Title: Rubber Hand Stamps and the Manipulation of Rubber

Author: T. O'Conor Sloane

Release date: December 23, 2021 [eBook #66998]

Language: English

Original publication: United States: Norman W. Henley

Credits: deaurider, Charlie Howard, and the Online Distributed Proofreading Team at https://www.pgdp.net (This file was produced from images generously made available by The Internet Archive)

Transcriber’s Note

Larger versions of most illustrations may be seen by right-clicking them and selecting an option to view them separately, or by double-tapping and/or stretching them.

BY THE SAME AUTHOR.

Arithmetic of Electricity.

A Complete and Indispensable vade mecum for amateur, student, and electrical engineer.

Fully Illustrated. Price, $1.00.

Home Experiments in Science.

252 Pages. 96 Illustrations. Price, $1.50.

A PRACTICAL TREATISE ON THE MANUFACTURE OF INDIA RUBBER HAND

STAMPS, SMALL ARTICLES OF INDIA RUBBER, THE HEKTOGRAPH,

SPECIAL INKS, CEMENTS, AND ALLIED SUBJECTS

BY

T. O’CONOR SLOANE, A.M., E.M., Ph.D.

Author of

“Home Experiments in Science,” “Arithmetic of Electricity,” etc.

FULLY ILLUSTRATED

NEW YORK

NORMAN W. HENLEY & CO.

150 NASSAU STREET

1891

Copyright, 1890, by

NORMAN W. HENLEY & CO.

iii

The present work hardly needs a preface. The object is to present in the simplest form the subject of the manipulation of india rubber. To mould and cure the mixed gum but few appliances are needed, and these can be made at home. The articles produced are of more than ordinary utility. These two facts give value to the art and furnish a raison d’être for this book. If its instructions do not prove practical it will have missed its object.

For some reason the methods of moulding the material are not generally known. Experiment has taught many the futility of attempting to melt and cast it. While thus intractable by the usual methods, it is the most plastic of materials when properly treated. Its power of reproducing the finest details of a mould, of entering all the intricacies and undercuttings of a design, cause one to feel a peculiar pleasure in working with so responsive a material. It is not saying too much to affirm that to some readers this book will disclose a long hidden secret. To make it more generally useful it is writteniv for such readers, to meet the want of those knowing of the subject. It was felt that in following this course, and in treating the subject from its first steps, including the simplest as well as most advanced methods, the book would appeal to a larger body of readers.

The allied subjects to which some chapters are devoted will be acceptable to many readers. The hektograph is given in several modifications. A substitute for rubber stamps which stands the severe usage of the Post Office has very distinct merits, and the manufacture is accordingly described in detail. Cements and inks embody many special formulæ. In the last chapter interesting and practical notes will be found.

For the use of certain cuts we are under obligations to the Buffalo Dental Manufacturing Co., Messrs. E. & F. N. Spon & Co., and to Mr. L. Spangenberg.

v

| PAGE | |

| CHAPTER I. | |

| THE SOURCES OF INDIA RUBBER AND ITS HISTORY. | |

| The Trees—The Sap—Caoutchouc—Early Uses by the Indians—First knowledge of it in Europe—Goodyear, Day, and Mackintosh | 9 |

| CHAPTER II. | |

| THE NATURAL HISTORY AND COLLECTION OF INDIA RUBBER. | |

| African, East Indian, Central and South American Gums—Different Methods of Collection and Coagulation | 15 |

| CHAPTER III. | |

| PROPERTIES OF UNVULCANIZED AND VULCANIZED INDIA RUBBER. | |

| Properties of Unvulcanized Rubber; its Cohesion and importance of this property—Analysis of Sap and Caoutchouc—Effects of Heat and Cold—Distillation Products—Vulcanized Rubber, and its Properties | 24 |

| CHAPTER IV. | |

| THE MANUFACTURE OF MASTICATED, MIXED SHEET AND VULCANIZED INDIA RUBBER. | |

| Treatment by the Manufacturer—Washing and Sheeting—Masticating—Makingvi Sheeting and Threads—Mixing—Curing—Coated Tissues | 35 |

| CHAPTER V. | |

| INDIA RUBBER STAMP MAKING. | |

| Mixed Sheet—Outlines of Moulding—Home-Made Vulcanizing Press—Further Simplifications of Same—Securing Accurate Parallelism of Platen and Bed—Distance Pieces—Wood vs. Iron as Material for Press—Use of Springs on the Home-Made Press—Metal Flask Clamps—Large Gas-Heated Vulcanizing Press—Preparing Type Model—The Matrix—Plaster of Paris and Dental Plaster as Substances for Matrices—Dextrine and Gum Arabic Solutions for Mixing Matrix—How Matrix is made—Shellac Solution for Matrix—Matrix Press and Spring-Chase—How to retard the Setting of Plaster of Paris—Oxychloride of Zinc Matrices—Talc Powder—Moulding and Curing the Stamp—Kerosene Heating Stove—Manipulation of Press—Degree of Heat—Simple Test of Curing—Time Required—Combined Matrix Making and Vulcanizing Apparatus—Chamber Vulcanizers—Object of Steam in Vulcanizers—Temperature Corresponding to Different Steam Pressures—Jacketed Vulcanizers—Gas Regulator—Flower Pot Vulcanizer—Fish Kettle Vulcanizer—Making Stamps without any Apparatus Whatever—Notes on Type, Quadrats and Spaces—Autograph Stamps | 47 |

| CHAPTER VI. | |

| INDIA RUBBER TYPE MAKING. | |

| Movable Type Making—Simple Flask and Matrix—Precautions as to Quantity of Rubber—Moulding—Curing—Cutting Type Apart—Special Steel Moulds—Wooden Bodied Type | 73vii |

| CHAPTER VII. | |

| THE MAKING OF STAMPS AND TYPE FROM VULCANIZED INDIA RUBBER. | |

| Ready Vulcanized Gum as Material for Stamps—Simplicity of the Process of Using It—Advantages and Disadvantages—Availability for Type | 77 |

| CHAPTER VIII. | |

| VARIOUS TYPE MATRICES FOR RUBBER STAMPS AND TYPES. | |

| Electrotype Matrices—Papier Maché—Flong Paste—Flong Matrices—Beating into Model—Drying and Baking—Struck-up Matrices—Chalk Plates | 80 |

| CHAPTER IX. | |

| THE MAKING OF VARIOUS SMALL ARTICLES OF INDIA RUBBER. | |

| Suction Discs—Pencil Tips—Cane and Chair Leg Tips—Corks—Mats—Cord and Tubes—Bulbs and Hollow Toys | 85 |

| CHAPTER X. | |

| THE MANIPULATION OF SHEET RUBBER GOODS. | |

| Sheet Rubber Articles—Toy Balloons—Uses of Sheet Rubber in the Laboratory | 94 |

| CHAPTER XI. | |

| VARIOUS VULCANIZING AND CURING PROCESSES. | |

| Liquid Curing Baths—Sulphur Bath—Haloids and Nitric Acid as Vulcanizers—Alkaline Sulphides—Sulphur Absorption Process—Parke’s Process | 97 |

| CHAPTER XII. | |

| THE SOLUTION OF INDIA RUBBER. | |

| Mastication with Solvent—Peculiarities of the Process—Differentviii Solvents and their Properties—Paraffin—Vulcanized Rubber Solution—Aqueous Solution | 103 |

| CHAPTER XIII. | |

| EBONITE, VULCANITE AND GUTTA-PERCHA. | |

| Ebonite and Vulcanite—Manufacture—Manipulation—Gutta-Percha and its Manipulation | 108 |

| CHAPTER XIV. | |

| GLUE OR COMPOSITION STAMPS. | |

| Substitute for Rubber Stamps—The United States Government Formula—Models and Moulds—Dating—Handles | 113 |

| CHAPTER XV. | |

| THE HEKTOGRAPH. | |

| How Made—The French Government Formula—Hektograph Sheets | 121 |

| CHAPTER XVI. | |

| CEMENTS. | |

| Marine Glue, and other special Cements | 125 |

| CHAPTER XVII. | |

| INKS. | |

| Hektograph, Stencil and Marking Inks—White and Metallic Inks | 129 |

| CHAPTER XVIII. | |

| MISCELLANEOUS. | |

| Preservation and Renovation of India Rubber—Burned Rubber for Artists—India Rubber Substitutes—General Notes of Interest | 134 |

9

India rubber or caoutchouc is a very peculiar product, which is found in and extracted from the juice of certain trees and shrubs. These are quite numerous and are referred for the most part to the following families: Euphorbiaceæd, Urticaceæd, Artocarpeæd, Asclepiadaceæd, and Cinchonaceæd. It is evident that a considerable number of trees are utilized in commerce for its production, and it is certain that it exists, quite widely distributed, in many cases as a constituent of the juice of plants not recognized as containing it.

When an india rubber tree is tapped, which is effected by making incisions in the bark, the sap of the tree exudes. It is a milky substance and is collected in various ways; it may be in vessels of10 clay, in shells, or in other receptacles by the india rubber hunters. If this substance is examined it is found to be of very remarkable and characteristic constitution, resembling in its physical features ordinary milk. It is composed of from fifty to ninety per cent. of water, in which is suspended in microscopic globules, like the cream in milk, the desired caoutchouc or india rubber. If the juice is left to stand in vessels, like milk in a creamery, the globules rise to the surface, and a cream of india rubber can be skimmed off from the surface. If the juice is evaporated over a fire, the water escapes and the india rubber remains. By dipping an article repeatedly in the juice and drying it, a thick or thin coating of india rubber can be developed. Before the modern methods for the manipulation of the gum had been developed, and before the invention of vulcanization, this method was adopted for the manufacture of shoes. The original “india rubbers” for protection of the feet in wet weather were made in this manner. A clay last was used, upon which the india rubber was deposited as described. The clay last was then broken out and removed. Great quantities of overshoes were thus made in South America, and many were exported to Europe.

When caoutchouc has once been removed from this watery emulsion, which for all practical purposes is a solution, it cannot be restored to the former state of liquidity; it remains solid. It will11 absorb a considerable quantity of water, but will not enter again into the quasi solution or combination. This property of permanent coagulation, which interferes to a degree with its easy manipulation, was early discovered. In the last century quantities of the natural milk were exported to Europe to be used in what may be termed the natural process of manufacture, because once solidified it could not be redissolved, and because the manufacturers of those days had not the present methods of dealing with the apparently intractable gum.

The natives of South America before the advent of Europeans, were familiar with the treatment of the juice by evaporation just described and used to make bottles, shoes and syringes of it for their own use. The name Siphonia applied to several species of rubber tree, and seringa (caoutchouc) and seringari (caoutchouc gatherer) in Spanish recall the old Indian syringes and tubes.

The gum is now collected for export in many parts of the world. South and Central America are, as they have always been, the greatest producers. Some is collected in Africa, Java and India. The best comes from Para. However carefully treated a great difference is found in the product from different countries. The Brazilian india rubber, known as Para, from the port of shipment, ranks as the best in the market.

Its history as far as recorded, does not go back of the last century. Le Condamine, who explored the12 Amazon River, sent from South America in 1736 to the Institute de France, in Paris, the first sample of india rubber ever seen in Europe. He accompanied the sample with a communication. He said that the Indians of that country used the gum in making several domestic objects of utility, such as vessels, bottles, boots, waterproof clothing, etc. He stated that it was attacked and to a certain extent dissolved by warm nut oil. In 1751 and 1768 other samples were received through MM. Fresnau and Maequer, who sent them to the Academy of Sciences, Paris, from Cayenne in Guiana.

Although from this period numerous experiments were tried with the new substance little of importance was done with it for many years. Its first use was to rub out pencil marks, whence it derived its name of “india rubber.” As late as 1820 this continued to be its principal use.

An interesting reminiscence of its early history is given by Joseph Priestley, the great English chemist of the last century, celebrated as the discoverer of oxygen. In 1770 he mentioned the use of the gum for erasing pencil marks, and speaks of its cost being three shillings, about seventy cents, for “a cubical piece of about half an inch.”

As we have seen, its solubility was early studied. In 1761 Hérissant added turpentine, ether and “huile de Dippel” to the list of solvents. In 1793 its solubility was utilized in France by Besson, who made waterproof cloth. In 1797 Johnson introduced13 for the same manufacture a solution in mixed turpentine and alcohol.

The year 1820 is the beginning of the period of its modern use on a more extended scale. Nadier developed the methods of cutting it into sheets and threads and of weaving the latter. Mackintosh in 1823 began the manufacture of waterproof cloth, using the solution of the gum in coal tar naptha, which was caused to deposit by evaporation a layer of the gum upon a piece of cloth which was covered by a second one. This protected the wearer from the gummy and sticky coating of raw india rubber. At the best the original Mackintoshes must have been very disagreeable articles for wear.

In 1825 india rubber shoes of raw india rubber were imported from South America and formed for a while an important article of commerce.

In 1839 Charles Goodyear, of Massachusetts, invented the art of vulcanizing, or combining india rubber with sulphur. It was patented on June 15, 1844, and covers only the manufacture of soft rubber. Vulcanite or hard rubber (whalebone rubber) is disputed as to its origin, its invention being assigned by some to Nelson Goodyear and by others to Austin G. Day, of Connecticut. Goodyear however succeeded in obtaining a patent on May 6, 1851. Day obtained a patent on August 10, 1858.

Vulcanization is the most important invention ever made in connection with india rubber and may fairly rank as one of the greatest discoveries of the14 present century. It is claimed by the English, an inventor named Handcock being cited as the rival of Charles Goodyear. The latter inventor had as an associate Nathaniel Hayward, who is probably entitled to some of the credit.

By vulcanization india rubber loses susceptibility to heat and cold, becomes non-adherent, and insoluble in almost all substances. It is converted from a comparatively useless substance into one of wide applicability.

The subject of india rubber is so interesting in its theoretical as well as practical bearings that it seems impossible that those who are workers in it should not feel an interest in its natural history. For such readers the chapter on the natural history and collection of india rubber has been written. As it is a product of widely separated lands on both hemispheres, and as it is yielded by an immense number of plants, it is impossible in the limits of a chapter to give a full outline of its natural history.

The chapter in question is, therefore, with this apology, inserted where it belongs, near the beginning of the book. Those who are entirely practical may pass it over. There is no doubt that the few minutes necessary for its perusal will be bestowed upon it by some.

15

African india rubber is mostly exported from the west coast. The belt of country producing it extends nearly across the continent. Those who are familiar with the india rubber plants of our conservatories are apt to think of the gum as the product of trees, but in Africa it is largely yielded by climbing plants of very numerous varieties, belonging generally to the Landolphia species. It is collected by the natives by careless or desultory methods, probably less advanced than the ways followed by the South Americans. Possibly its marked inferiority may be partly attributed to this. It is also supposed by many that, were the gathering restricted to the vine producing the best gum, better results would follow. As it is now all gums are mixed indiscriminately. African gum is of very inferior quality.

The African india rubber vines grow often in dark moist ravines, where no valuable product other than themselves could be cultivated. They are entirely wild. The vines when cut exude an abundance16 of sap, which differs from the South American product in its quickness of coagulation. As it escapes from the wound it at once solidifies and prevents the further escape of juice. The negroes are said to employ the following highly original method of collecting it. They make long gashes in the bark. As fast as the milky juice comes out they wipe it off with their fingers and wipe these in turn on their arms, shoulders, and body. In this way they form a thick covering of inspissated juice or caoutchouc over the upper part of their body. This from time to time is removed by peeling. It is then said to be cut up and boiled in water. This is one account. According to others the natives remove a large piece of bark, so that the juice runs out and is collected in holes in the earth or on leaves. Wooden vessels are said to be used elsewhere. Sometimes the juice is said to be collected upon the arms, the dried caoutchouc coming off in the shape of tubes. A clew to the inferiority of African india rubber is afforded by the statement that too deep a cut liberates a gum which deteriorates the regular product if it mixes with it. The drying of the gum is thought to have much to do with its quality and it is highly probable that this affects the African product. Some samples seem to be partly decomposed they are so highly offensive in odor. The South American rubber is often dried in thin layers, one over the other, by a smoky fire, which may have an antiseptic effect upon the newly17 coagulated caoutchouc. No such process as far as known is used in Africa.

The African india rubber appears under different names in commerce. From the Congo region lumps of no particular shape called “knuckles”; from Sierra Leone smooth lumps, “negro-heads,” and “balls” made up of small scrap; from the Portuguese ports “thimbles,” “nuts,” and “negro-heads;” from the gaboon “tongues;” and from Liberia “balls” are received. It is all characterized by great adhesiveness and low elasticity.

From Assam, Java, Penang, and Rangoon there is considerable gum exported. It is supposed to be the product of trees of the ficus species, in all these places, as it is known to be in Java and Assam. In the latter place rigid restrictions are imposed as far as possible upon the gathering. In the case of wild trees scattered through the forest the carrying out of these restrictions is not practicable. The trees are cut with knives in long incisions through the bark and the juice is collected in holes dug in the ground, or often in leaves wrapped up into a conical form, somewhat as grocers form their wrapping paper into cornucopia shape for holding sugar, etc.

It has seemed reasonably certain that the india rubber producing plants might be cultivated with profit, and it is as certainly to be feared that without such cultivation they will become extinct. Efforts have been made in the direction of raising18 them artificially but without much success. In Assam numerous experiments have been made to propagate the india rubber bearing ficus tree.

A good instance of the ill effects of carelessness in the original gathering of the crop is afforded by the Bornese collectors. The source of Borneo india rubber is a variety of creepers. These are cut down and divided into short sections from a few inches to a yard in length. The sap oozes out from the ends. To accelerate its escape the pieces are sometimes heated at one end. It is coagulated by salt water. Sometimes a salt called nipa salt, obtained by burning a certain plant (nipa fruticans), is used for the purpose. In either case it is coagulated into rough balls and masses. These masses are heavily charged with the salt water, often containing as much as fifty per cent., and rarely much less than twenty per cent.

Central America and Panama are great producers of the gum. In Panama the custom of felling the19 trees is often adopted. In this case grooves are cut around the prostrate trunk, and under each groove as the trunk lies on the ground a vessel is placed to collect the sap. Its coagulation is often effected by leaving it for a couple of weeks standing at rest in a hole, excavated on the surface of the ground, and covered over with leaves. The caoutchouc separates under these conditions. A quicker method, but one yielding an inferior product, is obtained by adding to the fresh juice some bruised leaves of a plant (ipomæa bona nox) which acts something like acid upon milk, in separating the desired solid matter or caoutchouc. A jelly like accretion saturated with blackish water is thus obtained. By working it together a blackish liquid is caused to escape, and comparatively pure gum is gradually obtained. As much as one hundred pounds of india rubber may be obtained from a single tree where this destructive system is employed. Further north, where a better counsel has prevailed, the trees are only tapped, and the india rubber hunter is satisfied if from a tree eighteen inches in diameter he obtains twenty gallons of sap, giving fifty pounds of gum. Even where tapping is done the tree is often destroyed by carelessness or ignorance.

Two systems are followed in Nicaragua. The operator ascends by a ladder if he has one, or in any case climbs as high as he well can and begins to make a long incision. Sometimes he carries one long straight20 cut clear down to the ground. This is made the starting point for a number of side cuts, short, and running diagonally into it. This is also one of the Brazilian methods. The Nicaraguan sometimes also makes two spiral incisions, one right-handed and the other left-handed, crossing each other as they descend so as to divide the surface of the tree into roughly outlined diamonds. In either case the juice flows down to an iron spout, placed at the bottom of the tree, which spout leads to an iron pail. The milk is gathered and passed through a sieve, and coagulated in barrels by the ipomæa plant as before mentioned. This gives three grades of rubber. The bulk is obtained from the barrels and is called often méros; the small lump which forms in the spout is rolled into a ball and called cabezza; the dried strips pulled out of the cuts is of very good quality and is called bola or burucha.

From Brazil is exported the famous Para india rubber. This is of very high quality, and is greatly esteemed by all manufacturers. No process can make a poor gum give a really good product. The system of gathering it varies. Sometimes the tree is cut into by gashes from an axe, such gashes extending in a row all around the trunk. Under each gash a small clay cup is luted fast with some fresh mixed clay. These collect from a tablespoonful of juice upward, which is collected, and the cups are removed on the same day. The next day a second row of cuts is made below the others, and the same21 process is repeated. This is continued until from a point as high as a man can reach, down to the ground the tree is full of cuts. Sometimes a gutter of clay is found partly around the trunk with gashes above it. In other cases a vine is secured around the tree and a collecting gutter is worked with it for a basis.

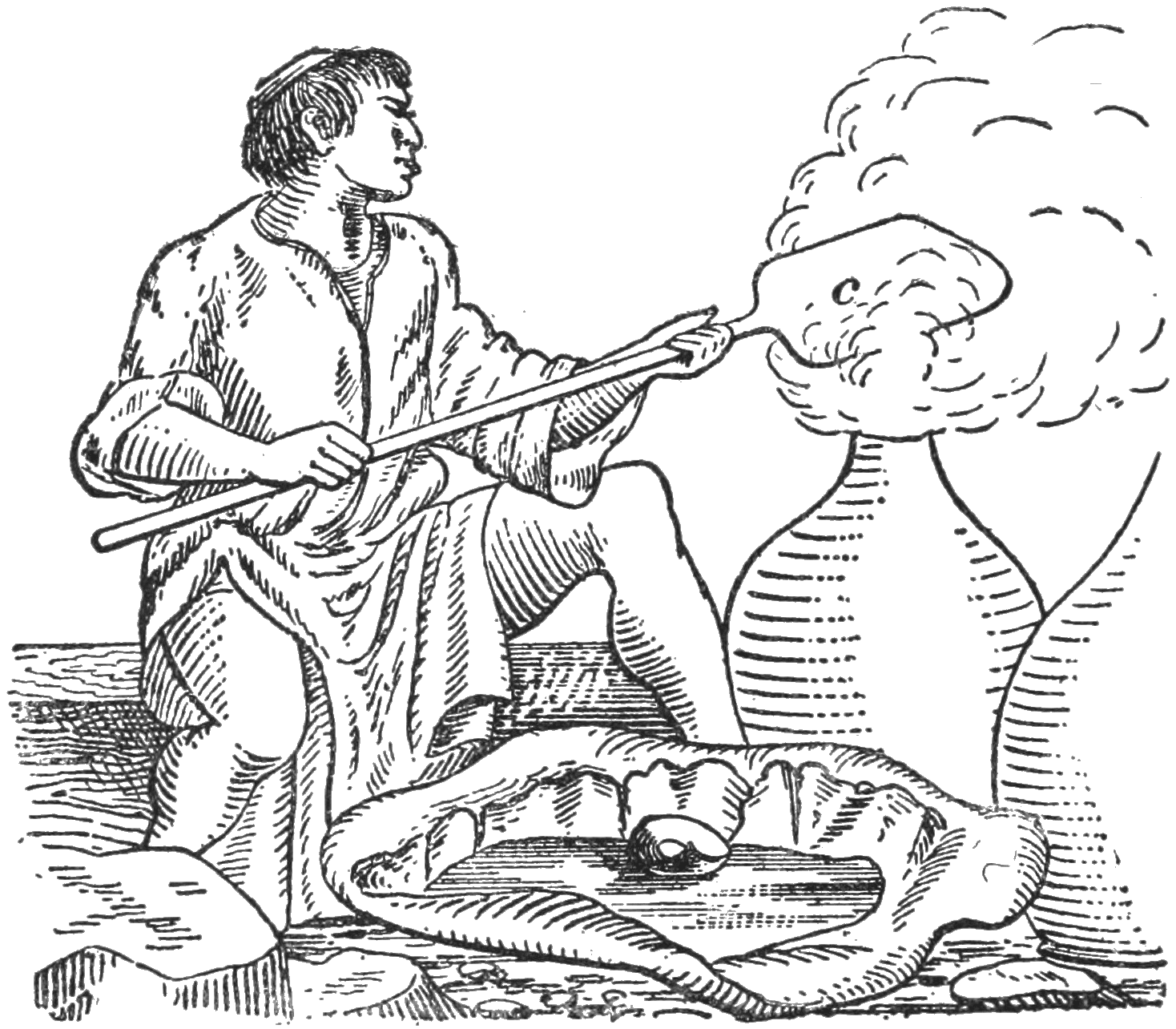

The juice is coagulated in a smoky fire. A bottomless jar is placed over the fire and some palm nuts are mixed with the fuel. The mould, which is often a canoe paddle, is smeared with clay to prevent adhesion and is then heated. A cup of juice is poured over it, and after the excess has dropped off it is moved about rapidly over the smoke and22 hot air which ascends from the mouth of the jar. This series of operations is repeated until the coating is quite thick; it may be as much as five inches. After solidifying over night it is cut open and the paddle or mould is removed. After a few days drying it is sent to market. With all the heating, during which it sweats profusely, it still retains fifteen per cent. of water.

India rubber sap may be coagulated by an aqueous solution of alum. The process has been tried in Brazil, and is used to a considerable extent in23 Pernambuco. It was proposed by an investigator named Strauss, and the process is still called by his name. One objection is that it gives a very wet product, and apparently one of inferior value to the smoked gum.

The feeling that india rubber suffers in the gathering has been so much felt that it has been recently suggested that if possible the uncoagulated juice should be exported to Europe there to be worked up from the beginning.

24

There are two broad divisions to which all varieties of india rubber can be assigned—unvulcanized and vulcanized rubber. Speaking with a certain amount of license it may be said that more properties characterize the former than the latter. The vulcanized article is very slightly affected by ordinary changes of temperature, cannot to any considerable extent be changed by heat short of absolute destruction or decomposition, cannot be united or moulded except in simple forms, is highly elastic, and is insoluble in almost every solvent for ordinary caoutchouc.

Unvulcanized caoutchouc possesses very interesting and peculiar properties. The first part of the present chapter is devoted to this substance. Those who have never seen the crude gum as imported are familiar with the article almost pure in the form of sheet rubber and black rubber articles generally. These are of nearly pure caoutchouc, though recently the tendency is to vulcanize them to a considerable degree.

25

A piece of pure gum containing no combined sulphur, iodine, or other vulcanizing constituent will be found to exhibit a very striking peculiarity. Two freshly cut surfaces when placed in contact will adhere. This is not in consequence of any viscous or sticky coating. When india rubber is cut the surface is perfectly dry and non-adherent except to itself.

The writer once had this property of adhesion brought strongly to his attention. In some analytical investigations of coal gas he had proposed to use finely divided india rubber as an absorbent of sulphur. This constituent it absorbs from gas, and it seemed that a basis for a quantitative determination of sulphur might be found in such property. Accordingly some raw india rubber was procured and with some trouble was cut up into little pieces which were put into a bottle. A day or two afterwards the pieces united wherever they were in contact, and an irregular cavernous lump was the result. This involved no melting or softening or change of shape. Each little piece was there intact and distinct but firmly attached to its neighbors.

The analogy of this action is seen in lead. Two fresh surfaces brought together, preferably with a twisting or wrenching pressure, adhere quite firmly. The adherence of india rubber and of lead each to itself is often exhibited by physical lecturers as an illustration of cohesion. The cohesion of india rubber is however far more perfect than that of26 lead, probably because of its comparatively great resistance to oxidation, and because, owing to its elasticity larger areas can be brought in contact. Comparatively great though this resistance to oxidation is, oxygen, especially in the allotropic modification known as ozone, may act quite powerfully on the gum. Sunlight also can affect it injuriously.

A more familiar illustration of the uniting of two pieces of the same material is seen in the welding of iron. The blacksmith heats two pieces of iron until they are nearly white hot and are pasty in consistency. On placing them in contact and hammering to force them together they unite so firmly as to be practically one. It is necessary that the surfaces of clean metal should be brought together. If the pressure induced by the hammering is insufficient to bring this about, a flux is added which dissolves the oxide and causes the metal to come in contact with metal and to weld. The analogy with india rubber in its cohesive action is evident. Surfaces long exposed or which are dusty do not cohere. The relegation of ice is similar in effect.

The cohesion of india rubber is important and should be thoroughly appreciated. It is not saying too much to assert that the entire treatment of the raw gum depends upon this interesting property. The great lumps of gum are torn to pieces and washed free from gravel and dirt without going to powder, because owing to their elasticity they yield27 and as fast as torn apart the pieces tend to reunite. Again india rubber is mixed with pigments and vulcanizing reagents by a method practically one of grinding or masticating, but the material while it changes its shape, and by the admixture of the various ingredients becomes less strong or easier torn, still remains intact, as it welds together or coheres as fast as disintegrated.

As regards its chemical constitution the sap of a Para rubber tree has been analyzed with the following general results: (Faraday).

| Caoutchouc | 30.70 |

| Albuminous, extractive, and saline matter, etc. | 12.93 |

| Water | 56.37 |

| 100.00 |

Its specific gravity is 1.012.

Caoutchouc itself or raw india rubber is a mixture of several hydrocarbons of the following composition in general:

| Carbon | 87.5 |

| Hydrogen | 12.5 |

| 100.0 |

Its specific gravity is from .912 to .942.

The hydrocarbons composing it are isomeric or polymeric with turpentine. This fact brings it well within the range of familiar vegetable products. As will be seen the products of its distillation fall among the same polymers and isomers.

28

When pure it is nearly colorless, the dark color being due to impurities. In thin sheets it is almost or quite transparent. It burns readily, and with a very luminous, smoky flame, as might have been anticipated from its composition. The action of heat and cold on it is dependent on the degree of the temperature. At ordinary temperature it is elastic and firm. It can be stretched and will return almost to its original size when released from tension. Yet the return to its shape is so liable to be incomplete, especially after long sustained stretching, that pure unvulcanized india rubber is considered imperfectly elastic.

Any elasticity it possesses is principally elasticity of shape as distinguished from elasticity of volume. In other words when pressed or stretched it may change shape to a great extent but hardly change its volume at all. A cube of 2½ inches under a weight of 200 tons lost 1-10 of its volume only. This is largely due to the fact that it represents an approximately solid body, or one destitute of considerable physical pores. Solids and liquids are very slightly compressible. Whatever degree of compressibility caoutchouc possesses is due principally to its minute pores.

If the temperature is reduced to the freezing point of water a piece of raw india rubber becomes rigid and stiff. On application of heat it returns to its former pliable condition. The same return to flexibility may be brought about by stretching it29 mechanically. This may be rather a fallacy. Stretching india rubber warms it, so that in this mechanically imparted rise of temperature we may find at least a probable cause of the softening.

If the temperature is raised several effects are produced, according to circumstances. A piece which has been stretched and held stretched, has its tension increased by a degree of heat considerably less than that of boiling water. Some offer the theory that it contains air enclosed in its pores which, expanding, produces this effect. As the boiling point is reached the material softens and becomes somewhat plastic, so that it can be moulded into shape to a considerable extent and stretched to threads of great fineness. Its elasticity also disappears as the heat is maintained. These effects increase in extent up to a heat of 248° F. (120° C.). The return to its original state is not immediate however. Some time is required before the reduction of temperature will have full effect.

If now a still higher degree of heat is applied, 392° F. (200° C.) the india rubber softens to a viscous body, or melts. From this state it cannot be restored. It remains permanently “burned” or melted whatever is done to it. Some attempt at hardening may be made by the use of vulcanizing chemicals, but the result will be very imperfect.

A further increase of heat brings about a destructive distillation. India rubber treated in a retort to a heat exceeding 400° F. (204° C.) evolves volatile30 hydrocarbons of oily consistency, and it distills almost completely, a small residue of gummy matter or of coke if the final heat has been pushed far enough being left. The distillate is called caoutchoucin. According to Mr. Greville Williams it consists of two polymeric hydrocarbons: one, caoutchin C10H16, boiling point 340° F. (171° C.); the other, isoprene C5H8 (in formula equal to one-half of caoutchin), boiling point 99° F. (37° C.). The mixture has a strong naptha-like odor and has won considerable reputation as being the best solvent for india rubber. How far it deserves its reputation is a matter open to discussion.

The solution of india rubber like its fusion is a vexed point. There is little question that it can be dissolved by proper treatment. Usually naptha, carbon disulphide or benzole are used as solvents, the choice being guided by motives of cheapness and efficiency.

It is worthy of remark that the formula given for caoutchoucin is the same as that of the principal constituent of oil of turpentine, and that the latter is often recommended as a solvent. Turpentine is slightly more volatile than caoutchoucin, its boiling point being 322° F. (161° C.) Other hydrocarbons have been recognized in the distillate by Bouchardat, Himly and G. Williams, varying in boiling point from 32° F. (0° C.) to 599° F. (315° C.), and in specific gravity from 0.630 to 0.921.

Although it has been spoken of as approximately31 solid it does possess microscopic pores, to which its limited amount of elasticity of volume is mostly due. Thus it is found to absorb water, in which it is quite insoluble. As it does this it acts like a dry sponge and increases in volume a little, owing to dilation of these minute pores. The water absorbed may be as much as 18.7 to 26.4 per cent. with an increase of volume of the gum of 15/1000 to 16/1000. When it has once absorbed water it is very hard to get rid of it. Although the minute surface orifices communicate with the entire system of capillary vessels and pores, the surface pores on drying contract and seal up the absorbed water within the mass. This is a clew to the impracticability of the gatherer shipping dry rubber, and to the great difficulty the manufacturer experiences in drying his washed and sheeted stock before working it up by masticating or mixing and curing.

By proper manipulation caoutchouc may be made inelastic. This can be done by the freezing process or by keeping it stretched for two or three weeks. In this way threads can be made to extend and to remain extended to seven or eight times their original length. They can then be woven into a fabric. On gentle heating their original elasticity reappears and they contract. In this way fluted braids can be made which will have a high capacity for stretching.

The solution of caoutchouc is difficult often to bring about. We have seen that in water it swells32 a little without dissolving. In benzole it does the same, but swells to a greater extent, to 125 times its original volume or even more. Some authorities (Watts) go so far as to assert that no solvent completely dissolves it. Acting on it repeatedly with benzole or other solvent and taking care not to break up the swelled mass, from 49 to 60 per cent. of soluble matter can be extracted. On evaporation this is deposited as a ductile adherent film. The swelled up residue which remains undissolved is assumed to be the constituent giving strength and elasticity, and is only sparingly soluble. If the gum is masticated or kneaded at the temperature of boiling water a change occurs not well understood, by which its solubility is greatly increased. As solvents many liquids have been named. Oil of turpentine, caoutchoucin, coal-tar, naptha, benzole, petroleum-naptha, coal-tar-naptha, anhydrous ether, many essential oils, chloroform, bisulphide of carbon, pure, or mixed with seven or eight per cent. of alcohol, are among the solvents recommended. A mixture of fifty parts of benzole and seventy parts of rectified turpentine has been given as a solvent for twenty-six parts of the gum. Mastication before or after immersion in the solvent is to be advised. More will be said on this subject in a succeeding chapter.

Vulcanized india rubber is unaffected by changes of temperature within ordinary range. It softens a little on heating. Even hard vulcanite when heated33 can be bent and will retain the bend on cooling. It is exceedingly elastic with elasticity of shape but far less compressible as regards absolute change of volume than the raw gum. It melts at 392° F. (200° C.) It cannot be made to cohere, and no cement has yet been discovered that will satisfactorily unite two surfaces. It is unaffected by light, by ordinary acids and rubber solvents. In contact with the latter solvents it swells sometimes to nine times its original volume, but on heating returns to its original volume and shape. Of water it will absorb no more than four per cent. and often much less. If it is maintained at a high temperature 266° to 302° F. (130° to 150° C.) for a long time it gradually loses its flexibility, especially if in contact with metals. Often the escape of sulphuretted hydrogen may be observed under these conditions. A small admixture of coal tar operates to prevent this action.

Its composition and specific gravity vary widely as the most varied mixtures are added by the manufacturer. Its relation of carbon to hydrogen is unaffected by the mixtures added. While it may contain twenty per cent. or more of sulphur it is believed that but a very small quantity is combined with it, although the excess of sulphur or some equivalent, such as sulphide of antimony is essential to vulcanization. The combined sulphur is from one to two per cent. Some or all of the excess of sulphur is mechanically retained, and as the34 rubber in ordinary use is worked about, keeps escaping and forms a whitish dust upon the surface. By treatment with alkali some of the excess of sulphur can be removed when the rubber acquires the power of absorbing a little more water, up to six and four-tenths per cent.

Boiling oil of turpentine is given as its solvent.

35

The manufacture of india rubber relates to the production of two principal products. One is masticated unvulcanized sheet and thread rubber; the other is unmasticated mixed and cured rubber, otherwise vulcanized rubber. For the purposes of the rubber-stamp maker an intermediate product is required, namely, unmasticated mixed sheet which is uncured. This is really incompletely vulcanized india rubber.

It will be evident from the description to come that it is not advisable for any one without considerable apparatus to attempt to clean and to wash (“to sheet”), to masticate, or to mix india rubber. These operations are best accomplished in the factories. The partially vulcanized (“mixed sheet”) or the pure masticated article are regular articles of commerce. Yet a full insight into the manipulation of india rubber can only be obtained by understanding its treatment from the gum up to the two separate lines of products we have indicated.

A third type of product is coated tissue, such as36 Mackintosh. This really is a sequence of one of the other two processes and a few words will be said of it in concluding the chapter.

As the caoutchouc is received by the manufacturer it appears an utterly intractable mass. It occurs in lumps of every size, varying in color and odor, and very tough but elastic. In virtue however of the properties already described, its power of cohering when cut, and its softening when heated, it becomes amenable to treatment.

It is to some extent received in such assorted condition as to secure even grades, and then each grade may be washed by itself. It is thrown into water which is in many cases kept at the boiling point by steam-heat and left there for some hours. It absorbs some water and also softens. Some gum is so soft that it will not stand hot water. For such the water is kept cold. The purer gum floats; such pieces as have stones, dirt, iron, etc. in them, perhaps placed there purposely from fraudulent motives, sink and can be picked out for separate treatment.

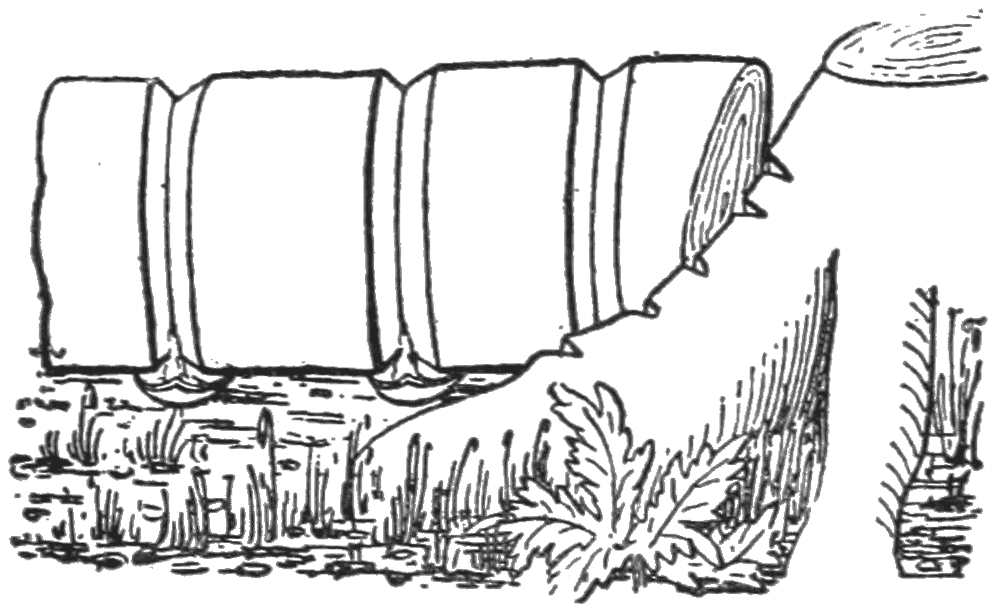

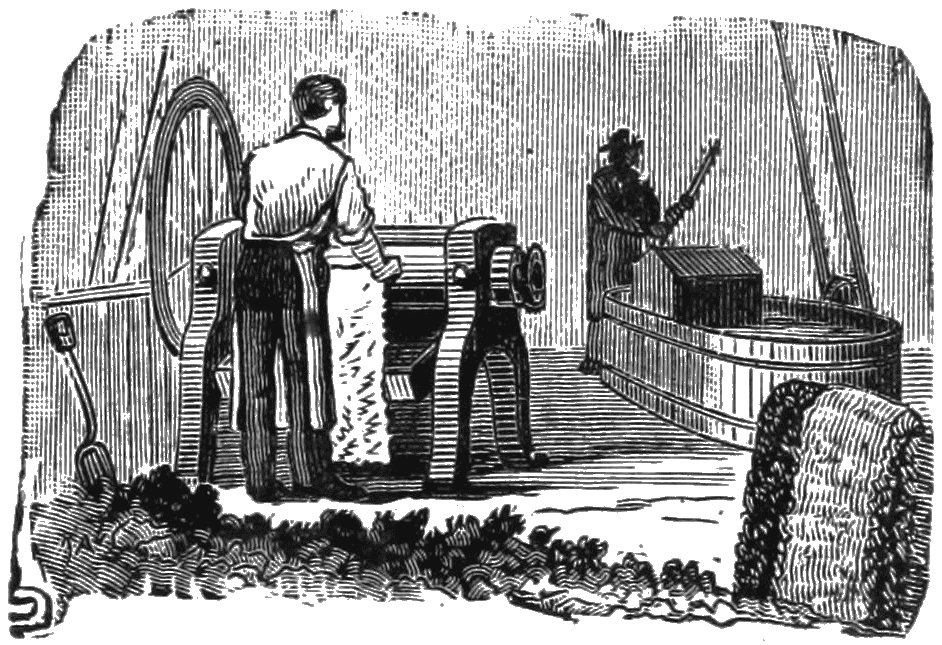

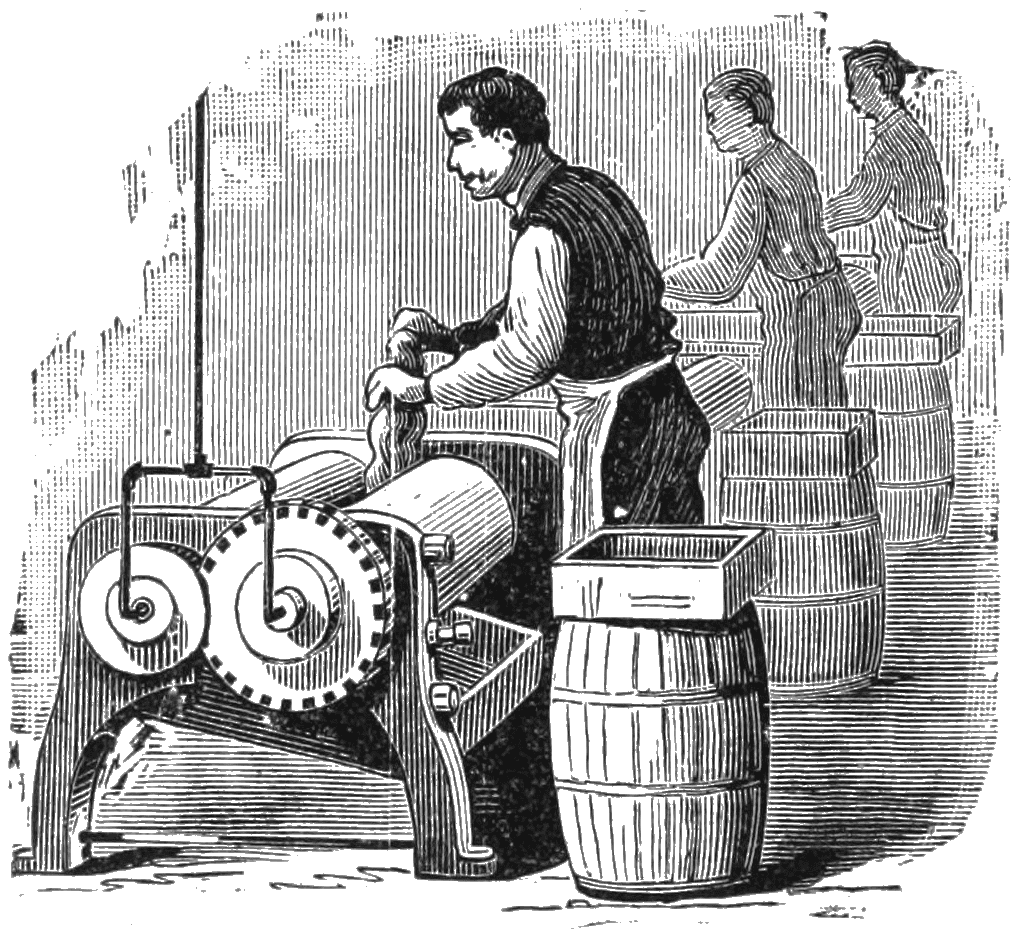

The lumps are next cut up. A revolving circular knife driven by power is often used, and sometimes an ordinary knife is adopted. At this part of the operation there is frequently need for sorting, as the grades received may have inferior pieces mixed with the good. The cutting is mainly to secure good grading, and to remove concealed impurities. The gum then goes to the washing rollers, called the washer and sheeter. (See cut, p. 37.)

37

These are heavy corrugated rolls made very short, 9–18 inches in length, to prevent springing. They are grooved or corrugated and have a screw adjustment for regulating their distance apart. They are geared together so as to work in corresponding directions, like a clothes wringer or a rolling mill of any kind. The pieces of gum are fed into the rolls and are drawn between and through them. The friction tends to heat the gum. To prevent this and also to effect the washing, a supply of water, either hot or cold, is kept playing upon the mass. This dissolves out all soluble matter and washes away mechanically the chips, dirt, etc. which may be present. The whole operation is one of main force. The caoutchouc is torn and distended and delivered as a rough perforated sheet. It is passed repeatedly through the machine, the rollers being gradually brought closer together, or else different sets of rolls are used, set to different38 degrees of fineness. The wash water passes through a screen which catches any small detached fragments of gum.

Other types of machines have been introduced; the above is a representative form.

The rough sheets must now be perfectly dried, as water impairs the final product. This is done in drying rooms by steam heat, generally, at a temperature of about 90° F. (32° C.) The windows, if there are any, are painted to exclude sunlight, which operates to deteriorate raw gum. When absolutely dry the caoutchouc is removed and stacked away for use.

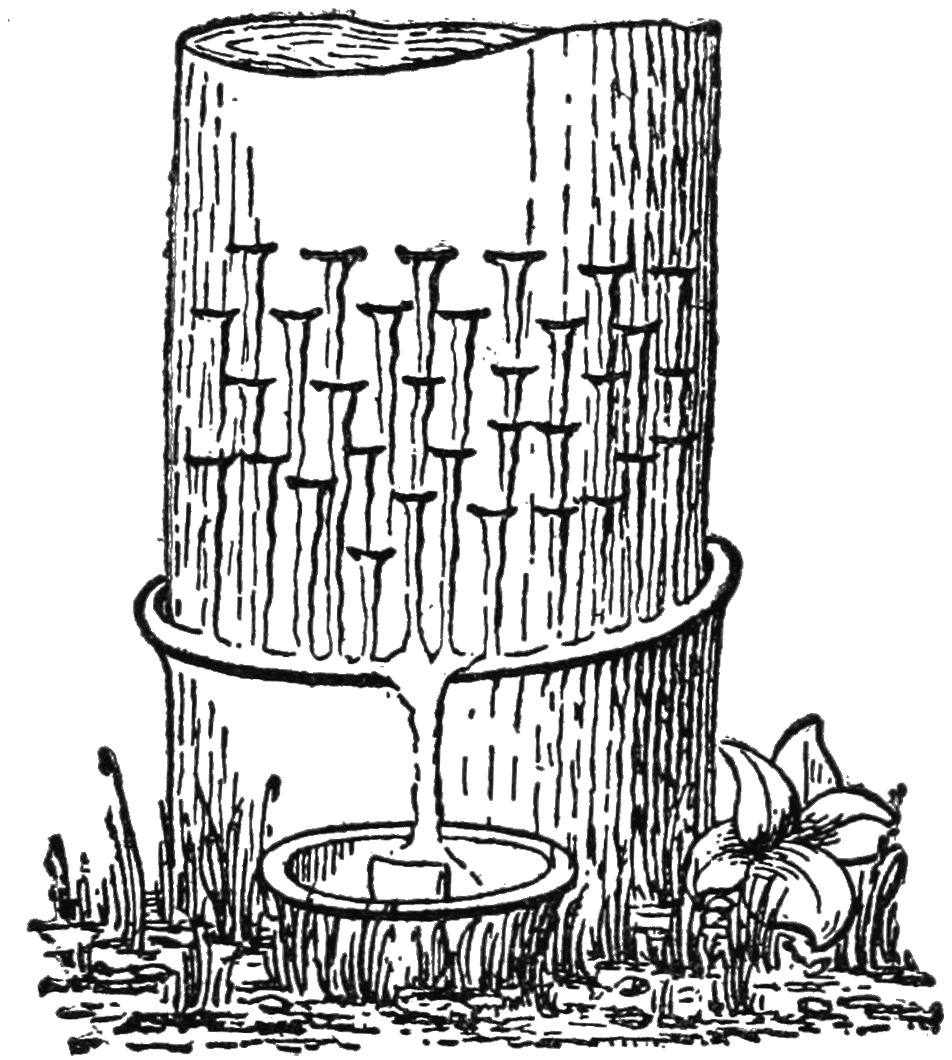

To prepare pure gum for the manufacture of sheet rubber and as a starting point for many other preparations, the india rubber is “masticated” in39 special apparatus. The machine consists of a fixed cylinder within which is a corrugated roller set eccentrically and rotated by power. The perfectly dry sheets in the masticator are pressed and rolled and ground and produce a mass of even consistency. Here the welding or cohering action again appears in its fullest development. The perfect dryness of the mass enables it to keep reuniting as fast as divided. The action is assisted by the heat generated, which is not inconsiderable. Sometimes the caoutchouc is warmed before introduction, and sometimes the roller is heated by passing steam through it.

The masticating machine the French picturesquely term the wolf (loup) or devil (diable). It is given from sixty to one hundred turns a minute, and a machine large enough to treat fifty pounds of40 gum in a charge, requires five horse-power to drive it. In it the sheeted gum is ultimately brought to the state of a perfectly homogeneous dark brown translucent mass.

The masticated rubber is peculiarly amenable to mechanical and chemical treatment. It can be shaped by heat and pressure, and it is the most soluble form and is used for making cement and solution, and is moulded into blocks for the manufacture of sheet and thread rubber. In the process neutral body pigments, such as oxide of zinc, or soluble transparent ones, such as alkanine may be introduced; easily decomposed matter cannot be incorporated on account of the heat.

In all these machines special provision is made to prevent any oil from getting into the gum. There is no greater enemy to india rubber than oil or fats of any description. The flanges in the masticator that roll just inside the bearing are for this purpose.

Sheet rubber is made from the blocks of masticated gum by slicing. A machine is used for the purpose which carries a knife which works back and forth in the direction of its length at high speed, making two thousand cuts a minute. The knife is kept wet by a stream of water, and about sixty cuts are made per inch. In many articles made from this sheet the marks of the cuts can be seen as a fine ribbing. The appearance is familiar to many readers.

41

The sheet is often cut from rectangular blocks, but cylindrical blocks are also used. The latter are rotated in front of the knife edge and a long, continuous sheet can thus be obtained.

The sheet rubber can be cut into threads on webbing and braid. Everyone has noticed that these threads are usually square. The method of preparation accounts for it. Vulcanized sheet is now almost universally used for threads.

Round threads however can be made by forcing softened or partly dissolved gum through a die.

It is from unvulcanized masticated sheet that toy balloons, tobacco pouches, etc., are made. It is the starting point for india rubber bands. For the usual form of the latter article the sheet is cemented into a long tube which is afterwards cut transversely, giving bands of any desired width. To make any of these articles satisfactory vulcanization is imperative. Unvulcanized rubber for many years was used, but it is now completely displaced by the vulcanized product. Sheet rubber is made as above; is vulcanized by some of the absorption processes described in the chapter on vulcanization.

We now come to the second product: regularly mixed and cured rubber. Its starting point is the washed india rubber from the washer and sheeter.

We have seen that the pure gum or caoutchouc is very sensitive to changes of temperature. At the freezing point of water it is hard and rigid, and at42 the boiling point is like putty in consistency. There are several substances which can be made to combine with the gum and which remove from it this susceptibility to change of temperature. The process of effecting this combination is called vulcanization, and the product is called vulcanized india rubber. Sulphur is the agent most generally employed.

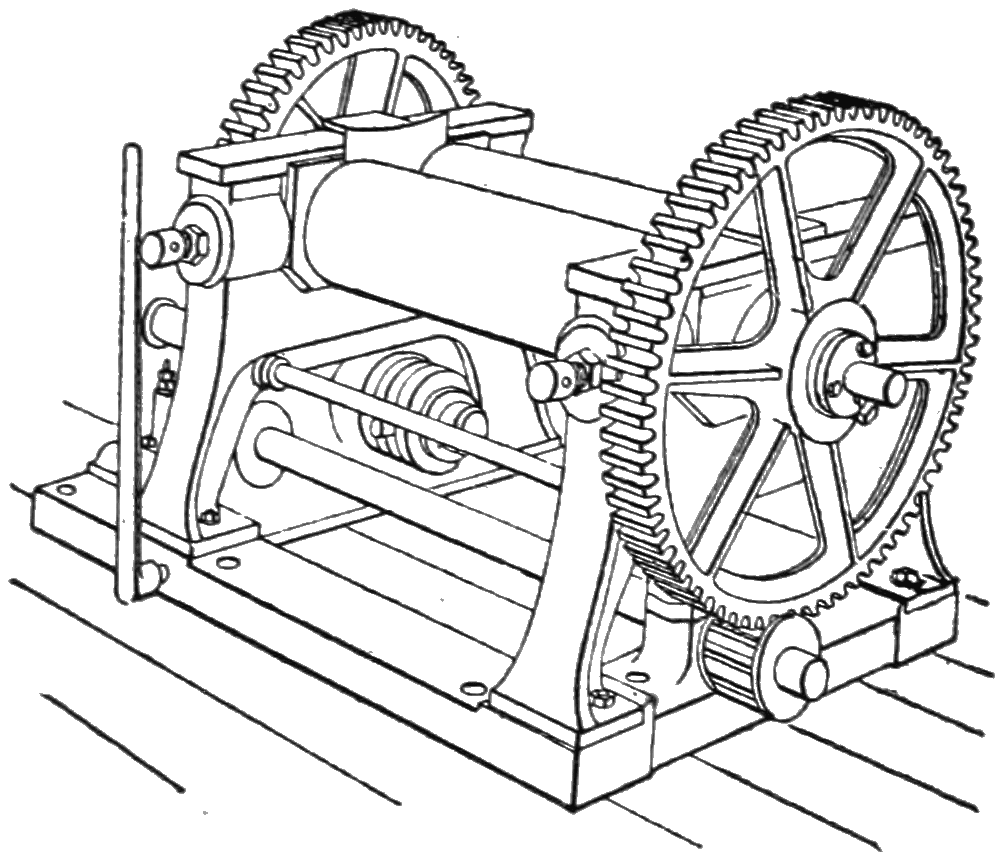

In the factory the normal vulcanization is carried out in two steps, mixing and curing. The washed sheet india rubber which has not been masticated and which must be perfectly dry is the starting point, and the mixing rolls shown in the cuts are the mechanism for carrying out the first step. These are a pair of powerful rollers which are geared so as to work like ordinary rolls, except that one revolves43 about three times as fast as the other. They are heated by steam, which is introduced inside of them. The sheet is first passed through them a few times to secure its softness, and then the operative begins to sprinkle sulphur upon it as it enters the rolls. This is continued, the rubber passing and repassing until perfect incorporation is secured. About ten per cent. of sulphur is added, and a workman can take care of thirty pounds at a time.

This material is incompletely vulcanized. It is in its present condition very amenable to heat and is ready for any moulding process. Generally it is rolled out or “calendered” into sheets of different thickness from which articles are made in moulds by curing.

These sheets are of especial interest to the reader as they are the material from which most small articles are made, including rubber stamps.

This rolling of the mixed india rubber into sheets of definite thickness is done by special calendering rolls. The product is termed “mixed sheet.”

In the mixing rolls the incorporation of other material is often brought about. Zinc white, lead sulphide, antimony sulphide, chalk, clay, talc, barium sulphate, plaster of paris, zinc sulphide, lead sulphate, white lead, oxides of lead, magnesia, silica, form a list of ordinary mixing ingredients. These lower the cost of the finished material and are often serious adulterants. For some cases the addition if not carried too far is not injurious, or even44 may be beneficial. A proper admixture renders the gum more easily moulded and treated in the shaping processes.

The next step in the vulcanizing process is the heating of the mass, which step is called “curing.” Up to a temperature in the neighborhood of that of boiling water the mixed rubber can be heated without change except as it is softened. But if the heat is increased it begins to get a little more elastic and less doughy, and eventually becomes “cured” or vulcanized. The temperature for vulcanization is about 284° F. (140° C.). The word “about” is used advisedly, for it is not only a question of heat but of time of exposure. After vulcanizing, including the curing, india rubber cannot be moulded to any great extent. In the manufacturing process, therefore, it is before curing placed in the moulds,45 heated, shaped by pressure, and by exposure to a higher heat in a steam oven called a vulcanizer, is at once cured.

To prevent adherence to the moulds they are dusted over with ground soapstone, and the rubber itself is often thus coated.

The methods of vulcanization and curing, which may be of special use to the reader, are given in the chapters devoted to that subject (chapter XI.), and in the one devoted to rubber stamps.

Hard rubber, termed ebonite when black, and vulcanite when of other colors, is simply vulcanized rubber containing a large percentage of sulphur added in the mixing process.

The manufacture of coated tissues is effected in several ways. The following is a typical process. A mixture of one part washed and sheeted india rubber with one part zinc white, one fourth part sulphur, and about one third part naptha is mixed into a dough-like mass and is spread upon the cloth by machinery. The latter is simple. It consists of a bare board arranged to move under a scraping bar. The cloth is placed on the board and carried under the bar. The coating mixture is fed on one side of the bar upon the surface of the cloth. As it passes under, a regulated amount, according to the set of the bar, adheres. It is then dried by steam heat and recoated, until ordinarily six coats, each about one one-hundredth of an inch in thickness, have been given. Three coats are given in each direction with46 intermediate drying. The fabric is then cured by heat in vulcanizers.

Sometimes the sulphur is omitted from the mixture and cold curing, as described later, is adopted. When the goods are made up the seams are secured with rubber cement, a thick solution of masticated gum. Such seams have to be vulcanized.

Sometimes two such fabrics before curing or vulcanization, are placed face to face and allowed to adhere and are then cured or vulcanized.

Enough has been said in this outline of the manufacturer’s treatment of india rubber to show that the first treatment requires machinery. Very little can be done with mortar and pestle, although in making up solution these simple instrumentalities are available. As a starting point for making small articles masticated sheet rubber and mixed sheet rubber are the staple materials. The preceding steps are best accomplished in the factory.

47

We have seen that india rubber cannot be cast in moulds. Except in special cases deposition from solution is not available. It has to be shaped by a combination of heat and pressure. When gently heated it softens and can be pressed in a mould. As it cools it retains the shape thus given and is moulded. This applies to all unvulcanized india rubber. If mixed rubber is moulded and heated to a higher temperature without removal from the mould the curing process is brought about and the rubber may be not only moulded but cured and the product is moulded vulcanized india rubber. The mixed sheet whose manufacture is described in chapter IV. (page 42) is the starting point in rubber stamp making. It is made for this purpose by the manufacturers.

When the material is examined it looks like ordinary white india rubber, being firm in texture and quite strong. On heating to 280° F. to 290° F. (137° C. to 143° C.) it begins to become “cured,” and if in a thin sheet one to ten minutes are sufficient for the process. As the heat is applied the india48 rubber first softens and becomes much like putty. It can now be pressed through the smallest orifice and will fill up the finest details of anything it is pressed against. It is at this point that pressure must be applied to drive it into the interstices of the mould.

As the heat continues it begins to lose its doughy or putty-like consistency. This marks the reaction of the vulcanizing materials. They gradually combine with and change the nature of the caoutchouc. The rubber while still quite soft is elastic. If pressed by the point of a knife it yields, but springs back to its shape when released from pressure. The india rubber is vulcanized.

On removal from the mould it will be found to reproduce its smallest detail. The color and appearance have not changed much, but its nature and properties are now those of vulcanized rubber. It is unaffected by heat or cold within ordinary ranges of temperature, and if the india rubber is of good quality and made by a proper formula it will last for years.

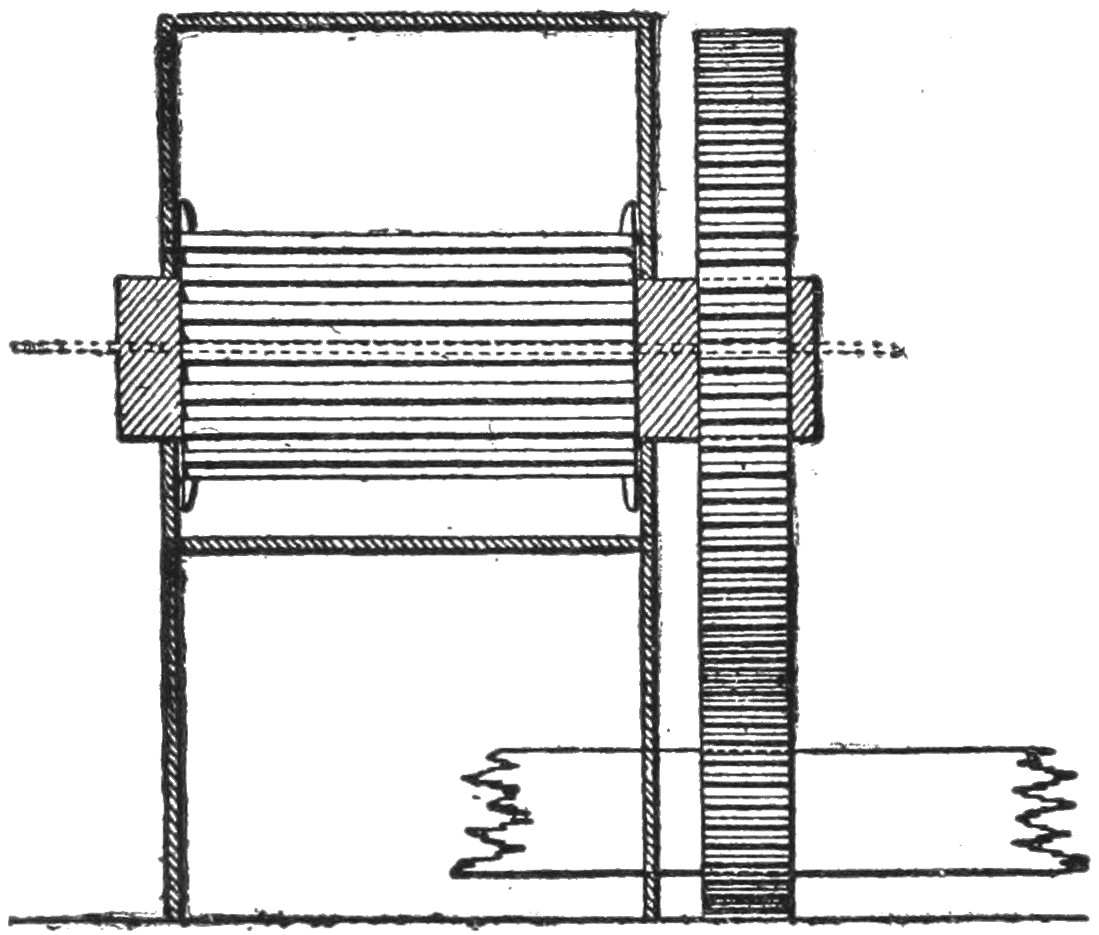

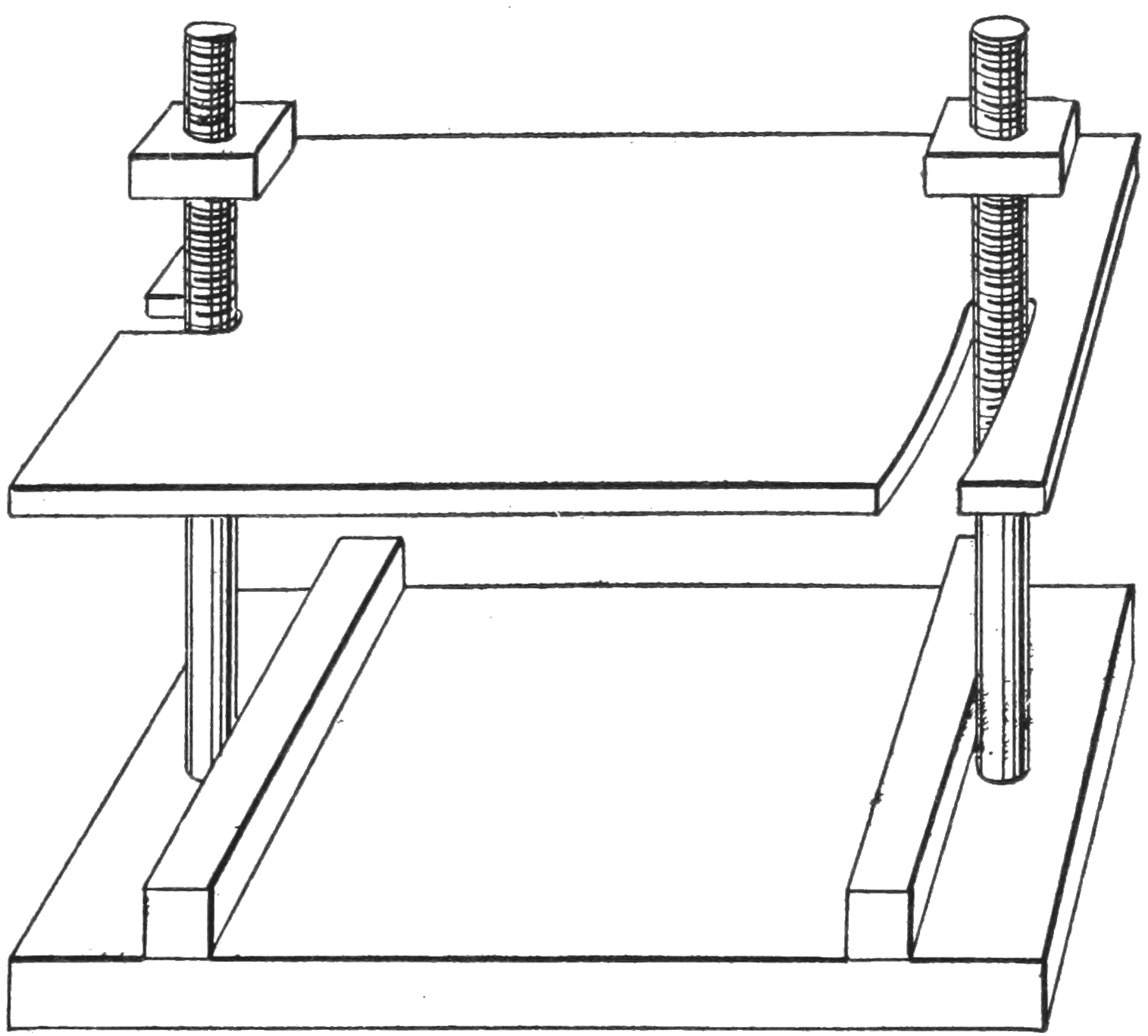

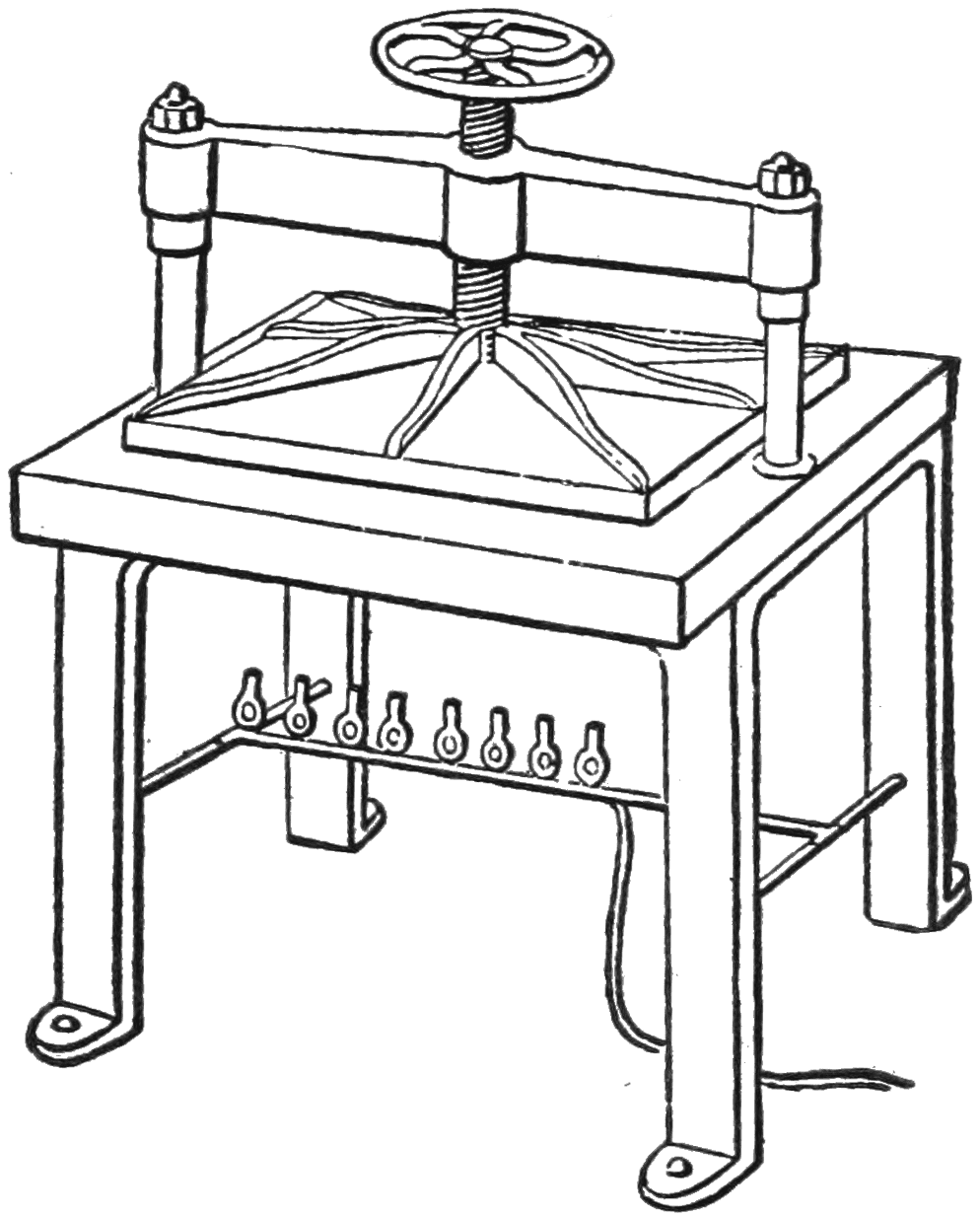

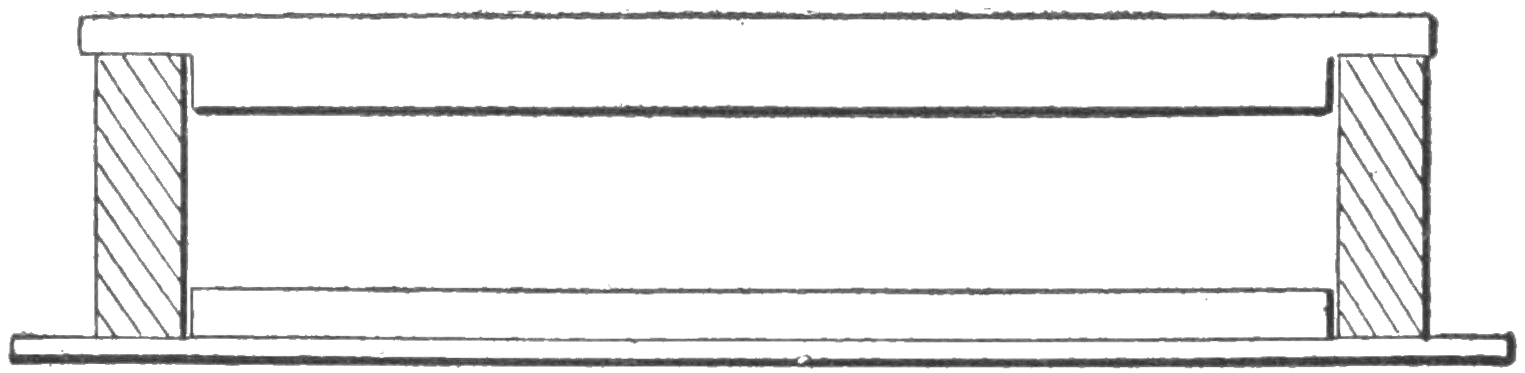

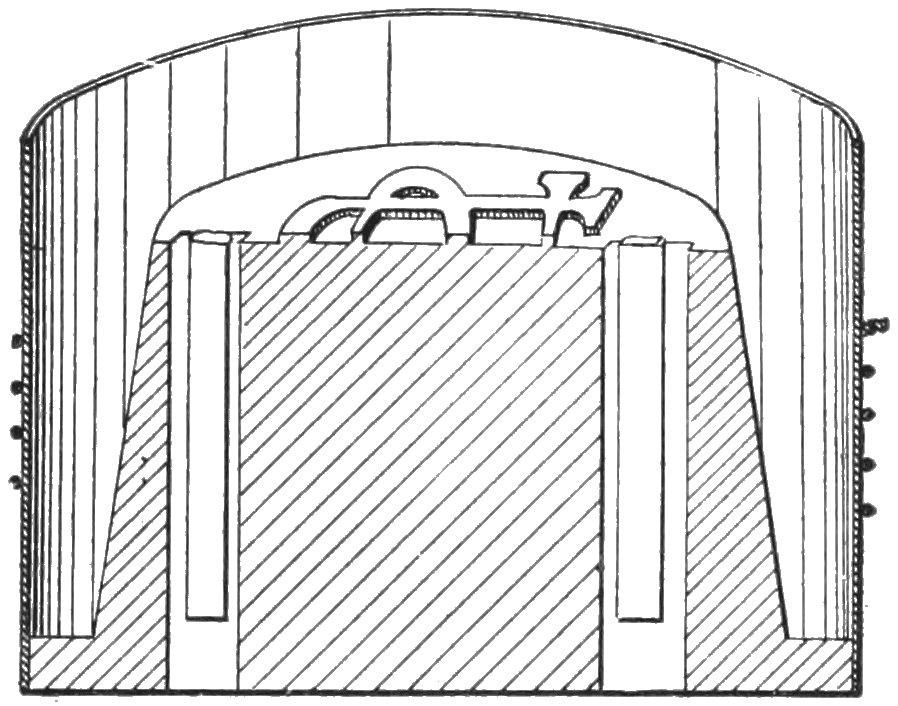

The first thing to be described is the mould, which includes the arrangements for pressing the sheet of india rubber while heated. A small press is needed for this purpose. It may be of the simplest description, and as an example of a home-made but perfectly efficient one the illustration may be referred to. The base of the press is a piece of iron, if heat is to be directly employed. Where a49 chamber vulcanizer is used both base and platen may be of wood. But from every point of view iron is the best. It lasts forever, admits of direct heating, and does not split, warp, or char. Through two holes drilled near its opposite sides two ordinary bolts are thrust. It is best to use flat headed bolts, and to countersink a recess for the heads in order to keep the bottom level. The heads may need to be filed off so as to reduce their thickness, in order to secure this object. The bolts may be soldered in place. One thing should be carefully50 watched for—the bolts should be set true so as to rise vertically from the plane of the base.

The platen is best made of iron, cut of the shape shown. This is an excellent disposition of the screw-bolt slots, as by swinging the right end of the platen back it can be taken off without removing the nuts and lifting it over the ends of the screws. Besides the two nuts fitting the thread of the screws it is well to have half a dozen extra ones larger than the others, which will slip easily over the bolts, so as to act as washers. The object of these is to adapt the press to objects of different thickness. The thread upon an ordinary bolt does not extend clear to the head, but by slipping on some loose nuts the plates can be forced together if desired.

This press can be simplified. Both base and platen can be made of wood, the platen being simply bored for the bolts, and the latter driven tightly through the holes in the base so as to retain their place. Even this can be improved on as regards simplicity. Two blocks of wood screwed together by two or more long wood screws may be made to do efficient work.

One trouble is apparent with all these devices, and that is the want of parallelism of the opposed planes. The base and platen may be true and parallel or they may not. Perhaps the simplest way of securing this is the best. It consists in placing across the base two distance pieces, which may be slips of wood. These must have perfectly51 parallel faces. As the press is screwed up they will be gripped between the platen and base and will not only ensure their parallelism but will keep them at an exact distance apart. Such distance pieces are shown in the same cut. Pieces of printers’ “furniture,” spaces, or “quads,” may be used for this purpose. They should not be fastened in place if there is need to adapt the press to more than one thickness of material and matrix.

The above described apparatus is a vulcanizing press. A further improvement in it may be effected by the use of spring pressure. Two strong spiral springs may be dropped over the bolts, the nuts being screwed on above them, or a powerful spring of flat brass or steel ribband bent into the shape of a shallow letter V may intervene between nuts and platen, the centre of the bend bearing against the centre of the platen.

As regards the strength of the springs there is this to be said. The distance pieces will prevent a spring that would ordinarily be too powerful from doing any harm. Such distance pieces should be used, as the springs must be based upon giving a pressure of many pounds per square inch of surface to be acted on. They should have a range of an eighth of an inch or more. The greater the range the more evenly will they work.

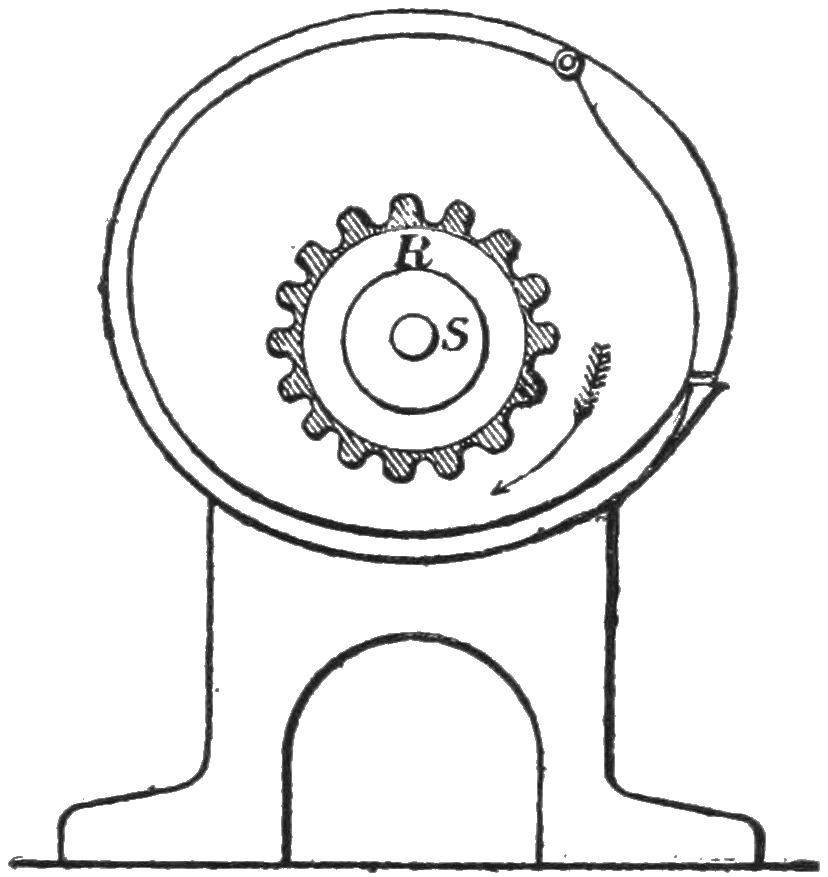

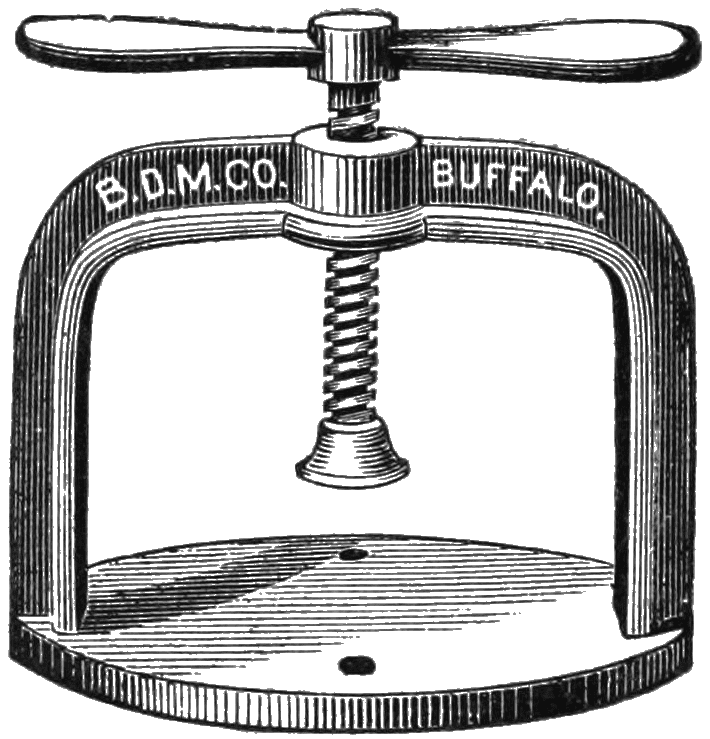

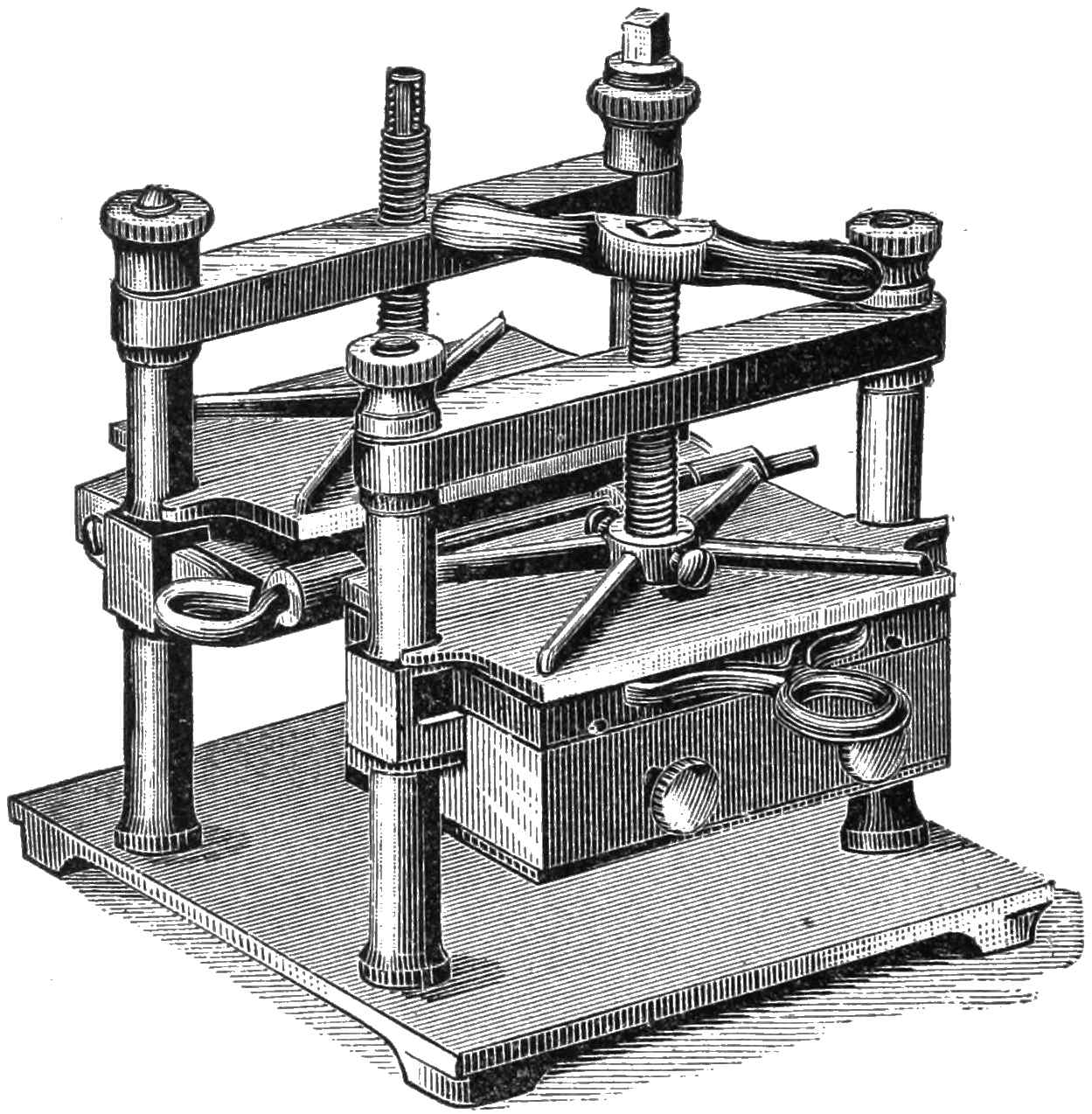

The next cut shows an excellent little screw press, that is made for the purpose of pressing vulcanizing flasks. This is so simple that it will suggest to the52 mechanical reader how he can make a single-screw press, which is by far the most convenient to use. In the stationery stores very small model cast iron copying presses designed for use as paper weights are sold. They are excellent for a limited amount of small sized work.

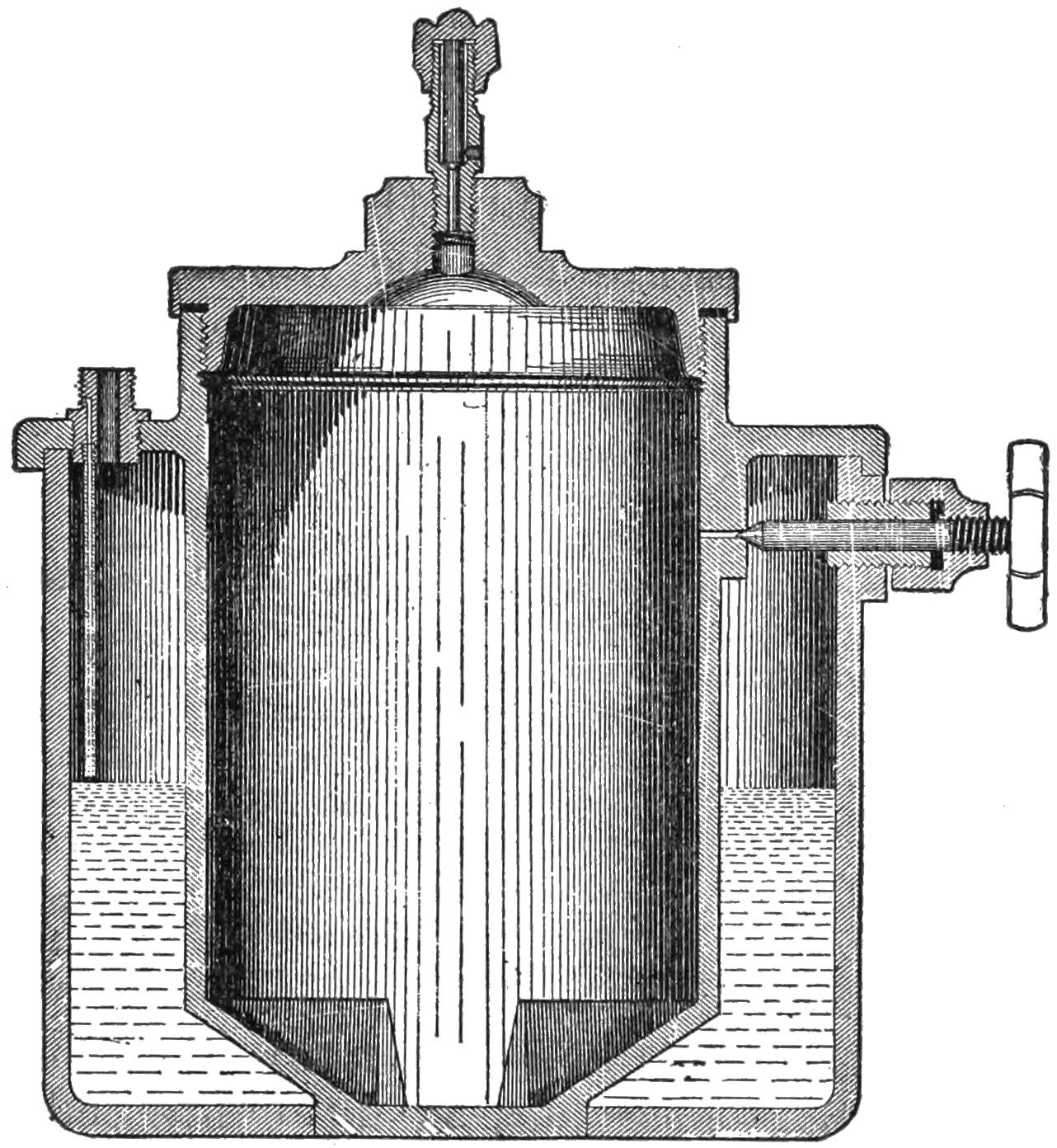

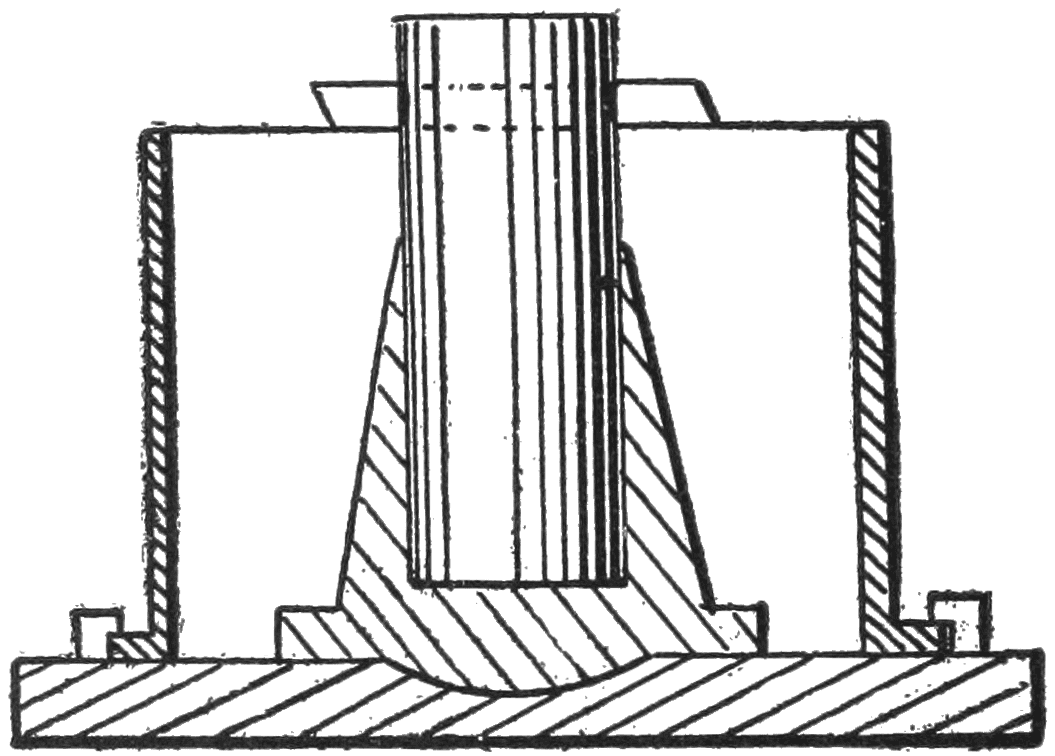

A large sized gas heated press, such as made for the purpose of manufacturing rubber stamps, is shown in the next cut, p. 53. Its construction is obvious. It is termed by the trade a vulcanizer. Its manipulation will be given further on.

Type are generally the object to be copied. These are best set up with high quads and spaces. Naturally rather a large type is chosen, with extra wide spaces between the letters. Some advise rubbing the type faces full of hard soap, afterwards brushing off the face, leaving the hollows filled. Sometimes wax is recommended for the same purpose.53 This prevents the plaster of the matrix entering so deeply into the cavities of the letters.

The type forming the model to be reproduced, is locked in a frame. Two pieces of printers’ furniture or other wooden strips screwed together by wood screws at their ends will answer for a locking frame for small inscriptions.

The model to be copied need not be type, but any desired relief may be used, such as an electrotype, a stereotype, an engraving or another rubber stamp. In any case it is to be placed upon a flat surface, best an “imposing stone” or piece of marble, with54 the inscription upwards. On each side of it distance pieces reaching about one-eighth inch above its upper surface are to be placed.

The next shaping appliance is the matrix or mould, or reverse of the model which is to be copied. This in the case of rubber stamps is properly called the matrix. Those who have witnessed the stereotyping of a large daily newspaper have seen the matrices of the type made of paper and paste, the whole mixture being termed “flong.” Such a matrix is required for rubber type, but paper is rather too susceptible to heat although good work can be done with it. It also does not enter as deeply into the cavities of the type as is desirable. As a rule a fine quality of plaster of paris is to be recommended. What is sold as dental plaster is the best, but common plaster can be used. It is mixed with water or with a solution of gum arabic or dextrine in water. For the latter enough gum should be added to make the mixing solution as thick as thin syrup.

A piece of iron, perfectly flat and true, is now to be taken, large enough to more than cover the inscription to be copied. Upon its surface a putty made of the plaster and the liquid used in mixing is to be spread. This should be rather stiff. The surface of the iron should not be too smooth as it is desirable that the plaster should adhere well on setting. The plaster should be smoothly spread to a depth of three-sixteenths or a quarter of an inch.55 It is best applied with a palette knife or trowel, although a table knife will answer perfectly. If its surface does not become smooth it can be made so by applying a little of the solution with the knife or trowel.

Before this has been done the model must be oiled. Olive oil or other clear oil is applied to all parts of the type faces, and the excess is then wiped off and cleared out of the interstices with a piece of blotting paper.

Next the plate with the plaster is inverted and is pressed steadily down upon the model until it strikes the distance pieces. It is left to set. In about ten minutes it can be raised, when it will be found to give a beautiful impression true to the smallest detail of each letter.

It has been said that water may be used as the mixing fluid. If this is done it is well to strengthen the mould by saturating it with an alcoholic solution of shellac, after it has dried thoroughly, best for a few hours in an oven. This operates to strengthen the small projections that are liable to crumble or to break off in use.

The dealers in rubber stamp supplies sell a lever press for conducting the operation of producing the matrix. The type is locked in a special chase, which is carried on a bed that travels under and out from under the platen of the press upon rollers. From each corner of the chase in which the type model is locked, a pin rises which is encircled by a56 spiral spring. A square frame of flat iron with holes at the corners for the pins to pass through, rests upon these springs well above the type. The pins pass through holes in its corners. The matrix plate with its coating of plaster is placed upon this frame, which supports it above and not touching the type. The whole is now rolled under the press and the lever pulled to produce the impression. As the pressure is released the frame with the matrix is raised from the type by the action of the springs. This can be done immediately, and before the plaster has set. It is almost impossible to raise it by hand with the requisite steadiness. The same chase with corner pins and springs can be used in a screw press, the one press answering for making the matrix and for moulding and curing the stamps. The plaster matrix can also be made by casting from a thinner mixture of plaster and water. After the type has been set up, or the model has been selected and placed face up and horizontal, a little ridge or projection must be made all around it. Paper can be pasted around it, and wound with thread for this purpose. It is oiled and wiped off as before. The plaster is now mixed with water to the consistency of cream, and is poured upon the model until it lies even with the projecting ledges or paper border. In an hour or less it can be removed. If water is used the mould should before use be treated with shellac solution as already described. The plaster may also be mixed57 with gum arabic solution, or with three to ten per cent. of powdered marshmallow root. This increases its toughness.

What is known as the oxychloride of zinc cement appears to the author to be far preferable to common plaster of paris. It is a trifle more expensive, but it costs so little that it is well worth trying. It is made by mixing oxide of zinc with a solution of zinc chloride. No particular strength of solution or proportions are prescribed; the zinc chloride solution should be a strong one, and the mixture should be of about the consistency of soft putty.

Zinc chloride may be bought as a solid substance or in strong solution. The latter answers for the mixing directly. It may also be simply made by dissolving metallic zinc in strong hydrochloric acid. The manipulation is exactly the same as with plaster of paris.

The manufacture of papier maché and of other matrices is given in a special chapter. For all ordinary purposes the plaster or cement matrices are ample.

The stamp is made from the mixed uncured sheet rubber, whose preparation in the factory, including the operation of calendering it into sheets, has already been described. The best advice the reader can be given is not to attempt to make it except as a matter of interest and experiment. It can be purchased especially prepared for stamps from the dealers in india rubber.

58

A piece is cut from the sheet large enough to cover the face of the matrix. It should have a perfectly smooth surface, without cloth wrapper marks sometimes found impressed on it. The sheet as received from the maker is about one-eighth of an inch thick. It is thrown into a box of powdered soapstone or talc to secure a coating of the same on both sides. A little is dusted over the matrix and the excess is blown off. The matrix is now placed upon the base of the press, and heat is applied.

To carry out the process most simply the press if of metal may be placed upon a support over a gas burner or kerosene lamp, or even on a kitchen range or stove. It will in a few minutes become warm. The sheet of india rubber is now dusted off and is placed in the press upon the matrix. The platen of the press is screwed down upon it.

As the india rubber becomes hot it begins to soften and flow. By the action of the screw of the press it must be forced down from time to time as it softens. This drives the putty-like material into all the interstices of the mould. The excess escapes from the sides of the tympan in cases where the latter is of restricted area. The press theoretically should be heated to the vulcanizing temperature, which is 284° F. (140° C.). In practice the heat is not determined with a thermometer. The operator learns by experience how much heat to apply. The regulation type of gas heated press or stamp vulcanizer is shown in the illustration on page 53.

59

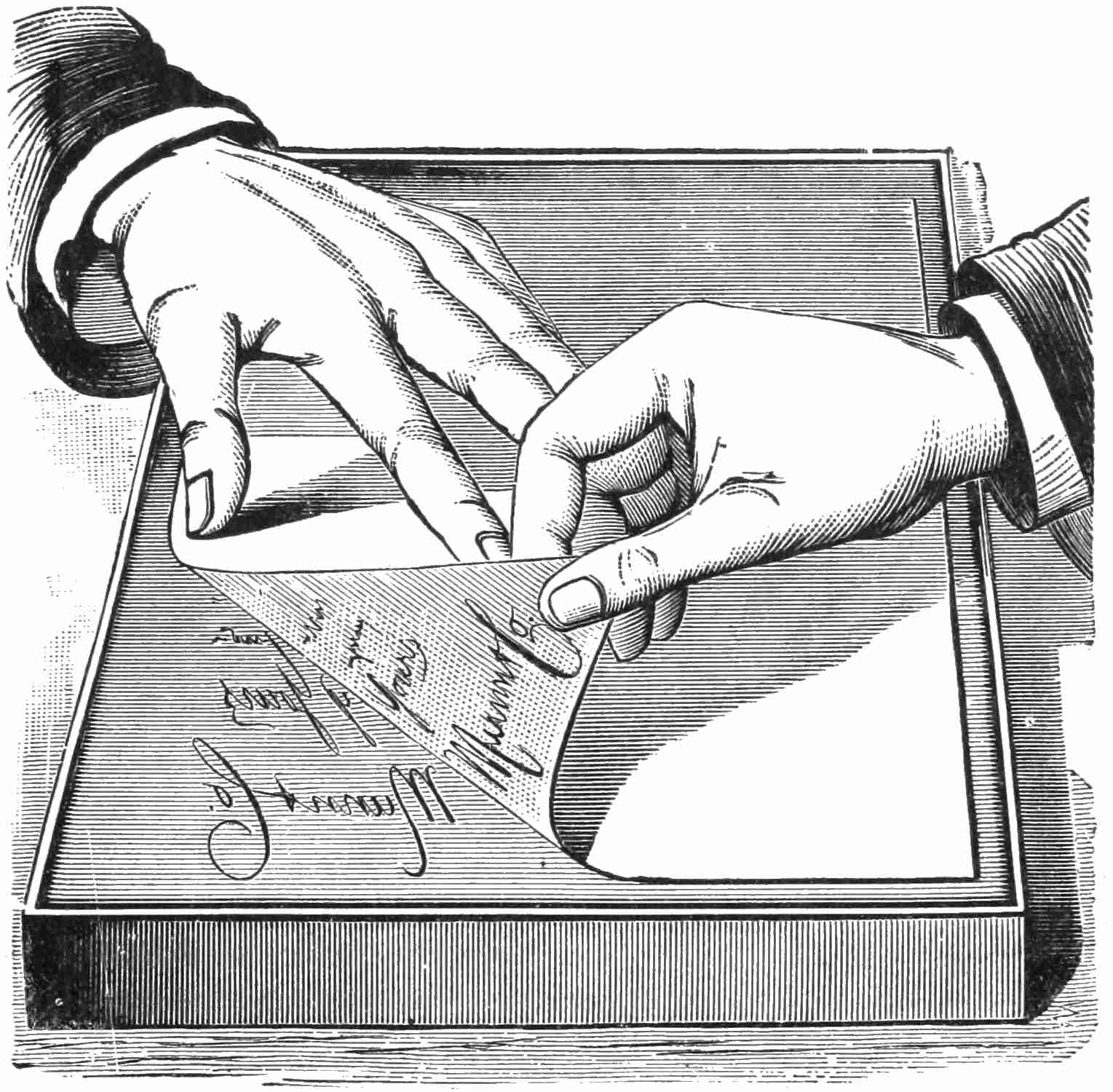

As some of the india rubber is sure to protrude, the progress of the work can be watched from its action. By pressing the point of a knife against it the period of vulcanization can be told. Before the material is heated it is elastic and resists the pressure of the knife; as heat is applied it becomes soft like putty; as the heat increases it again stiffens and becomes quite elastic. At this point the press can be opened and the sheet and matrix can be taken out or the platen swung aside. On pulling or stripping the sheet from the matrix it will be found to reproduce the model in elastic india rubber to the minutest detail.

As regards the minor details there is something60 to be said. Distance pieces to gauge the thickness have been recommended for the home-made press, page 48. Care must be taken to have these low enough to provide for enough excess of material to produce a good impression. For ordinary stamp work they should allow about one-sixteenth of an inch for the “squeeze.” It will be seen that by using the distance or gauge pieces both for making the matrix and for moulding and curing the stamp, absolute parallelism of surfaces will be secured.

The reader will have noticed in the description and will find at once in practice that the press has to be screwed up as the rubber softens. Where heavy iron presses are used the large mass of heated iron comprised in the platen of the press instantly heats the upper surface of the india rubber sheet and the heat immediately penetrates into it, while the heated matrix heats it from below. Thus it softens at once, and the press is directly turned down and the india rubber is driven into the mould and curing at once begins. But where small presses are used this manipulation is not so easy. For such the springs mentioned on page 51, are highly to be recommended. The matrix and india rubber can be put into the cold press, and the tympan with intervening springs can be screwed down so as to compress them. Then on applying heat the moulding takes place automatically.

With a hot press and good sheet a period of three to ten minutes is ample for moulding and curing.

61

Instead of sprinkling with talc the matrix may be oiled and sprinkled with plumbago and afterwards polished with a brush. This is not so clean a material as talc and is not to be recommended for general use, especially as oil is a bad substance to bring in contact with rubber.

The distance or gauge pieces whose use has been recommended are not necessary where presses working truly parallel as regards their opposing faces are used. But where home-made apparatus is used they will be found a valuable addition.

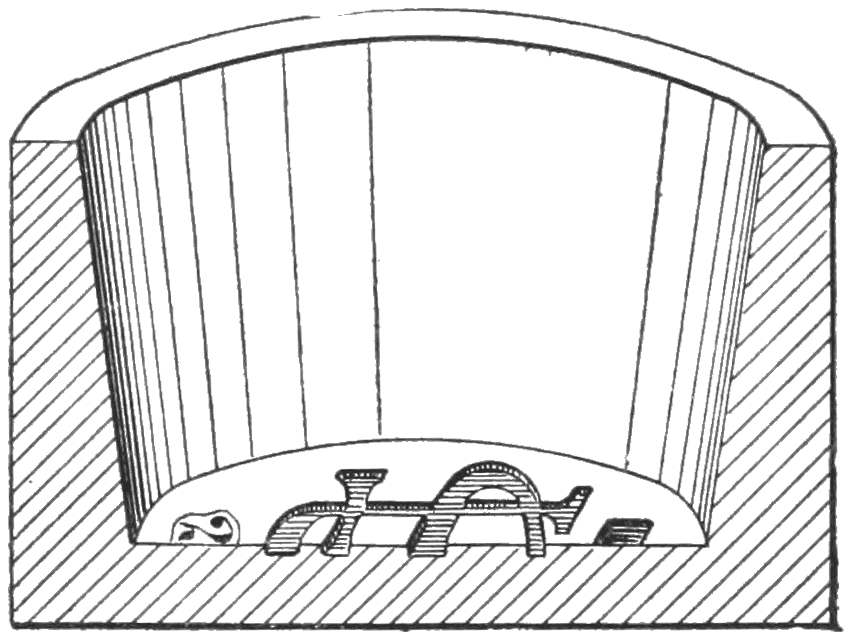

In describing the simple press it was said that it could be made of wood. It is evident that a wooden press could not be used for direct heating. Such a press must be used in a hot chamber or vulcanizer, properly so called. Originally rubber stamps were generally made in chamber vulcanizers.

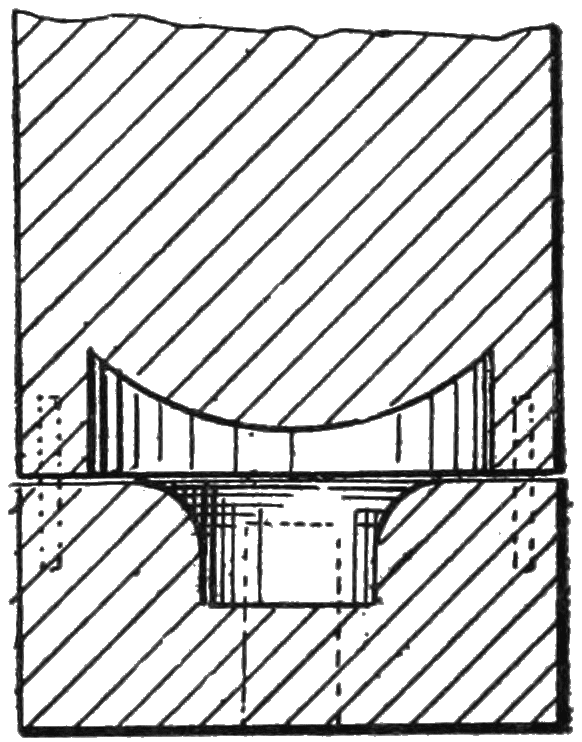

The next cut shows a combined matrix making, moulding and vulcanizing apparatus of very convenient and compact form and adapted for rapid work. As the press stands in the cut the matrix press is seen in front. A box or chase is carried under its platen by two trunnions, so as to be free to oscillate to a limited extent. The type model is secured in this box. Above this box or chase is a cross-bar with screw and platen attached, connected at will to two standards or pillars, so as to constitute the matrix press.

A matrix plate swings on a hinge joint between the two presses. The hinge-pin is removable. Its62 ends can be seen projecting to right and left of the press columns. The hinge is at such a height that when the matrix plate is swung forward over the type box it will rest upon it in a nearly horizontal position. The pivoted box will adjust itself so as to come into parallelism with the plate.

When the matrix plate is swung back it falls upon the base plate of the vulcanizing press seen in the rear.

In use the composition used for the matrix is spread upon the matrix plate, which may for this63 purpose be removed from the apparatus. It is replaced and the hinge-pin is pushed home. This is done with the composition coated side facing the front of the apparatus as it stands in the cut. The plate is then swung forwards, the platen of the matrix press being turned forward out of the way, and is pressed down upon the type or other model that rests in the type box. If desired the press is used to force it home. The cross-bars of both the presses are arranged to swing each one on one of the pillars, so that the platens are turned to one side out of the way of the matrix plate as it is swung back and forth.

The pressure is released and the platens are turned aside. The matrix plate is swung over to the rear upon the bed-plate of the vulcanizing press. Here it lies with the composition-matrix upwards.

A lighted lamp, either alcohol or gas, is placed beneath the bed-plate of the vulcanizing press on which the matrix rests. This quickly dries it and brings it to a good curing temperature. The cross-bar and platen may be swung over it during the heating so as to be heated at the same time. The matrix is talced when dry and hot; the mixed sheet itself talced, is placed upon the matrix, the platen is screwed down upon it, and in a minute or two the moulding and curing is completed.

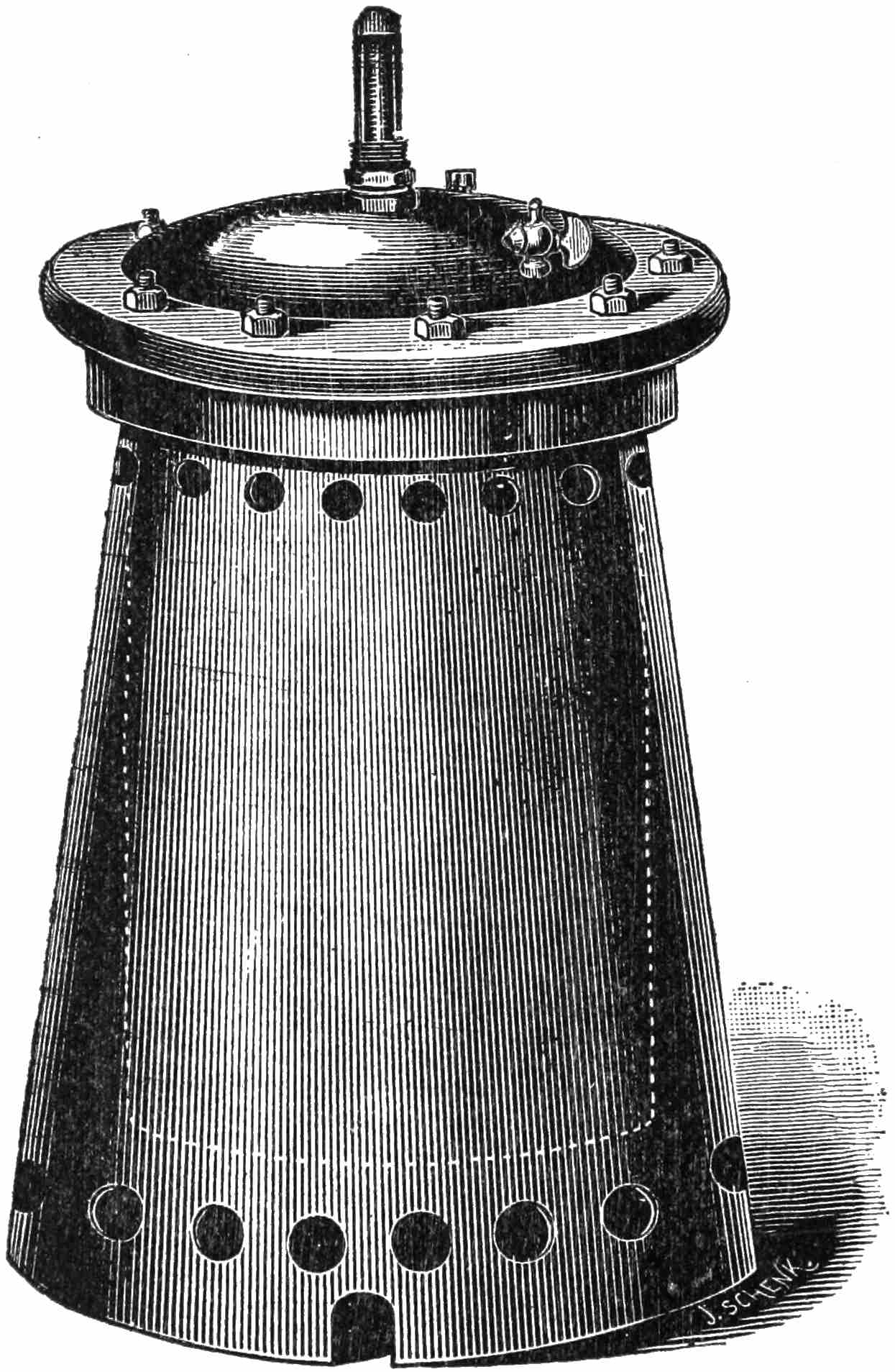

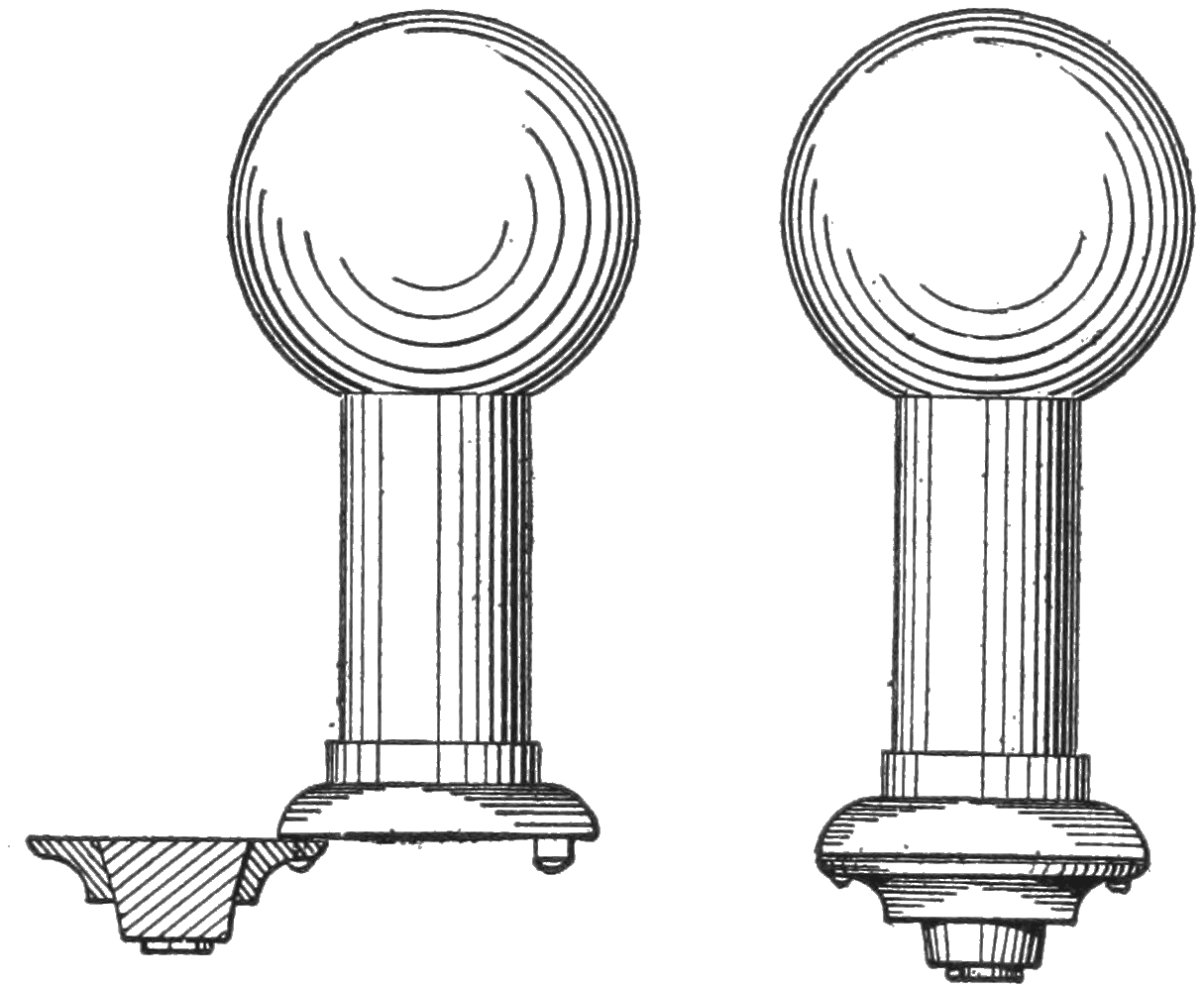

A vulcanizer, properly speaking, is a vessel arranged to heat to a definite degree any desired articles64 which are to be cured. The favorite type have been the steam vulcanizers. If steam is generated from water at a constant pressure, other things65 being equal a constant temperature will be produced. By raising or lowering the pressure the temperature can be made to rise or fall. A steam vulcanizer is a tightly sealed vessel which contains water and which is provided with a thermometer or a pressure gauge as well as a safety-valve, safety disc or safety plug. By keeping the gauge at constant pressure or by keeping the thermometer constant the temperature can be limited and kept steady. The following table gives some pressure in pounds per square inch with temperatures corresponding to steam of such pressures:

| Lbs. per square inch. | Temp. Fahr. | Temp. Cent. |

| 45.512 | 275° | 135° |

| 52.548 | 284° | 140° |

| 60.442 | 293° | 145° |

| 67.408 | 300.2° | 149° |

The illustration, p. 64, shows a vulcanizer of modern type made for rubber stamp work. In some recent vulcanizers the water and steam are excluded from the vulcanizing chamber, being contained within double walls forming a steam jacket and maintaining a constant heat within the chamber. These illustrate a point that has been much misapprehended, namely that curing is independent of pressure or atmosphere. Because vulcanizers have generally been filled with steam at high pressure many have supposed that the steam or pressure had something to do with their action. The fact is that66 it is only the heat due to the steam at such pressure that is instrumental. Steam is a very powerful radiator and absorber of so called radiant heat. For this reason an atmosphere of steam maintains all parts of the vulcanizer at an even temperature and is to that extent advantageous. Its presence and the pressure it generates are not by any means required for vulcanizing. Its pressure is entirely without effect.

To use a steam vulcanizer, water is introduced,67 the article in the press or mould is placed in it, and the top is secured. Heat is then applied, best if on the small scale, from a Bunsen gas burner gas, or oil stove. Either the pressure gauge or thermometer may be watched, and the flame turned up or down to keep it at the proper temperature.

Moulding cannot be executed in the ordinary closed chambers. The press must first be heated to the temperature of boiling water or thereabouts and the moulding is then effected by screwing down the mould screw, upon the sheet and matrix. It is then placed in the vulcanizer and cured.

The manufacturers supply gas regulators which automatically regulate the gas supply. These are worked by the steam pressure. If any one wishes to study the practical manipulation of small steam vulcanizers he can see them in use at any dentist’s office.

There is no need of a steam vulcanizer for ordinary stamp work. The hot press system already described answers every purpose and is in use by the most advanced manufacturers for thin sheet work. But if a wooden moulding press is used then it must be heated in a vulcanizer or some kind of oven or hot chamber.

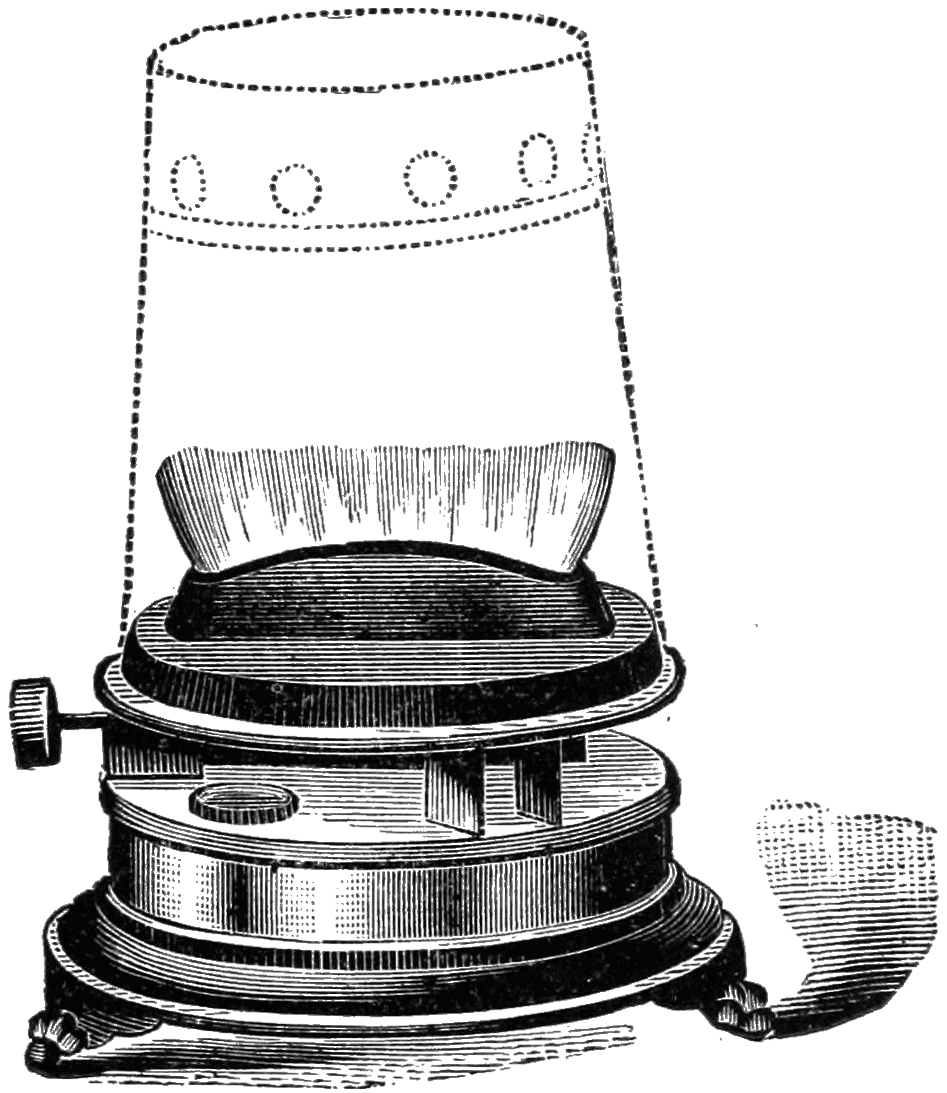

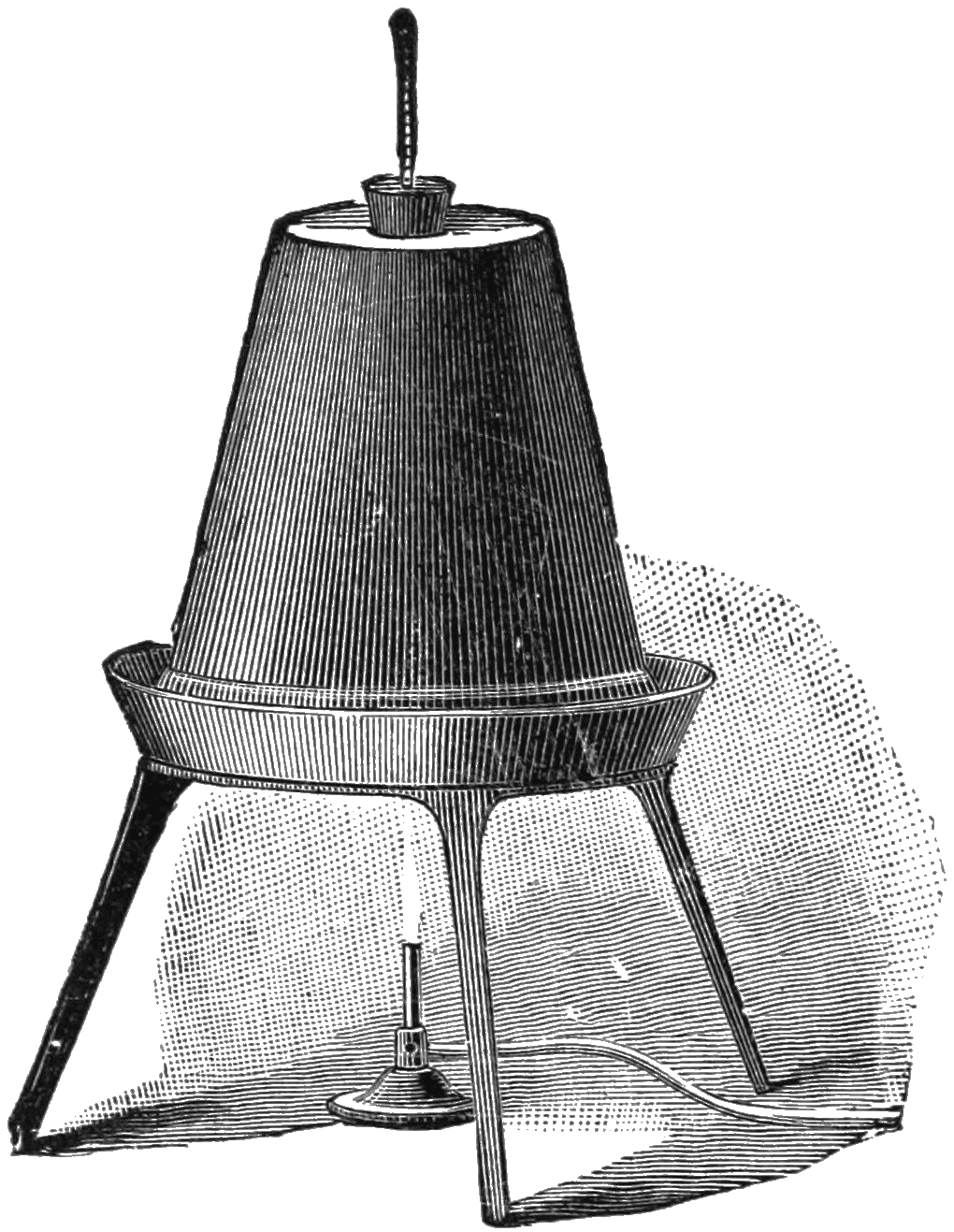

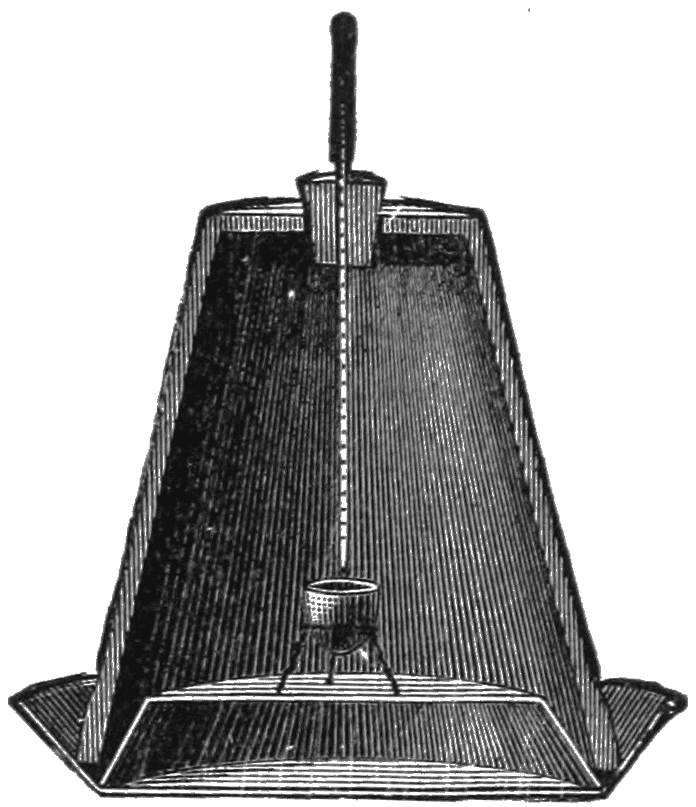

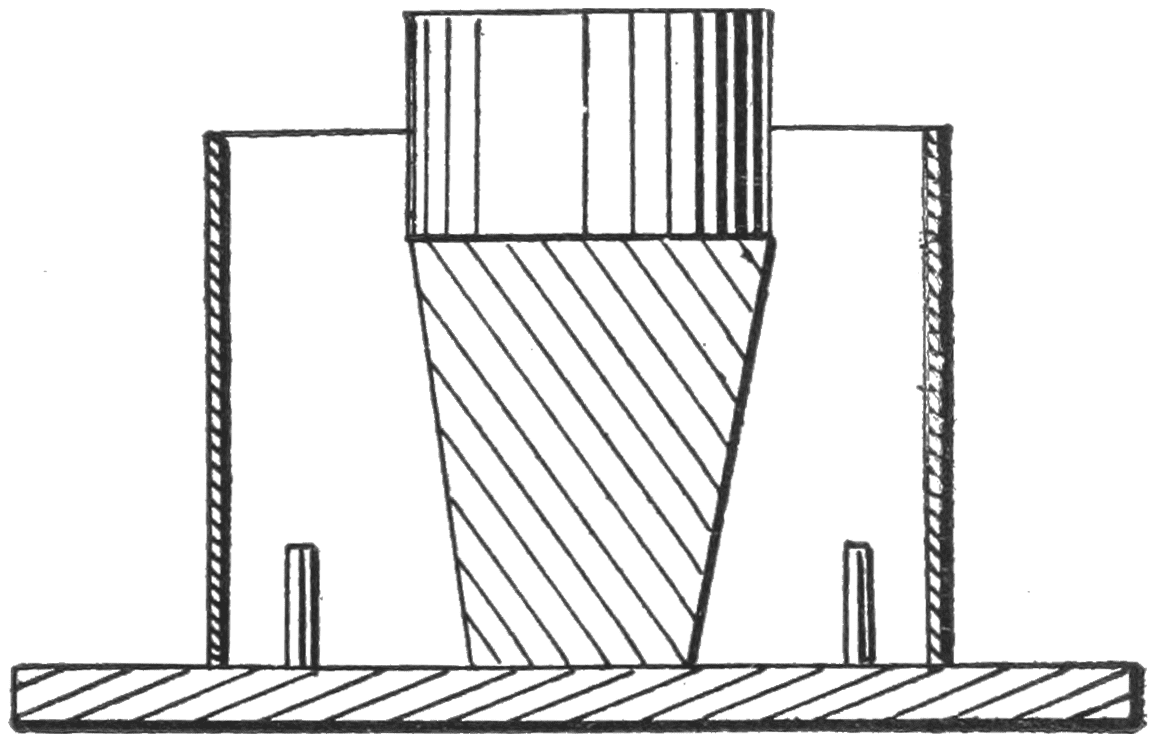

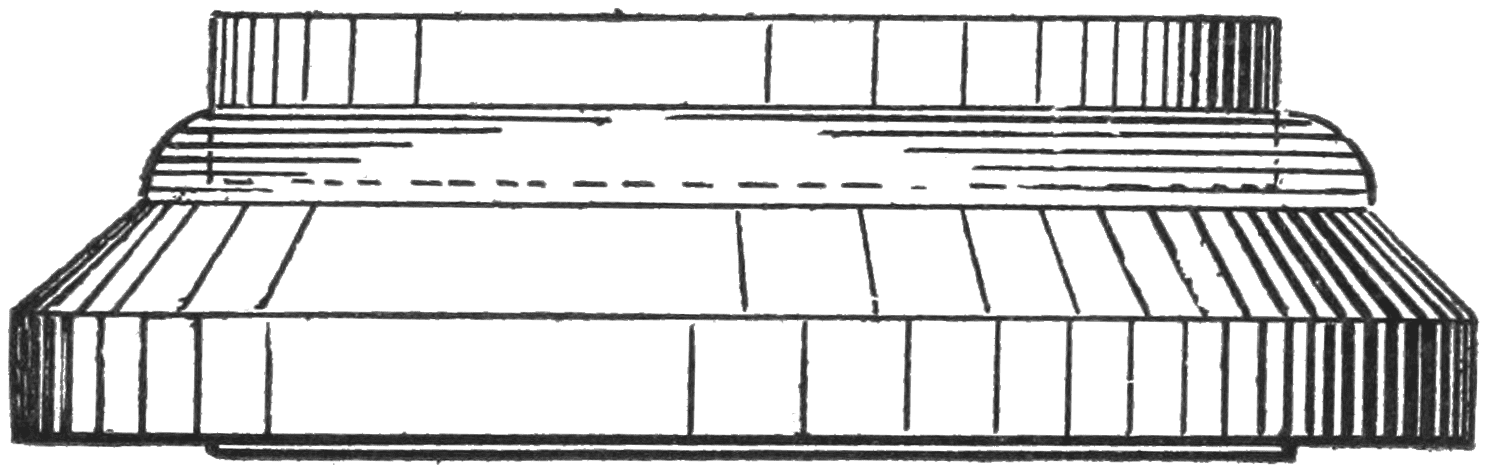

A very simple and reasonably satisfactory oven or air bath can be made from a flower pot and a couple of tin plates. A plate larger in diameter than the mouth of the flower pot forms the base of the apparatus. This is supported on a stand over the gas68 lamp or other source of heat. A smokeless flame or one depositing no lampblack should be used. Alcohol or a kerosene oil stove illustrated on page 59 are excellent. On this plate a smaller plate is inverted, which latter must be so small as to be surrounded by the flower pot and to be included within it when the pot is placed over it like an extinguisher.

A chemical or round stemmed thermometer is arranged to go through the aperture in the upturned bottom of the pot. This may be hung from a support or it may be secured by passing through a hole in a cork or block of wood. Its bulb should69 be near the part of the chamber to be occupied by the mould or press.

The press with the article to be cured is placed upon the inner plate. The temperature is maintained at the proper point by regulating the heat, and all the conditions for excellent work are supplied. The disposition of the apparatus is shown in the cuts.

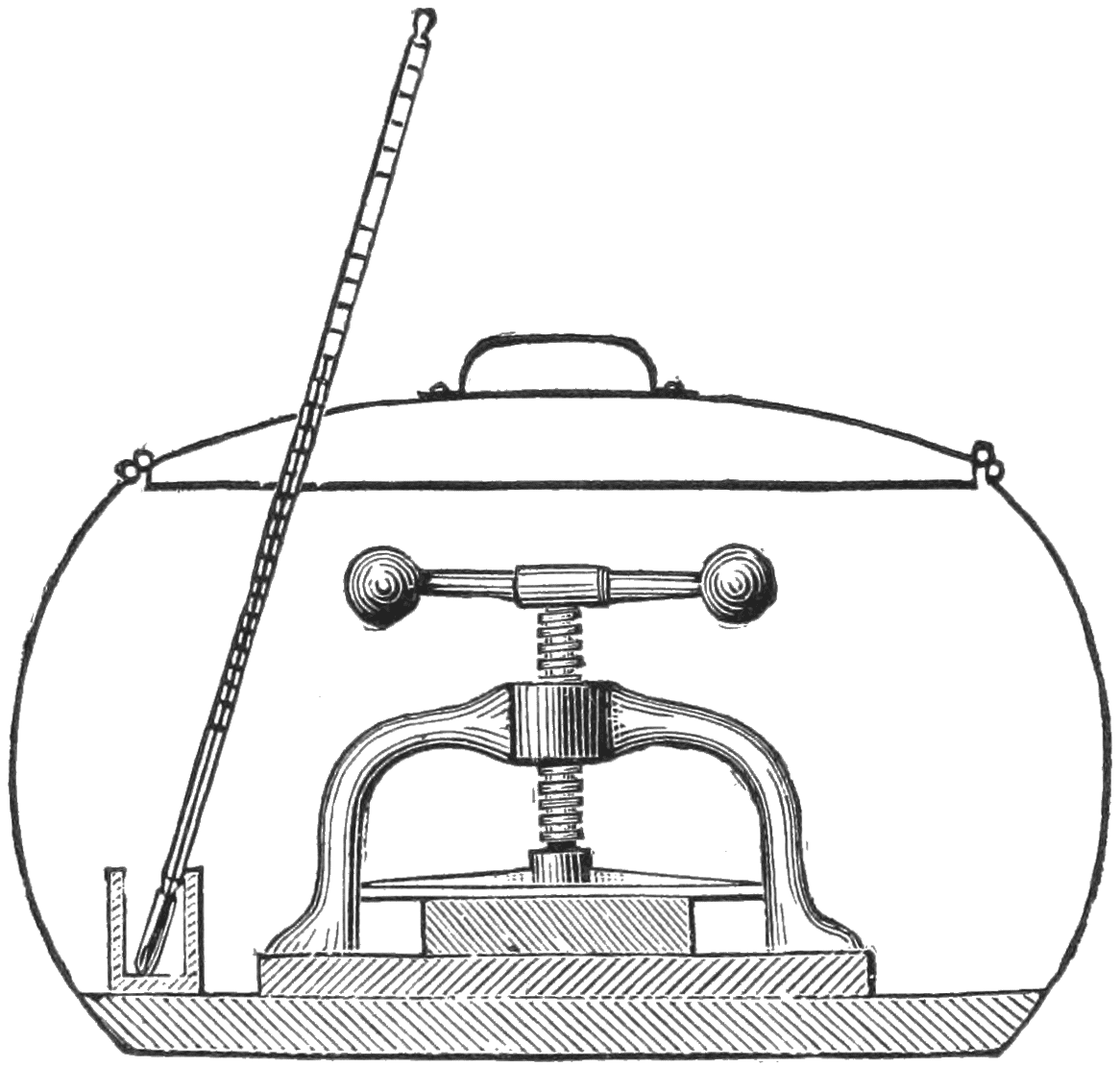

Another arrangement equally simple is given in the next cut. An iron kettle has a layer of type metal or lead poured an inch thick cast within it upon its bottom. A thermometer passing through a hole in the cover enters a cup of glycerine that stands upon the bottom. This gives the temperature.

The object of having a thick or a double bottom is to prevent excessive radiation of heat from any one part. The essential condition for good operation70 is to maintain an even temperature throughout the chamber.

The thermometer is not an absolute necessity. By removing the press from time to time and inspecting the overflow of india rubber the progress of the operation can be watched. An extra piece of india rubber may be placed on a piece of wood by the side of or upon the wooden portion of the press, and its condition can be taken as the criterion. Pressure with the point of a knife will tell the vulcanizing point.

By the press system of curing, a heat far above the vulcanizing temperature may be made to do good work by a very short application. There is71 however danger of burning the work if left in too long. If the air-bath with thermometer or the steam vulcanizer is used, and the heat is kept down to the proper curing temperature, there is no danger of burning the india rubber even if the curing is considerably prolonged.

As the flower pot has often to be lifted off for introduction or removal of the press, and as it gets quite hot, a holder of some kind is requisite. A piece of heavy blotting paper is very convenient for this purpose.

The flower pot system with thermometer can be further simplified by being used on a stove or range. A china saucer inverted, or some similar support, should be placed under the pot. A part of the stove at very low heat will suffice. The kettle vulcanizer, can also be placed on a stove so as to dispense with gas or oil.

Finally, as the last step in simplifying the work, a stamp can be made without any special apparatus beyond a hot flat iron. The matrix may be placed on a stove where the heat is rather low, the talc-coated mixed rubber sheet placed upon it, and on this a hot flat iron. In a few minutes if the heat is sufficient the stamp will be finished.

A few words may be said about the type. High spaces and quads between the letters should be used, such as will come up to the shoulder of the type, as has been said. But a very nice effect is produced by using low quads between words. This leaves72 each word elevated by itself, producing a good appearance.