here, again, therefore, sulphuric acid was introduced into the leather during the process of manufacture, thus increasing the proportion of leather which contained this disintegrating material. It has frequently been stated by leather dyers and others that a certain quantity of sulphuric acid must be used with acid dye-stuffs, otherwise the full depth of shade cannot be produced, and they claim that without its use it is impossible to produce certain brilliant shades of colour. These statements have been proved to be devoid of foundation. There are several substitutes for sulphuric acid which are harmless in their nature. Among these I may mention formic, acetic and lactic acids. These are organic acids which have no harmful action on the leather; they are easily washed out, and even if any trace of these acids be left in the skin, they will evaporate. Formic acid has even been proved to be cheaper than sulphuric, and, moreover, is capable of developing equal shades in all cases, and deeper and more brilliant shades of colour with some dyes. For the present, however, bookbinders, and especially librarians, are advised not to insist upon brilliant shades of colour.

The introduction of the splitting machine and the introduction of a machine for shaving leather has undoubtedly tended to produce a large quantity of thin leather, but it is impossible either to shave or to split a skin without cutting the network of fibres, and the strength of the leather cannot but be materially decreased. Leather is made up of a complex system of fibres interweaving and intertwining in every possible direction, and even the small amount of paring carried out by the bookbinder himself considerably impairs the strength and life of the binding. How much more, therefore, does the splitting and shaving that the tanner carries out in order to bring the skin to an even substance destroy the strength of the product.

Sufficient has been written on the printing of morocco, seal, and pig grains upon skins of an inferior class, but it cannot be too strongly pointed out to librarians that the strength of embossed leather must be impaired when it is realised how the embossing and printing is carried out. The skins to be embossed are coated over in the wet state with a mixture of dye, size, and other materials, and are then passed between two hot electrotype rollers. This embosses or prints upon the skin the required grain; at the same time it glues the fibres of the leather together, preventing the free run which good skins should possess, and the heat dries up the leather, reducing its strength very considerably.

I now come to the stripping, scouring, souring, and re-tanning of leather. It is difficult to decide whether more damage is done in this process or in the use of mineral acids in the dye-bath; but it is certain that any leather which is stripped of its natural tanning by use of alkalies or bleached by an acid has lost at least 90 per cent. of its wearing and lasting properties. Thousands of dozens of skins in the rough tanned condition reach the English market from India, Australia, New Zealand, and other parts. These are tanned with quebracho, mimosa, or some similar tanning material, whereas the Indian[23] skins are nearly all tanned with turwar bark and are of a reddish-fawn shade of colour. These are purchased by the leather finishers, and are manufactured in England. In order to get rid of the reddish colour they are first soaked in water and afterwards drummed in a weak solution of washing soda, borax, or some similar alkali. This removes the uncombined tan from the skin, as well as taking out the natural grease. The skins emerge from the drum a dark mahogany colour; they are then washed in water and afterwards soured in a sulphuric acid bath. This bleaches the skin to a light bright shade. The finisher then, in order to put back tannin into the skin of a light colour, re-tans them in sumach or a mixture of sumach and oak. They are now known as re-tanned skins; and after drying, are dyed and finished in the ordinary manner. The sheep and goat skins are sold as roans or moroccos, as the case may be, and, as a rule, no indication is given that these are re-tanned skins. The re-tanned Indian skins, however, generally leave the factory as persian roans or persian morocco, but as the skins pass from the manufacturer to the merchant, from the merchant to the small dealer, the word “persian” is generally omitted, and they reach the bookbinder as moroccos or roans, as the case may be. Now this is the most important point for the binder. I would go so far as to say that it should almost be a punishable offence to use either persians or re-tanned skins for bookbinding purposes, as such leather cannot possibly last ten years if exposed to light and air. Not only has the scouring and alkali a perishing effect upon the leather, but it is afterwards made worse by the treatment with acid, a bleach, and the further addition of acid to the dye-bath; added to which the alkaline treatment removes the natural grease or nourishment of the skin, and it is well known to those engaged in the leather trade that the strength and life of a leather is at least doubled by a proper nourishment of the leather with a suitable fat. Therefore, if the whole of the natural fat[24] is removed, the leather rapidly dries, it loses its elasticity and spring, the grain cracks, and after keeping in a dry library for some time the backs break right off the books.

I have dealt with the eight chief causes of premature decay, but before passing to the other part of this paper I must also deal with the weaknesses of the bookbinder as well as those of the leather manufacturer, and, for reasons stated above, absolutely condemn the undue paring of leather, the bleaching of leather by means of oxalic acid, and the use of patent finishes and glares, the composition of which is in most cases a mystery, many of them containing acids, others containing drying agents which have almost as injurious an action upon leather as the vitriol used by the tanner.

To revert to my original thesis, it is not only possible to obtain a leather as good as any leather manufactured from the 16th to 18th century, but it is even possible to get a better leather. Librarians, in drawing up their binding specifications have only to do what the Controller of H.M.’s Stationery Office is doing for the libraries under his charge, viz., to provide under suitable penalties that leathers supplied by the contractor shall be equal to samples shown on pattern cards prior to tendering for the contract, and in addition to insist that such leathers shall conform to certain conditions laid down in the Report of the Society of Arts’ Committee on Bookbinding, which may be summarised as follows:—

1. The binder undertakes not to use stripped and re-tanned leather, whether persians (East Indian skins) or from elsewhere, or to use leather embossed or grained artificially to resemble morocco, pigskin, &c.

2. He guarantees (or undertakes to produce the guarantee of the firm supplying the leather) that all skins supplied (1) are genuine as described; (2) are tanned with pure sumach or galls, or in the case of calf or sheep with oak bark, or mixtures of oak bark and sumach;[25] (3) that no mineral acid has been used either in the process of tanning, bleaching, or dyeing, and that the leather is free from acid or other injurious ingredient; (4) that he will use no acid to clear the leather in the process of binding.

Before drafting his binding specification the librarian would do well to consult the excellent “Note on Bookbinding” by Mr. Douglas Cockerell, published by W. H. Smith and Son, at the price of 1d. Special attention is drawn to the difference of the cost in binding according to Specification I. and II. of the Society of Arts’ Committee reproduced on pp. 20-22 of this pamphlet, and to Mr. Cockerell’s remarks on pages 9, etc.

The above stipulations should not make any substantial difference in price per volume to those libraries which already have been using high-class leather tanned in sumach, but librarians who have hitherto been content with persians, re-tanned Australians, and other cheap classes of leather must expect to pay a higher price for leather, properly tanned and guaranteed to last. Several large firms of high reputation, who are now catering for the bookbinding trade, have already turned out thousands of skins of a satisfactory nature. These firms are not only anxious to fall in with the requirements of the Society of Arts’ Report, but are desirous of removing the distrust which at present exists with regard to leather, and to reinstate this article as being the standard and natural covering for books. For permanent wear, whether for books or other purposes, leather, when properly prepared, is without a rival both for appearance and durability. It is only for the cheaper class of work that leather substitutes are formidable as rivals.

With regard to strengths of various leathers, it is somewhat difficult to lay down a hard-and-fast rule, but in general terms it may be stated that the strongest leather made is pigskin. The fibres are tough, somewhat coarse, but of great strength. The only danger is[26] in the paring down of the skin previous to use in the binding, and therefore, by reason of its thickness, it is well to only use pigskin for the binding of large, heavy volumes where a thick leather can be used without detriment to the appearance of the book. Seal probably comes next in strength. It is tougher than goat skin, and, by reason of the quantity of natural grease which these skins contain, will in most cases remain pliable and wear longer than the average morocco. Seal is closely followed by goat skin. A special feature of goat is the hard grain which it possesses. This is specially to be recommended where much frictional wear is given to the book. Sheep and calf may be put on about the same footing. Both are extremely pliable, but I think one may safely state that books bound in sheepskin leather, if that leather be from the cross breed, Welsh, or other mountain sheep, will probably outlast calf skin. There is no doubt that calf has got into disrepute largely on account of the destructive processes used in the finishing and production of the soft, smooth-grained calf, which has of late years become so popular. Binders must understand that the velvety finish can only be obtained by an undue pulling down of the skin previous to the tanning process or an undue paring on the part of the binder. Both Russia leather and vellum, as binding materials, have done good service in the past, but have lost their old reputation for durability. For the present, librarians are recommended to use these skins as little as possible. A few words suffice to deal with skiver bindings. These are the thin grain of sheep and sometimes calf, and are at their best about equal in strength to thin notepaper, their whole texture and fibrous structure having been split off and their nature destroyed.

It must be understood that the deterioration of leather is not only caused by faulty manufacture or improper treatment in the dye-house or finishing shop. Good bindings of sound leather are frequently destroyed by the neglect of certain elementary precautions on the[27] part of the librarian. The subject is too large to deal with fully in these pages, but librarians would do well to study carefully the detailed report of the Society of Arts’ Committee. But the following elementary rules should be observed:—Books should not be exposed to gas fumes, or to the direct rays of the sun; the temperature of the library should not exceed 70° F., the upper strata should be well ventilated, and a thermometer should be hung on the same level as the top shelves in order to advise the librarian whether the temperature is being kept within reasonable limits. Freedom from damp is, of course, an essential condition of library architecture.

The question of leather preservative compositions is dealt with in another chapter, but too much cannot be said against the use of various decoctions which are sold to librarians for coating and preserving leather bindings. Many of these contain turpentine, which has a drying, detrimental effect. Various other emulsions are on the market, but although these give the leather a soft, pleasant feel when applied, this soon dries up, the leather becoming hard and liable to crack. There may be some suitable ingredients for applying to leather bindings, but I am of the opinion that if a library is not allowed to get too hot, and a plentiful supply of pure, dry air is always present, sound leather should require no further preservative.

CHAPTER III.

To correctly locate the sources of skin supply suitable for bookbinding is not easy, in consequence of original breeds having been transplanted to equally suitable climes over the seas. In many cases purity of breed has been maintained, while in the majority, deterioration has set in, due to desire for heavier beasts: therefore the purposes of this chapter will be best met if original breeds are described and their general habitat located. The animals which furnish skins suitable in quality and quantity to meet the increasing demands of to-day are: sheep, goat, calf, seal, and pig or hog. Other animals may produce skins good for bookbinding, but a description of the foregoing will afford ample illustration.

The sheepskin takes first place in regard to quantity. Probably more than two-thirds of modern commercial bindings are represented by this much-abused skin, which is frequently so skilfully manipulated as to deceive even an expert, that it is not what it is represented to be. After the pelt has been split or cut in twain—the grain part after tanning being termed “a skiver,” and the flesh after dressing designated chamois—the former is so manipulated with dyes, finishes, and embossing, that surface or grain detection is extremely difficult, say, between a true morocco or embossed skiver. Much of this so-called misrepresentation has been created by the public, who order their books to be covered in “leather,” which they are pleased to think is morocco, or pig or seal, when reflection should tell them that it cannot be genuine at the price they have paid, often for book and binding[32] complete. This “faking” is very largely accomplished upon sheepskin, because it readily lends itself to such alterations both by nature and price; but when such leathers are employed they should be correctly described by the binder. Sheepskins have a large place in the commercial bookbinderies and affections of the public at large, and there is no reason why they should not only hold their ground, but succeed in displacing the cloth imitations of leather; and, provided the skins are selected from suitable breeds, they should find a place in the binding of certain classes of books intended for permanent reference in libraries.

The sheep as a family are divided into two classes: the Upland and Lowland breeds. The Upland class inhabit the mountain ranges, and while possessing a short firm wool, have a mass of close thick hair underneath. Their habits and life make the character of meat and skin approach a goat nearer than any other animal. The parent stock are the argali or wild sheep of the Himalaya, and the “Musmon” of the Andes and Sierra Nevadas. Fuller particulars will be found in the “Royal Natural History,” by Richard Lydekker, B.A., F.R.S., Vol. 2, pp. 212 to 234. The Upland sheep of to-day vary in purity or closeness to the parent stock according to the source of supply. In certain Mongolian, Arabian and Welsh sheep it is not easy to discriminate between them and a true goat, after the wool has been removed. It is the skins of such sheep that are suitable for binding books in libraries where price and hard wear are a consideration. Sheep-grazing countries having high altitudes would be probable sources of supply of such skins. Great Britain, through Wales, Cumberland, Westmorland, and the Highlands of Scotland provides many millions of skins a year to the cotton spinning trade, for covering drawing rollers, an operation calling for a hard-wearing grained skin.

In practice it has been found that sheepskins yield the most lasting results when tanned slowly in oak-bark[33] liquors; the product is a tighter and more solid skin than when tanned in sumach, though sumach may be used in given cases, or a combination of both. Commercially valued, the upland sheepskins sell at prices varying from 2-1/2d. to 9d. per square foot, when finished according to the Society of Arts’ Bookbinding Committee’s Report.

The Lowland breed, commonly known as domestic sheep (Ovis aries) are found wherever there are grazing lands. In sheep grazing, the graziers’ “object” varies. It may be the “wool or the flesh.” If the former, the skin is usually unfavourable for binding purposes, while if the latter, a large portion find their way to the sheepskin splitters, who by machinery of considerable delicacy split the skins into what are known in the trade as grains and fleshes. The grains alone interest us, being subsequently tanned into skivers. This class of leather has its use in low-price trade bindings of flexible character, and as such competes and compares in price and durability successfully with any imitations.

To make skivers suitable in wearing qualities it is advisable to take the plain dyed class, reasonably stout, tanned in sumach, and dyed without mineral acid, dried out with a little stretch left in, and if they are required as tough as it is possible to obtain a grain, a little nourishing material may be used to advantage. By following these lines it will reduce the risk of imitations. Though “paste grain,” "long grain," and “glazed skivers” will still find a market among binders, they must not be classed among the “Imitations.” Skivers are sold from about 1d. to 5d. per square foot.

Before proceeding further it may be well to point out that the skins from old or very young animals should be avoided, although old animals are a rarity. Exceptionally large skins in their class should be viewed with suspicion, likewise very small ones. The former may indicate weakness, and the latter want of maturity. This must in practice have a general application.

The goat (Genus Capra) finds most favour as furnishing a suitable skin among binders. This animal, in the proper sense of the word “goat” exclusive, belongs to the Old World, being confined to the area north of the southern flanks of the Himalaya, though one species is found in Egypt and another in Abyssinia, but quite unknown in the remainder of Africa. In America the term “goat” is applied to our ruminant. While being essentially a mountain animal, goat breeding has become a business to-day throughout the world, which has been laid under contribution to supply the enormous demand which has been created during the past twenty years by the chrome glacé kid manufacturers, one maker alone requiring 5,000 dozen skins per diem to keep his factory running full. The skins generally employed for book purposes are the European and Northern African supplies, though many other sources are equally suitable. Goat skins, on account of their firm nature are best tanned in pure sumach (Sicilian). Time has conclusively proved this point. In the Rylands Library in Manchester (Eng.) are two heavy volumes bound in plain undyed sumach-tanned goat-skins which were bound in Spain in the 16th century, and are to-day in a perfect state of preservation. The Niger skins (mixed goat and sheep) which have found favour among certain bookbinders are produced from a breed of Egyptian goats, tanned and prepared by Nigerian natives with a species of nut-galls which gives them that peculiar close, tight feel, and when such firmness is required in European stock it may be equally effectively produced with oak bark. The large proportion of so-called moroccos offered to-day are made from skins tanned in East India with a catechol tannin. It is unfortunate that this tannage has failed to withstand the tests supplied by the Scientific Committee appointed by the Society of Arts on Bookbinding Leathers, because it excludes from the Binding Trade a very useful and cheap supply of pretty looking and feeling skin ready to hand for finishing in moroccos.[35] While condemned for permanent library work—that is, guaranteed leathers—the writer sees no reason why such leathers may not safely be used for Lending Library work, where the life of a binding is not expected to run more than ten years, provided the surplus tan is washed out and replaced by some nourishing material (fat), and in all processes inorganic acids and alkalis are avoided. Goat-skins differ from other animals mainly in the pronounced grain formations, while the texture of the skin is closer and firmer than a sheep, the grain is harder, more scale like, the papillæ between which the hair-holes are situate are most marked, and it is their formation which produces during the operation of “boarding” the grained morocco with its beautiful nodules. If these nodules or grains are bold and large it indicates a thick skin originally. Such grains cannot be expected upon a thin skin—it implies either over-reduction (shaving) in substance or embossing. Thin skins will produce a small shortlike grain. If the grain is fine on a large skin it may have been reduced too much in substance, and thereby loses most of its muscular structure and strength. It is necessary when buying moroccos, which are not only expensive but are expected to yield longevity and be hard wearing, to obtain a manufacturer’s guarantee that the skins are genuine goat (Genus Capra) and not mountain sheep (Argali) or bastards, and that they have been prepared in accordance with the Society of Arts’ Report on Bookbinding. In value the moroccos vary considerably in price, according to substance, size, quality, and character. The skins are generally bought in the dry pelt state with hair on at per lb., the large, plump, well-flayed skins commanding higher prices than less favoured ones. In this state it is difficult to detect grain faults, consequently to the manufacturer it is somewhat of a speculation, and unless he is well informed in his trade he stands to lose heavily. Generally speaking the prime clear grains go into bright colours at higher prices than[36] defective grains, which can be hidden by darker colour with the aid of a suitable finish. For example, the colour of the Niger skins previously referred to is an excellent one for hiding grain defects. The amount of absolutely perfect skins is small, but the remainder are good skins in their class for half-bound work. The perfect skins will realise up to 2s. 6d. per square foot, and according to quality and colour the balance will range down to 8d. per square foot.

Calf skins have long been favoured for bookbinding, but through much variety of tannages and faulty selection of skins have been brought somewhat into disrepute for permanent work, but if prepared by slow tanning in oak bark or sumach there is no reason why they should not be reinstated. Undoubtedly the calf is favoured by Nature with the finest and silkiest grains of all animals, and though too tender for rough usage, is nevertheless, if suitably nourished, capable of standing greater wear than it is credited with. Calf skins for bookbinding are the product of the domestic ox (Bos taurus), and as this useful animal is bred the world over, we are not wanting in supplies, nor is one land more favoured than another. If the principle is accepted that small books require small thin skins, as the books increase in size so should the skins and substance, a great difficulty will be overcome, because in buying calf one of the fatal mistakes made is the stipulation that large skins must be thin. If this is insisted upon they must be split or shaved of all their muscular tissue till merely the grain or skiver is left. A reasonable amount of shaving is permissible, but splitting is disastrous. Calf skins are invariably free from grain faults, so that for delicate shades of colour they are particularly suitable. The grain does not lend itself to any very definite formation in boarding (graining), therefore calf by preference should be left smooth. In the raw state they are purchased by the pound, and such cost being a governing factor in selling, the price when finished may vary from 8d. to 1s. 8d. per square foot.

The skins of seal (family Phocidæ) are most useful for bookbinding, possessing special features, viz.: evenness of quality throughout, there being no flanky or abdominal parts, extremely durable and producing pretty grains either coarse or fine, dependent upon the substance and character of the skins. The sources of supply are Russia, Norway, Spitzbergen, Greenland, Labrador, and Newfoundland, the largest supply coming from the latter place. Isolated supplies have been shipped from the Falkland Islands and Antarctic. These are the true or earless seals (family Phocidæ), commonly called hair seals in contradistinction to the fur or eared seal (family Otaridæ) which inhabit the Pacifics. As a leather for bookwork when tanned with a pyrogallol tannage it is soft and kind to the touch, having few equals and no superiors. It is essentially a hard-wearing leather and in this respect only equalled by certain classes of goat-skins and pig or hog skins. The “grained” skins exhibit a grain which sparkles in a manner which is peculiarly characteristic and absent in other grained leathers. The value of seal-skins, finished, ranges from 10d. to 2s. per square foot. The former are useful for half-bound books.

Finally, pig or hog skins have played an important part in ancient bindings of all sizes, and proved their great value as a hard wearing cover by coming down to us in a remarkable state of preservation, even on very heavy tomes. But, regretfully, some discredit has been cast upon this splendid skin, partly due to ignorance in manufacture, also to the very clever imitations. It is, perhaps, one of the easiest skins to reproduce in its grain features and solid character, though the imitations are easily detected by immersing a piece of the suspected leather in water until saturated, then pulling it out with the hands to stretch when the grain, which is produced by embossing, will disappear, while the true hog grain will remain showing clear hair holes through from grain to flesh. A hog-skin may be said to be practically fibreless, approaching nearer to a piece of tough gristle than anything[38] else. In the raw state the skins are shipped from southern Europe, Danubian and Balkan States, China and the East generally, while North America has an almost unlimited supply, but Scotland produces the finest and most esteemed. In size they vary considerably, like all skin supplies, but a most useful skin for binders’ use will contain about 11 to 12 square feet. Slow oak-bark tanning is most suitable for this class of skin. Sumach may with advantage be employed after tanning to prepare them for the “dressing” or “finishing” process, but no mechanical or chemical means should be employed to overcome a too gristly nature, otherwise its unique capacity to withstand the act of attrition is proportionately decreased, or if some similar means are adopted to attain evenness of shade in dyeing, the same result may be expected: therefore, so far as it is practicable, this skin should be used in its natural state, if full durability is required.

Pigskins containing 11 to 12 square feet may be purchased, according to their quality and degree of manufacture, from 8d. to 1s. 4d. per square foot.

CHAPTER IV.

What with bad paper and bad leather, the librarian of the present is confronted with two serious problems. In spite of the Society of Arts’ adverse criticism in 1898, much paper is still made of mechanical wood pulp, and more badly overloaded with clay, in both cases causing much anxiety and expenditure to the librarian who attempts to cope successfully with the defect. The soft, spongy leaves, like blotting-paper, that are chiefly composed of wood pulp, can best be dealt with in the very expensive way of inlaying each page in a surround of sound, true paper. But there is another expedient, which I have not tried, which may to some extent be useful; it is to enclose each leaf within a network of fine open silk net, made on purpose. In either case re-sewing and re-binding is necessary.

With regard to the clay-laden paper on which many books are printed, the case is equally serious and equally costly. Fine monotone illustrations produced by the half-tone method, and colour illustrations produced by the three-colour process, are now always made on this sort of paper, which has a beautifully fine and even surface. The paper, however, will not allow any stitching to keep it in place, so it rapidly falls out. Then it has either to be inlaid in a sound paper surround or else entirely mounted on a sound piece of paper or jaconet; and if there are many plates this involves re-binding and an ugly thickening of the book. There is, however, a new method, which may prove of real value: the actual print is made on a very thin paper, which is at once laid down on a sound sheet.

All these operations are expensive as at present provided for in most libraries. They require great care and skill, and take a long time; and it may safely be said that any trustworthy binder entrusted with such work, which is quite out of the ordinary schedule, is fully justified in charging highly for it. The necessary materials are, however, quite simple, so that if there should be a skilled binder on the staff, all such work can practically be done and counted at the cost of time-work only—an immense saving.

There are numerous other small accidents which befall books in all public libraries about which the same things may be said—accidental ink-spots, leaves crushed from a fall, torn places, cut places, damp or wet marks found out in time; all these are expensive to send out and cheap to do on the premises. Besides this, in many cases such as ink-stains or wet an immediate treatment is often quite successful, whereas a delayed treatment can rarely be so.

All this comes under the category of small repairs; but there are other matters which rank a little higher in the bookbinding world which can also be easily and effectively done by a resident binder with few appliances. In all libraries there are a number of pamphlets and thin books which come under the usual binder’s schedule at a fair price, but which, if dealt with by the “stabbed” method on the premises, will be equally strong at about one-third the cost. An ordinary octavo periodical, measuring 10 by 7 inches, and 1-1/4 inches thick, can, with the help of a cheap stabbing machine, be strongly and effectively bound for about 10d., with boards, cloth back, paper sides, and lettered in hand type on a paper label. I showed a specimen to the Library Association on Dec. 18, 1902, when I read a paper on the subject, and it was much approved. I do not advise the stabbing for a book of value, but it does admirably for unimportant books, and is quick and easy to do.

It might be worth pointing out that in binding in this way a collection of pamphlets of the same size, the[43] collection can easily be taken to pieces for insertion of a new piece, if required, without further injury to the pamphlets already stabbed.

Next to this comes binding proper, books sewn with sewn-in bands or flexible, then properly forwarded and finished. This is all skilled work, and if any library is able to afford it there is no question but that a large saving would be effected, both in money and in efficiency, if it would set up a small bindery of its own. I think, however, that it would not be wise to set up such a bindery unless some member of the superior staff has gone through the binding shops and is able to bind a book properly himself. [N.B.—In London the practical knowledge is very difficult to obtain, as the Technical Education Board of the London County Council does not admit amateurs.] Without this knowledge it is impossible to know whether a book is truly or fraudulently bound.

A very common fault is that binders will not draw the ends of the bands of a book properly in to the boards. They cut off the ends of the bands or scrape them so thin that they are of no strength—this is done so that the joint should look quite flat. The result is that when the cloth, buckram, or leather with which the back is covered, gives way, off come the boards; the book is then sent to a binder, who sticks a new strip of leather along the back, and letters it, and charges the same as for re-binding, the operation is done by one’s own binder with own leather, costing about a few pence only. In a properly forwarded book with the bands properly drawn in, the boards are very securely fastened and may well remain so for hundreds of years, irrespective of whatever substance is used to cover the back. If the sewing of an old book is still sound, but the ends of the bands are broken off, new bands can be added by means of tape glued over the old ones and then fastened on to the boards and properly covered with a new bit of leather. Sometimes when they are sound, the remaining ends of old bands will bear a new bit sewn on to them. In all repairs care should be taken to match[44] any old leather that can be retained as nearly as possible. The proper sewing and forwarding of the book is the integral part of the binding, the outer covering is of little real use except for the protection of the threads which in the case of a flexible sewn book would soon wear through if not enclosed. The outer covering of a book, however, has great decorative possibilities and has been for centuries a much valued field for designers, jewellers, enamellers, goldsmiths, and workers in blind and gold tooling. Much fine decorative work done on modern calf and bright coloured leathers will probably perish in a very few years.

The question, therefore, of quality and soundness of the leather used for covering the proper sewing of a book is of much importance. There is strong need for sound leather, which is difficult to get, and ordinary persons, even bookbinders and librarians themselves, cannot by a simple inspection discriminate between new good leather and new bad leather because there is no apparent difference.

We are in the hands of our leather merchants, and although several firms are now willing to sell leathers under guarantee of freedom from sulphuric acid, all are not yet so inclined. I should advise all librarians who do their own binding to accept no leather without a written guarantee of freedom from sulphuric acid, and even then I should send a cutting to Dr. Parker for examination.

With regard to the trade aspect of employing a binder directly to work on a time agreement, I am authoritatively informed that, provided the workman is paid the full trade union wage, and properly located, there is no objection to his employment in this manner. On the other hand, as I have hinted before, I think that such a workman requires some skilled supervision, so here, again, I would urge that in every library one of the superior staff should be a competent binder himself. Given such a skilled supervisor and a small body of skilled binders under his authority, there is no[45] doubt whatever that much money would be saved in the administration of any library, and a multitude of invaluable small repairs would be possible, which under ordinary conditions must be left alone to accumulate and get worse and worse.

I am pleased to say that there are already valuable corroborations of this view in actual working, and I am permitted to cite the case of the Hull Public Library, whose report on the binding for 1901 is before me. During this year I find that the work done comprised—

The cost of the above work was—

| £ | s. | d. | ||||

| Wages | 210 | 4 | 4 | |||

| Materials— | £ | s. | d. | |||

| Millboards | 25 | 8 | 4 | |||

| Cloth | 11 | 2 | 4 | |||

| Tapes | 3 | 3 | 0 | |||

| Paste and glue | 3 | 16 | 6 | |||

| Calico | 7 | 10 | 2 | |||

| Gold leaf | 4 | 9 | 3 | |||

| Leathers | 41 | 8 | 6 | |||

| Thread | 5 | 2 | 1 | |||

| Gas, carriage, &c. | 9 | 8 | 6 | |||

| End papers | 7 | 8 | 6 | |||

| —————— | 118 | 17 | 2 | |||

| —————— | ||||||

| £329 | 1 | 6 | ||||

| ============ | ||||||

The mere enumeration of these materials shows the immense value of the system, enabling the administration to accomplish numbers of small repairs, each of[46] which would have cost very much more if they had been done by an outside bookbinder.

The report for 1902 is similar, but the sum spent is £396 1s. 11d., and the work done was—

In 1903 we find an expenditure of £397 7s. 4d., and work done—

The increased cost in binding “is principally owing to extra labour incurred in preparing the books for sewing, necessary in consequence of the poor quality of paper on which books are now printed, and the method of sewing adopted by publishers.”

Here we begin to find the result of the bad paper of to-day, and we must also note the warning to publishers contained in the last paragraph. I can thoroughly endorse it, and I know that nine out of ten new books are so badly put together that it takes a long time and much trouble to pull them to pieces before they can be properly sewn.

For 1904 there is an expenditure of £416 16s. 6d., and the work done—4,352 volumes bound (average cost 1s. 8-1/2d. per vol.), and various items of mounting ordnance maps, always a very expensive operation, re-sewing, lettering, and miscellaneous repairs, all very necessary and, if sent out, very costly. It will be noted that the cost of binding per volume is steadily increasing, and[47] this not because the work is better done, but because of the bad quality of the paper and sewing as sent out by publishers. Books are sent out fastened by little wire clips, which rust, and have to be very carefully extracted before a book can be properly sewn. These little clips are abominations, and the process of removing them, however carefully done, is likely to cause damage which must be repaired in its turn. Then machine sewing has not yet reached its final stage; there is a difficulty about the return of one of the threads, and it is clumsily brought back by tearing through the upper and lower extremities of each section. This damage is glued up and hidden by a head-band stuck on, but when the book is pulled so that it may be properly sewn, the torn parts have to be laboriously mended.

My thanks are due to Mr. William F. Lawton, the librarian of the Hull Public Libraries, who has most courteously given me the particulars I asked him for; and he tells me further that his books are all half-bound, mostly in sealskin—a very valuable leather; also that he is getting a far better binding both as regards the quality of the materials used and the highest average he mentions, 1s. 8-1/2d. per volume for a satisfactory binding must be something of a revelation to most librarians, whose average, even if they employ the cheapest binder in their neighbourhood, must be very much higher than this, and in all likelihood the work and materials not in any way near the same standard of excellence.

There is another point about an old library which is of much importance, and for which the services of a regular working binder are invaluable. This is the periodical cleaning and polishing of books. It is no use to try to clean old books with water; it will do more harm than good. But until some competent chemist chooses to suggest a proper dressing, it will be found that a good furniture polish is excellent for the purpose. Among the several skilled members employed in my[48] library, one of the best is always cleaning and polishing old books; in fact, old leather really requires some sort of feeding to keep it in sound condition, and the state of perfect repair in which numbers of 15th century books and books of about that date still are is a remarkable testimony to the excellence of old systems of preparing leather and its permanence if carefully kept. Calf, vellum, and goat-skin all last splendidly, but all do better if kept in the dark and under glass; and it must never be forgotten that damp is one of the worst enemies of both paper and leather. Bookcases should never touch an outer wall, but a ventilation space should always be left between the wall and the back of the bookcase. This should even be done when the bookcase abuts on an inner wall. Bookshelves should never be cleaned or washed with water—only use furniture polish; and vellum books should be kept with their backs inwards, the title, if necessary, being written on the fore-edge. Old vellum books were usually kept so in olden times, as light makes vellum brittle like egg-shell.

Books should be close enough on a shelf to support each other; they should not be allowed to flop about; if they are there will be a tendency to fall away from the upper bands, especially in the case of large books. A simple angle iron, the lower wing being inserted under the last few books on a shelf not full, will enable the books to be kept always at the proper lateral pressure.

Big books, such as newspapers, should have a strong handle loop of leather bound in, coming out about the middle of the back.

CHAPTER V.

The following practical hints may be found useful when repairs are required to books in libraries. It is, however, necessary that the librarian or his assistants should gain some technical knowledge of bookbinding, as this will enable them to execute small repairs, which, if promptly done, will probably prevent the expense of rebinding.

The repairing room or small bindery should be not less than 12 feet square, and should have a good natural light. The “plant” required will be as follows:—

| Approximate Cost. | |||

| ——— | |||

| £ | s. | d. | |

| One cutting press, plough, pin and two knives | 1 | 12 | 0 |

| One close tub and cover | 1 | 15 | 0 |

| One stabbing machine | 1 | 8 | 0 |

| One sewing press and keys | 0 | 10 | 0 |

| One pair of millboard shears | 0 | 18 | 6 |

| One pair of shears | 0 | 2 | 6 |

| One paring knife | 0 | 0 | 7 |

| One cutting-out knife | 0 | 0 | 7 |

| One backing hammer | 0 | 2 | 6 |

| One knocking-down iron | 0 | 3 | 6 |

| Two bone folders (thin and thick) | 0 | 0 | 10 |

| One paste tub | 0 | 3 | 0 |

| One glue pot | 0 | 3 | 0 |

| Two paste brushes (small and large) | 0 | 5 | 0 |

| Two glue brushes (small and large) | 0 | 5 | 0 |

| Two pairs of backing boards (octavo and folio) | 0 | 2 | 0 |

| [52] [A] Two pairs of pressing boards (quarto and folio) | 0 | 7 | 0 |

| One iron nipping press, 18 by 12 | 5 | 5 | 0 |

| or | |||

| One wooden nipping press, 18 by 12 | 1 | 15 | 0 |

| One ragstone | 0 | 0 | 5 |

| One sandstone | 0 | 0 | 3 |

| One steel straight-edge | 0 | 2 | 0 |

| One square | 0 | 2 | 0 |

| One wooden trindle | 0 | 0 | 6 |

[A] A few stout millboards of the same size as the wooden pressing boards will be required for placing between the books when more than one book is pressed at a time, the wooden pressing boards being used for the top and bottom books. These can be made by pasting together two tenpenny millboards; line each side with stout smooth paper, trim the edges of the boards, so that they are square.

To repair torn leaves.—Paste the edges of the parts torn very neatly, using a little paste, place a piece of tissue paper under the torn part, carefully join the parts, and place another piece of tissue paper over the joint; then place a piece of paper each side of the leaf, and put a weight upon it until the part is dry, then take away the loose tissue paper.

To insert a loose leaf.—Flatten the back edge of the leaf, then place a strip of paper about 1/8 inch from the edge, and paste that part very neatly, insert it in the book, placing it as close to the back as possible, close the book, and place a weight upon it for about three hours.

To replace books in their covers.—If the cover of a book is sound, the book can be inserted again in the following manner:—If it is necessary, re-sew the book on tapes, put new end papers made with a strip of wide linen in the fold, sew these on the book and trim them, paste the tapes on the end papers, knock up the edges of the book as evenly as possible (as they will not be cut) and glue the back, using the glue sparingly, and place a thin piece of linen round the back extending about 1 inch on each end paper; put the book under a weight until the glue is almost dry, then “round” it and afterwards “back” it slightly; place the book again under a weight until the glue is quite dry, glue the back again, and place the book squarely in the old cover; place a piece of paper[53] round the back of the cover, and rub it down with the bone folder until the back of the cover sticks well to the book. After about three hours the glue will be dry, and the book can then be pasted down; open the covers and paste the end paper facing the board, using the brush from the centre to the edges; close the covers and put the book in the nipping press—the pressing boards should be placed carefully against the grooves and not upon them; leave the book in the press for about twelve hours. When a book does not require re-sewing, new end papers should be made as stated and sewn on the book if it has been sewn on tapes; if the book has not been sewn on tapes, the end papers should be edged on in the same manner as the loose leaf, and in these instances the linen should be placed in the fold of the end papers.

Old books which have been bound in leather generally require repairs to the corners and the back, these being the parts which first show signs of decay. Carefully cut away the ragged edges of the old leather along the joints at the back and also the corners; strip the leather off the back and soak it off if necessary, so that the back is quite clean; also take away the old leather from the corners, lift up the edges of the leather along the joints and also at the corners about 1 inch, turn the leather back, and place a thin piece of wooden trindle under the fold, and pare the edges of the leather neatly; if the millboard at the corners is broken, open the edges and rub in some glue, press the edges together, and, when nearly dry, hammer them flat on the “knocking-down iron,” obtain some leather to match the old binding, put a new back, also corners where necessary, on the book, paring the edges of the leather neatly; after these are quite dry, the edges of the old leather should be pasted down to overlap the new leather; wash any smears of paste away, and press the book lightly in the nipping press; new end papers should be edged in as in the case of the loose leaf:[54] trim them to the size of the book and then paste them down, but with the boards open until they are quite dry; place either a tin or a glazed cardboard inside the covers, and keep the book pressed in the nipping press for about six hours.

When corresponding with Advertisers, please mention

“Leather for Libraries.”

Under an arrangement entered into between the Council of the Library Association and Dr. J. Gordon Parker, their Official Examiner of Leather, the following Scale of Fees has been agreed upon:—

| Usual Fee. | Special Fee to Members. | |||||

| ———— | ————— | |||||

| £ | s. | d. | £ | s. | d. | |

| Test for Presence of Injurious Acids | 0 | 10 | 6 | 0 | 5 | 0 |

| Quantitative Estimation of Acids | 1 | 1 | 0 | 0 | 7 | 6 |

| Nature of Tannage, if Pure Sumach | 0 | 10 | 6 | 0 | 5 | 0 |

| Full Microscopic Examination | 1 | 1 | 0 | 0 | 5 | 0 |

| Full Examination and Report on Sample of Leather |

2 | 2 | 0 | 1 | 0 | 0 |

Samples of Leather, not less than six square inches, may now be sent to

Dr. J. GORDON PARKER,

Herold’s Institute,

Drummond Road,

Bermondsey.

Correspondence on above may be addressed to the Hon. Sec., Sound Leather Committee of the Library Association, Whitcomb House, Whitcomb Street, W.C.

BEVINGTONS & SONS,

NECKINGER MILLS,

Bermondsey, London, S.E.

Manufacturers of—

Guaranteed Sumach-Tanned and free from Mineral Acids.

--> EVERY SKIN STAMPED. <--

See Samples of our Goat, Seal, and Calf (1-4)

on End Covers.

PIGSKIN

FOR

BOOK BINDING.

MUIR’S

PIGSKIN

BEITH.N.B.

We first introduced this material to the notice of Bookbinders some 25 years ago. Since then it has steadily increased in popularity, as its durability and utility have been demonstrated by this test of a quarter of a century.

WHEREVER HARD WEAR IS WANTED PIGSKIN

IS THE RIGHT THING IN THE RIGHT PLACE.

It is not a fibrous substance as other leather is, but naturally of a compact, gristly character. When skilfully tanned and treated for the purpose, it unquestionably is the best of bookbinding leather.

See Sample of our Pigskin on End Cover.

Available in all colours and substances. Please write for full particulars.

JOHN MUIR & SON,

TANNERS AND CURRIERS,

BEITH, SCOTLAND.

(Established a Century ago.)

Offices: 3, ARUNDEL STREET, STRAND, LONDON, W.C.

Telephone: 4669 GERRARD.

Pigskin Tyre Factory for Vehicles and Motors:

183, BOW ROAD, LONDON, E.

JOHN S. DEED & SONS, Ltd.

Manufacturers of

Best Quality Sumach-Tanned

MOROCCOS AND CALF

And other Classes of Bookbinding Leathers.

| Factories | { Eagle Leather Works, Mitcham and Carshalton, Surrey. |

| { Middlesex ""Arthur Street, London, W.C. |

All Communications to be addressed to Central Works and Offices

91, NEW OXFORD ST., LONDON, W.C.

FINE LEATHERS FOR BOOKBINDING.

Speciality ...

SEALS.

CAPE GOATS.

COLOURED CALF.

Makers also of Best Flexible Skin Glue and .. Roller Compo. ..

EDWARD & JAMES RICHARDSON ELSWICK LEATHER WORKS, NEWCASTLE-ON-TYNE.

J. MEREDITH-JONES & SONS, Ltd.,

CAMBRIAN

LEATHER WORKS,

WREXHAM.

MANUFACTURERS OF

Bookbinders’

Leathers.

Guaranteed to be dressed on the lines

recommended by the Society of Arts

Report, and free from Mineral Acids.

SPECIALITY: WELSH SHEEP.

See Sample of our Sheepskin on End Cover.

Patterns and Prices on application.

AN EFFECTIVE BINDING!

SKIVERS.

Sumach-Tanned Split Sheep

and Lamb Skins.

SPECIALLY ADAPTED FOR POCKET EDITIONS

AND SMALL VOLUMES.

ONLY ENGLISH AND SCOTCH SKINS USED.

JAMES GARNAR & SONS,

The Grange,

BERMONDSEY, LONDON, S.E.

GEO. GIBBS & SON,

29, St. BRIDE STREET,

LONDON.

FACTORIES:—

MITCHAM COMMON, SURREY,

AND

LONG LANE, BERMONDSEY.

MANUFACTURERS OF EVERY DESCRIPTION OF

COLOURED HIDES, CALF, MOROCCO, ROAN, PIGSKIN, and

SKIVER LEATHERS.

ALSO WHITE AND COLOURED VELLUMS, FORELS AND

PARCHMENTS FOR BOOKBINDERS.

A JOURNAL IN EVERY SENSE OF THE TERM.

THE CHAMPION AND SUPPORTER OF THE TRUE INTERESTS OF

THE LEATHER TRADE.

“THE LEATHER

TRADES’ REVIEW.”

THE ORGAN OF THE

HIDE, TANNING, LEATHER

AND KINDRED TRADES.

A PRACTICAL AND THOROUGHLY UP-TO-DATE PAPER,

AND INDISPENSARLE TO ALL LEATHER MEN,

BOTH EMPLOYERS AND EMPLOYÉS.

| EVERY ISSUE WELL WORTH A WHOLE YEAR’S SUBSCRIPTION. | UNEQUALLED AS AN ADVERTISING MEDIUM. |

WORLD-WIDE CIRCULATION.

TECHNICAL AND SCIENTIFIC ARTICLES BY THE LEADING

EXPERTS IN ALL THE BRANCHES OF THE LEATHER INDUSTRY.

LATEST AND MOST RELIABLE NEWS.

ANNUAL SUBSCRIPTION: TEN SHILLINGS

(52 WEEKLY NUMBERS POST FREE).

Office: 24, MARK LANE, LONDON, E.C.

PIG SKINS

IN THE CRUST

FOR

BOOKBINDING LEATHER MANUFACTURERS

Warranted Free of Mineral Acid.

GRYFFE TANNERY COMPANY,

BRIDGE OF WEIR,

Near GLASGOW,

SCOTLAND.

| Telegrams: “GRYFFE,” Bridge of Weir. |

National Telephone: No. 8, Bridge of Weir. |

B. RILEY & Co., Ltd.,

LIBRARY BOOKBINDERS

and SPECIALISTS.

Best Work, Best Materials, and Promptness, with

Lowest Prices.

PIGSKINS AND MOROCCOS Guaranteed free from Injurious Acid.

PATENT SEWING AND FLEXIBILITY.

Catalogues, Price Lists, and Quotations by return post.

Note Address:—

Works: WESTGATE, HUDDERSFIELD.

London Office: 376, STRAND, W.C.

Messrs. MUDIE & Co.

Undertake all Classes of Binding for either

PUBLIC or PRIVATE LIBRARIES....

THE BEST WORK and BEST MATERIALS only.

No Imitation Leathers used....

CHARGES FOR LARGE OR SMALL QUANTITIES ON APPLICATION.

Address MANAGER,

BOOKBINDING DEPARTMENT,

MUDIE’S LIBRARY,

NEW OXFORD STREET,

LONDON.

IMPORTANT TO LIBRARIANS.

George F. Banting,

Danemere Works, Danemere Street, Putney

(Hitherto trading as J. Banting & Son, Chelsea),

Specialist in Public Library Bookbinding.

The only binder in London who has made a speciality of Public Library Bookbinding.

Testimonials from Customers for Continuous Work for 18 years.

BOOKS BOUND IN SOUND LEATHER AS PER SOCIETY OF ARTS RECOMMENDATION.

A Trial Order will prove that Books Bound by me are “Bound once for All.”

| Telegrams and Cables: “CLEANING, ECCLES.” Code: A.B.C., 5th Ed. |

Stores: LONDON. LIVERPOOL. |

THE “TIGER” SUMAC COMPANY.

“TIGER” REGISTERED BRAND.

THOMAS ATKIN, Proprietor.

ECCLES, ENGLAND.

Purity and 26 per cent. minimum Tannin guaranteed by I.A.L.T.C. Analysis.

Analyst, Dr. Andrew Turnbull, 3, Lord Street, Liverpool, whose determination in every case must be final.

Average Test of all our Shipments from September 1, 1904, to July 31, 1905,

29·7%, or 14 per cent. beyond our guarantee.

Free copy of Analysis given with orders for 10 Tons and upwards.

Shipments made c.i.f. from Palermo to any port in the world.

STOCKS KEPT IN LIVERPOOL AND LONDON FOR THE HOME TRADE.

A SPECIAL SUMAC FOR THE FINEST LEATHERS.

Agents—Messrs. POPPLETON, GIBBS & Co., 4-5, Leather Market, London, S.E.