Notes on the Development,

Use and Care of Modern Field Artillery

Equipment, Including the

3” Field Gun, American, French and

British 75s, the 4.7” Gun, 155-mm

Howitzer, GPF, Fire Control Instruments,

Signal Equipment and small

arms used by the Field Artillery—automatic

pistol, automatic rifle and

the Browning machine gun.

Compiled by

JAMES P. KELLY

1ST LIEUT. FIELD ARTILLERY

U. S. ARMY

COPYRIGHT

BY

THE UNIVERSITY CO-OPERATIVE STORE

UNIVERSITY OF MISSOURI

COLUMBIA, MO.

1920

[Pg 2]

To those efficient officers and inspiring gentlemen who interested the “youngsters” of the Yale batteries in the service of their country, and, in a time of peace, prepared them for the duties which they later performed in a time of war, this book is gratefully and respectfully dedicated.

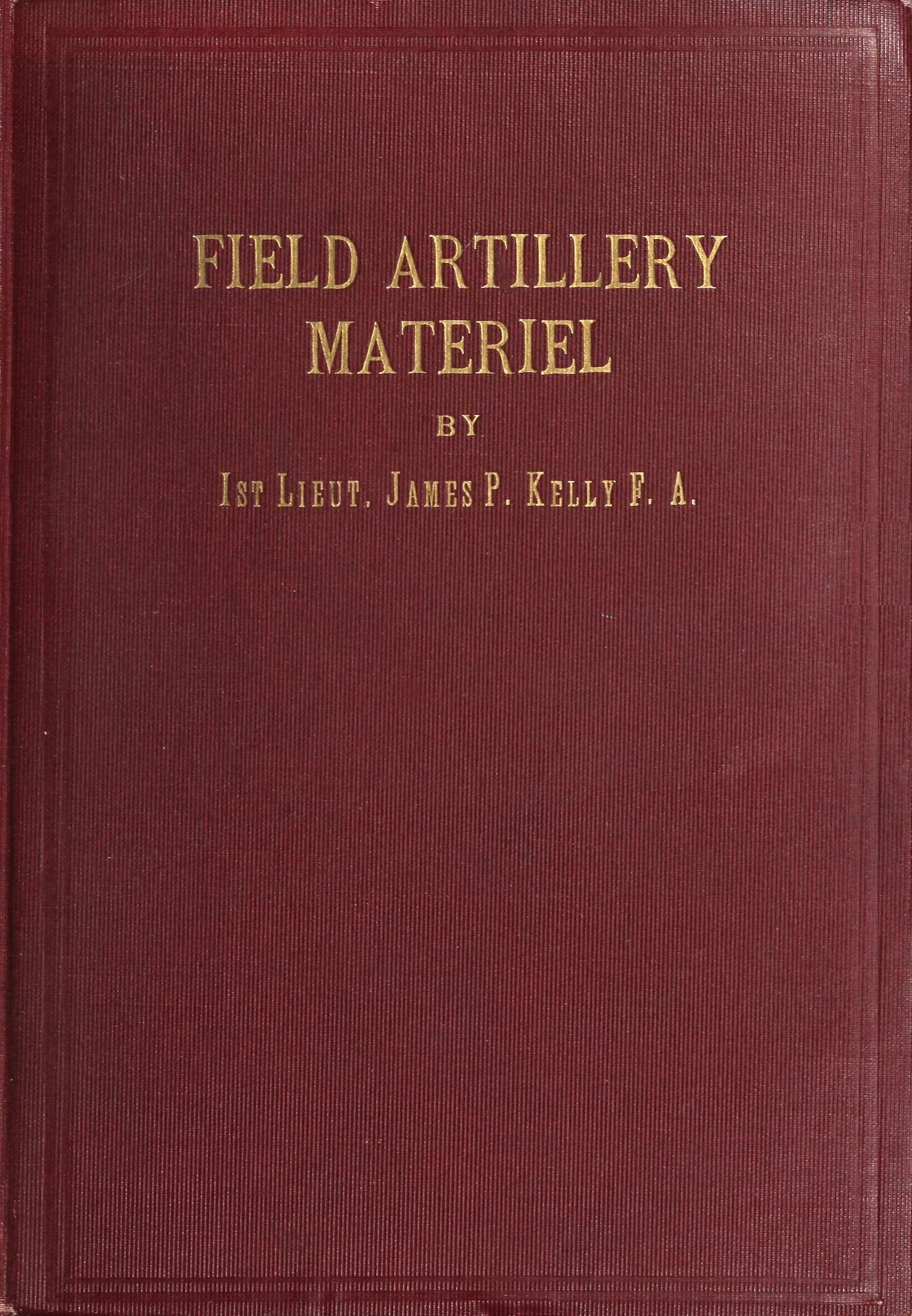

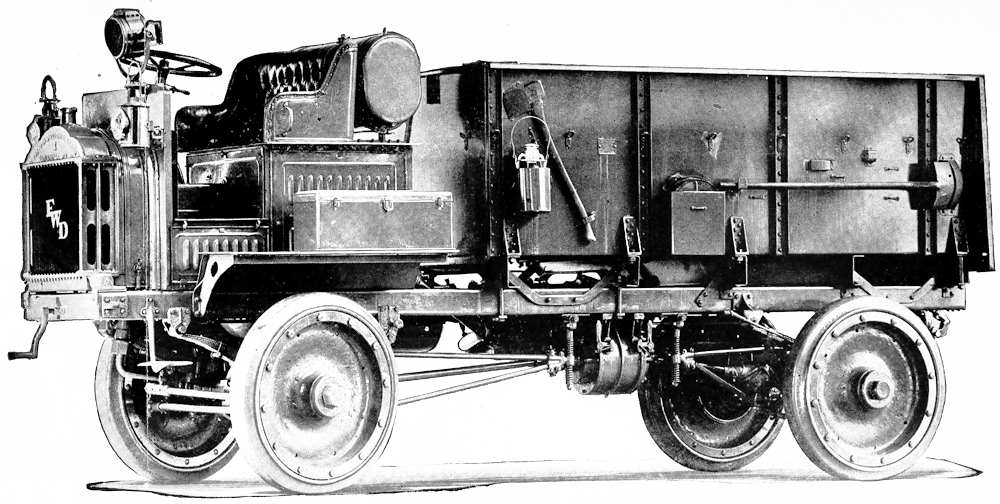

ARTILLERY OF THE FUTURE.

SELF-PROPELLING CATERPILLAR MARK VII 75-MM. GUN. MODEL 1916.

SELF-PROPELLING CATERPILLAR MARK II 155-MM. FILLOUX GUN.

[Pg 3]

The compiler of this volume believes that the Field Artillery student should possess a broad, general knowledge of the history and development of ordnance, with some idea of the elements of gun construction; that he should be acquainted with the organization, ideals and practicalities of modern field artillery armament; that he should know the ammunition and the guns in our Field Artillery service with their care and maintenance.

It is also believed that in the R. O. T. C. units of Field Artillery the student should make the complete 3” equipment the basis of his knowledge of materiel. He should become thoroughly and familiarly acquainted with this weapon, and, to a lesser extent, with the other light pieces which are in present use. The reason for this being that our experience in the World War has shown that a thorough knowledge of one class of materiel permits a ready adaptation to any other type. He should also know the manner of functioning of the 4.7” and 155-mm rifles, with a somewhat more intensive knowledge of the 155-mm howitzer—and with a sound knowledge of the capabilities and limitations of all.

To complete his instruction in materiel he should know the use and care of Fire Control equipment, Signal equipment, and the small arms used in the field artillery, pistol, automatic rifle and machine gun.

The lack of a single volume covering the above has been the cause of the compilation of this book. The compiler hopes the R. O. T. C. student will find in it a text which will[Pg 4] be interesting, instructive and comprehensive. To the lieutenants in charge of Department “A” and to those who aspire to that responsibility it is hoped that this work will prove a valued addition to their professional libraries.

The subjects covered herein have been taken wholly or in part from the various official handbooks, from “Ordnance and Gunnery, U. S. M. A.,” “Naval Gunnery, U. S. N. A.,” “America’s Munitions,” “Gun Making in the U. S. A.,” “Ordnance and Gunnery for Field Artillery Officers,” “Artillery Firing,” “The Field Artillery Journal,” Ordnance Doc. 2033, from lecture notes taken at the School of Fire, Brigade Training Pamphlets, and various other sources.

The compiler is indebted to Lt. Col. Lloyd E. Jones, F. A. and Major H. C. Jackson, F. A. for the valuable advice and the helpful assistance they rendered in this compilation.

[Pg 5]

| Chapters | Page | |

| I. | Definitions. | 11 |

| II. | History and Development of Materiel. | 16 |

| Biblical references—Use by Romans in Punic wars—Greeks; Chinese use of pyrotechmy; French field artillery in the time of Charles VIII; Gustavus Adolphus and artillery in the 17th century; Louis XIV; Gribeauval’s work in 1765; Shrapnel, 1808; Smooth bores to rifles, middle of 19th century; French “75;” Period 1897 to date. | ||

| III. | Elements of Gun Design and Construction. | 27 |

| Guns—wire wrapped and built-up; twist; breechblocks; carriages; traversing mechanisms; elevating mechanisms; recoil systems. Air and spring recuperators; shields; sights; wheels; trails. | ||

| IV. | Modern Armament. | 46 |

| Discussions of types of artillery and their organization; missions and guns suitable to accomplish different missions; ideal and practical types for divisional corps and army artillery. | ||

| V. | Three-inch Field Gun. | 62 |

| Weights and dimensions. | ||

| Description of gun, carriage, caisson and limbers; functioning of principal parts. | ||

| Mounting and dismounting.[Pg 6] | ||

| VI. | 75-mm Model 1897 (“French 75”). | 84 |

| Weights and dimensions. | ||

| Description and functioning of principal parts. | ||

| Care, preservation, dismounting. | ||

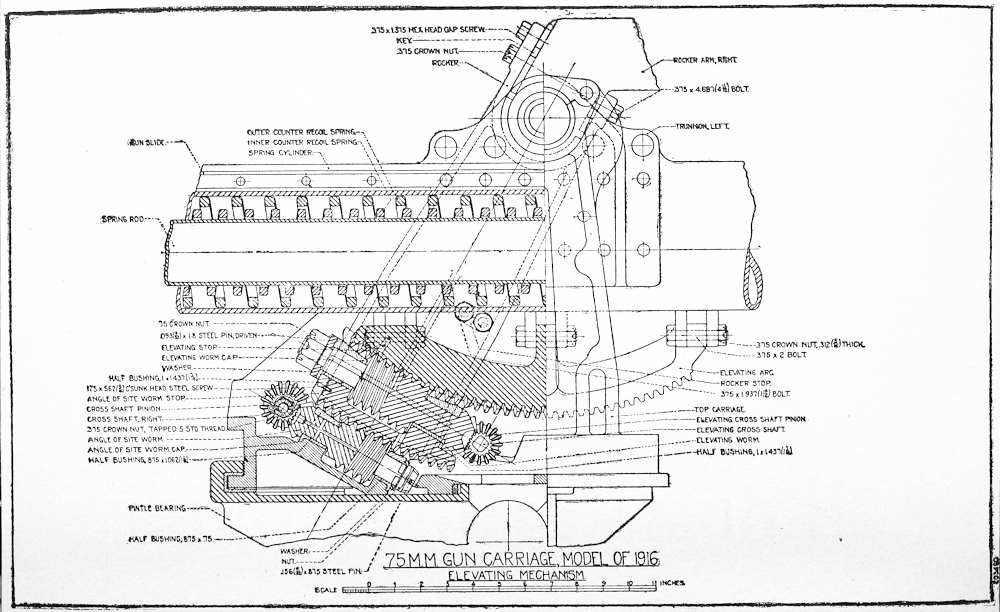

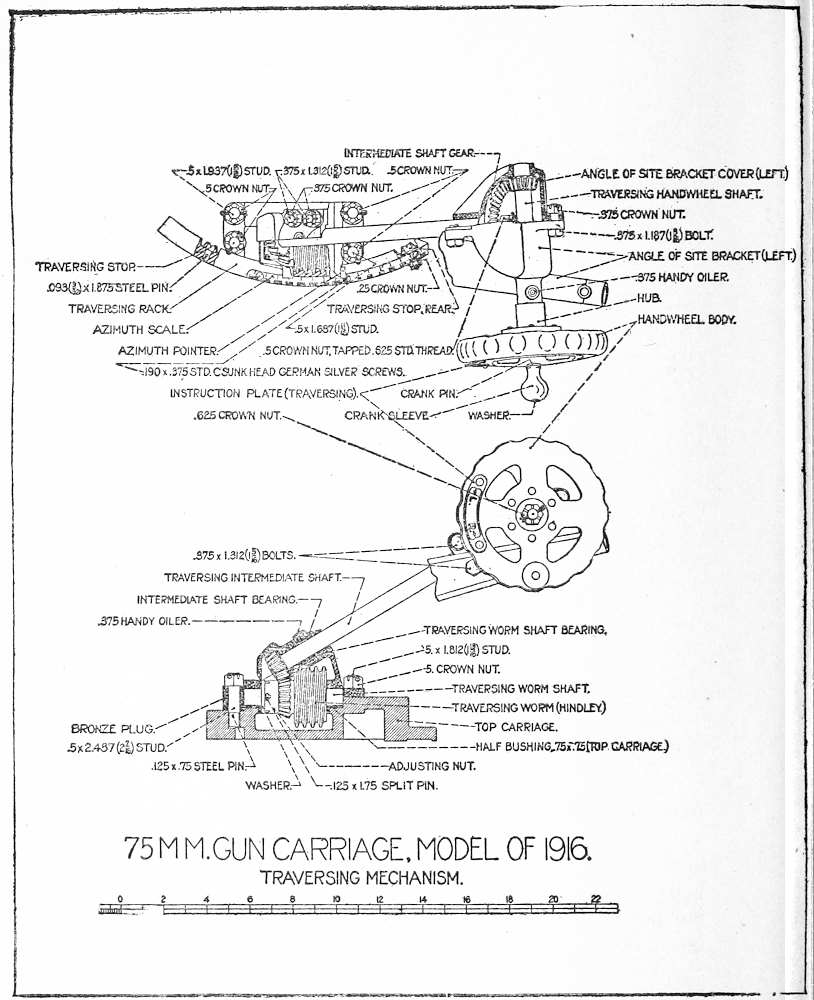

| VII. | 75-mm Model 1916 (“American 75”). | 105 |

| Weights and dimensions. | ||

| Description and functioning of principal parts. | ||

| Care, preservation, dismounting, mounting. | ||

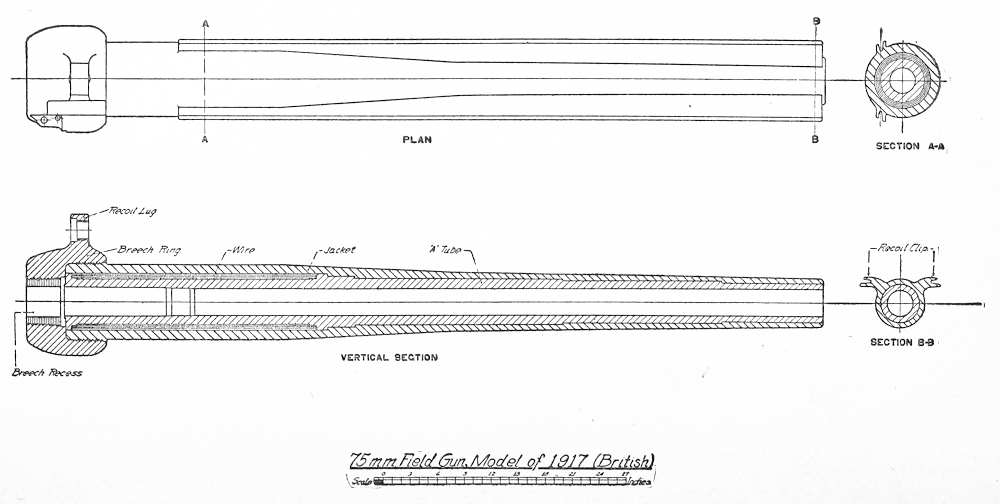

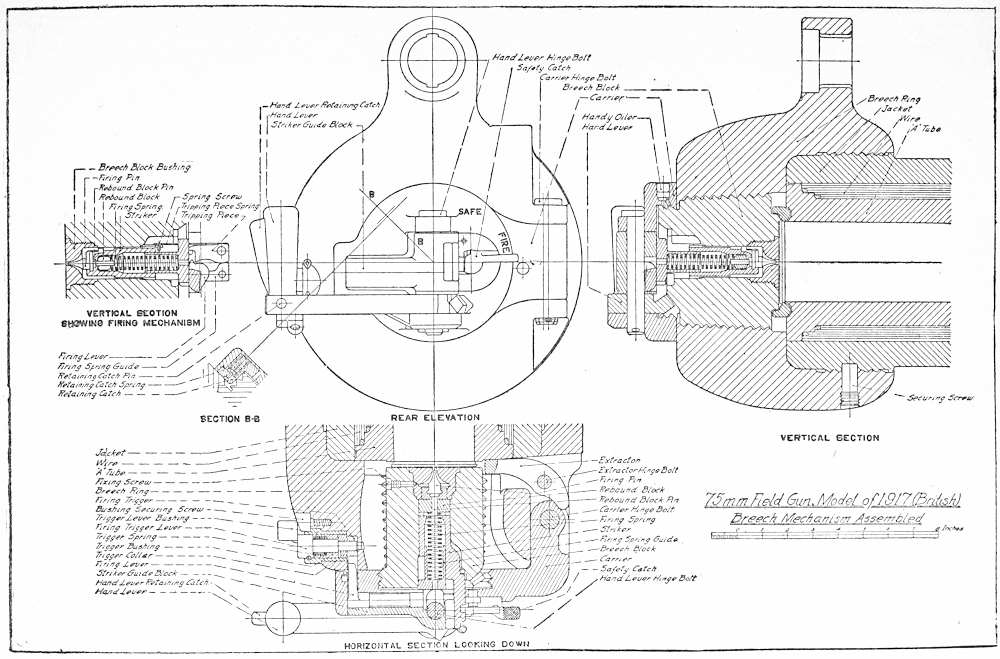

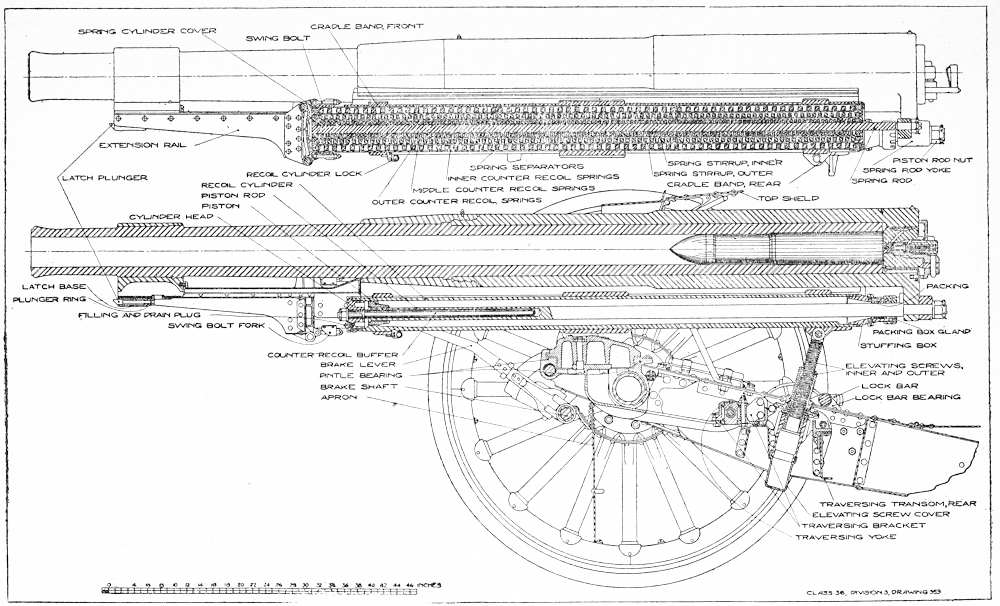

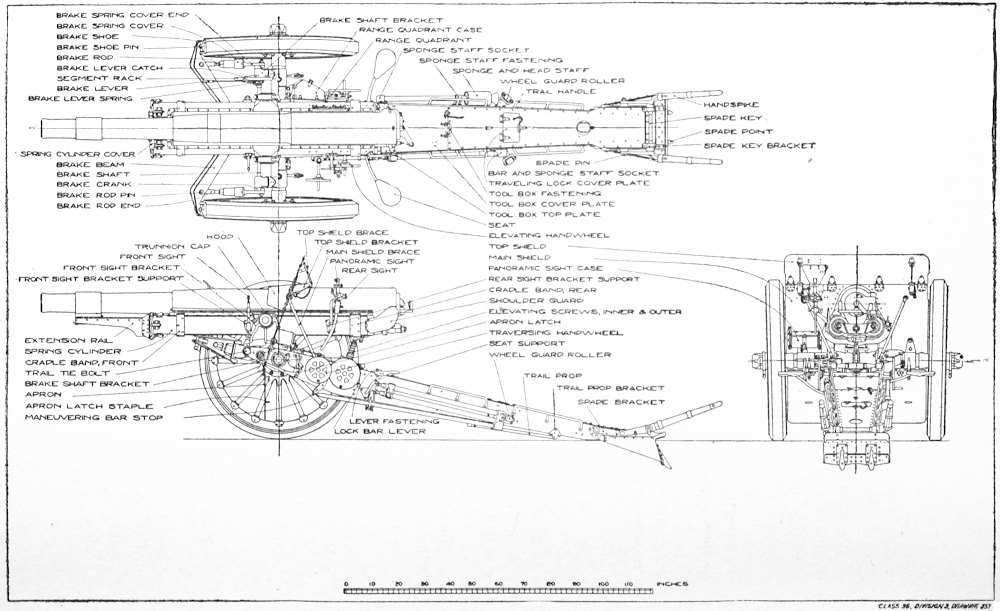

| VIII. | 75-mm Model 1917 (“British 75”). | 147 |

| Weights and dimensions. | ||

| Description and functioning of principal parts. | ||

| IX. | 4.7” Rifle Model 1906. | 154 |

| Weights and dimensions. | ||

| Description and functioning of principal parts. | ||

| X. | 155-mm Rifle (Filloux Gun) (GPF). | 160 |

| Weights and dimensions. | ||

| Description and functioning of principal parts. | ||

| XI. | 155-mm Howitzer Model 1918. | 167 |

| Weights and dimensions. | ||

| Description and functioning of principal parts. | ||

| Notes on dismounting and mounting—cleaning.[Pg 7] | ||

| XII. | Explosives, Ammunition and Fuzes. | 199 |

| Explosives—classes, fillers, H. E., nitrogen compounds. | ||

| Ammunition—classes, discussion of fixed, semi-fixed and separate ammunition, primers, charges, construction of different types of shell, care. | ||

| Fuzes—principle of operation, arming, classification, precautions, tables of fuzes giving description, use, etc. | ||

| Ammunition marking. | ||

| XIII. | Care and Preservation of Materiel. | 236 |

| Oils and cleaning materials; tools and accessories; care and cleaning of different parts of carriages, emptying, cleaning and filling cylinders, cleaning bore, breech, springs, etc.; general instructions for care of cloth, leather and metal equipment. Cleaning schedules. | ||

| XIV. | Fire Control Equipment. | 258 |

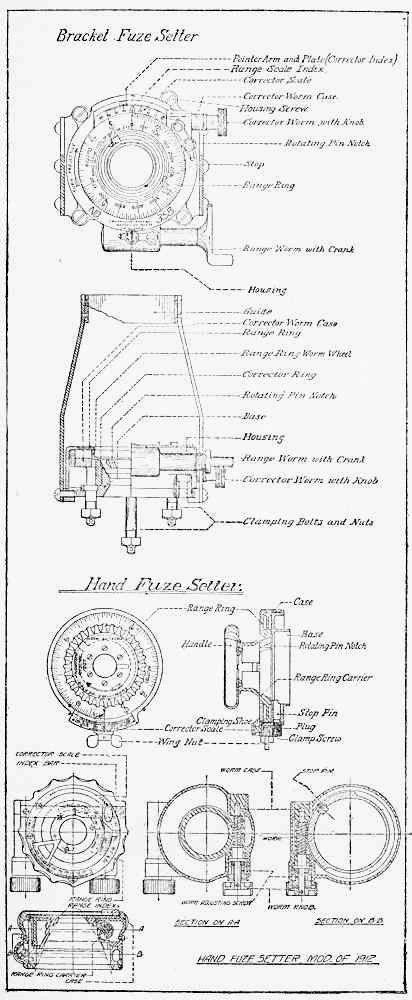

| Sights—line, front and rear, panoramic; model 1915 and 1917 with their use, care and verification. Range Quadrant, care, use and adjustment. B. C. Telescope, model 1915 and Aiming Circle model 1916, with their use, care and adjustment. Range Finder, 1 meter base, use, care and adjustment. Field Glasses. Fuse Setters.[Pg 8] | ||

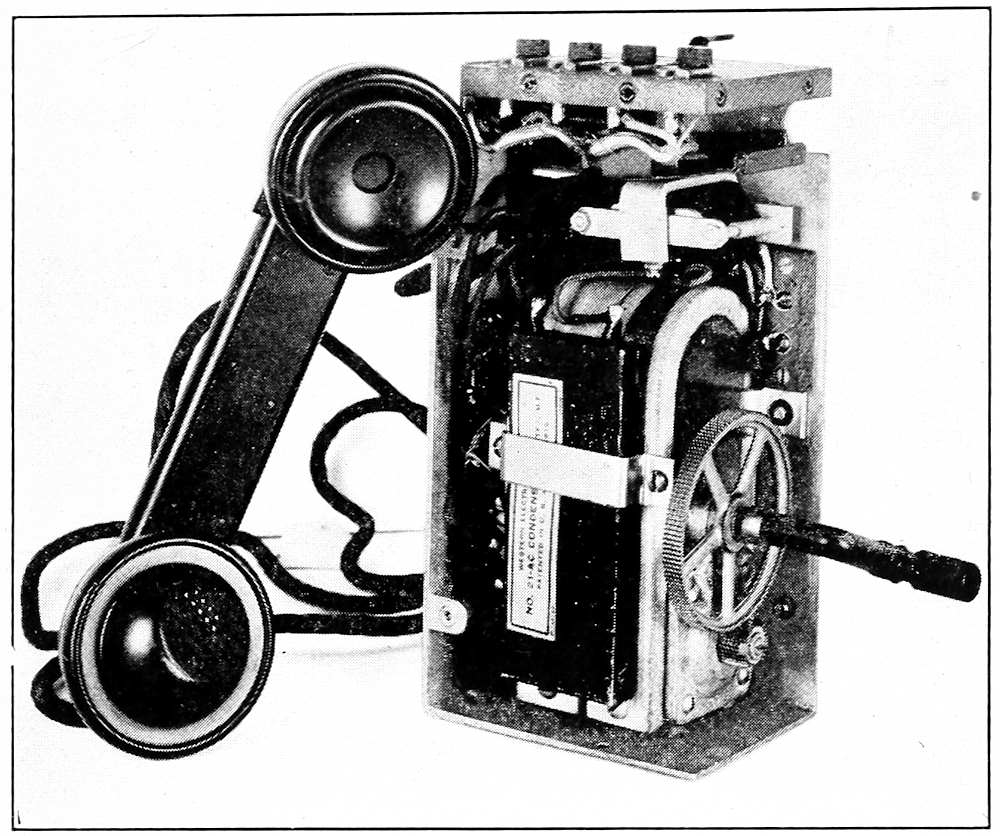

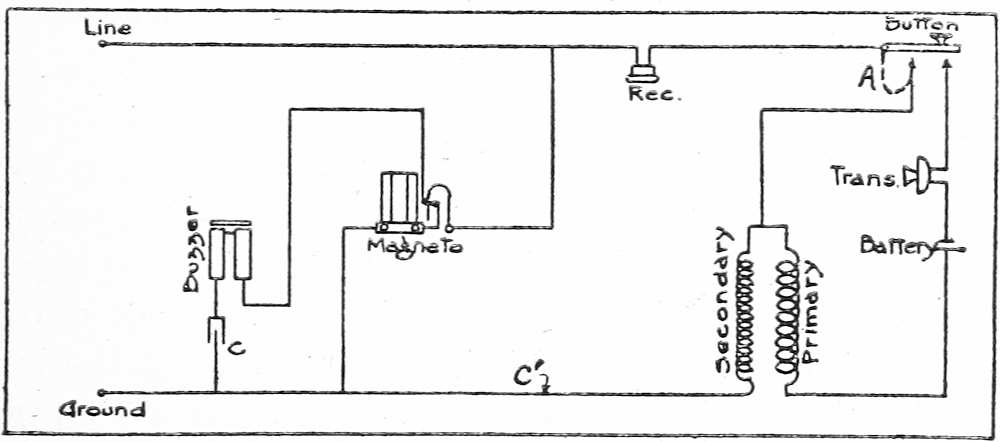

| XV. | Signal Equipment. | 285 |

| Telephones and Monocord Switchboards—description, use, adjustments, trouble shooting and care. | ||

| Projectors—description, use, adjustment, service code for lamps and buzzer, conventional signals. | ||

| Pyrotechnical signaling, classification of rockets, use, code. | ||

| Panels—liaison with airplanes, signals, description of panels, panel code. | ||

| Flags—classification, use of semaphore and wig-wag. | ||

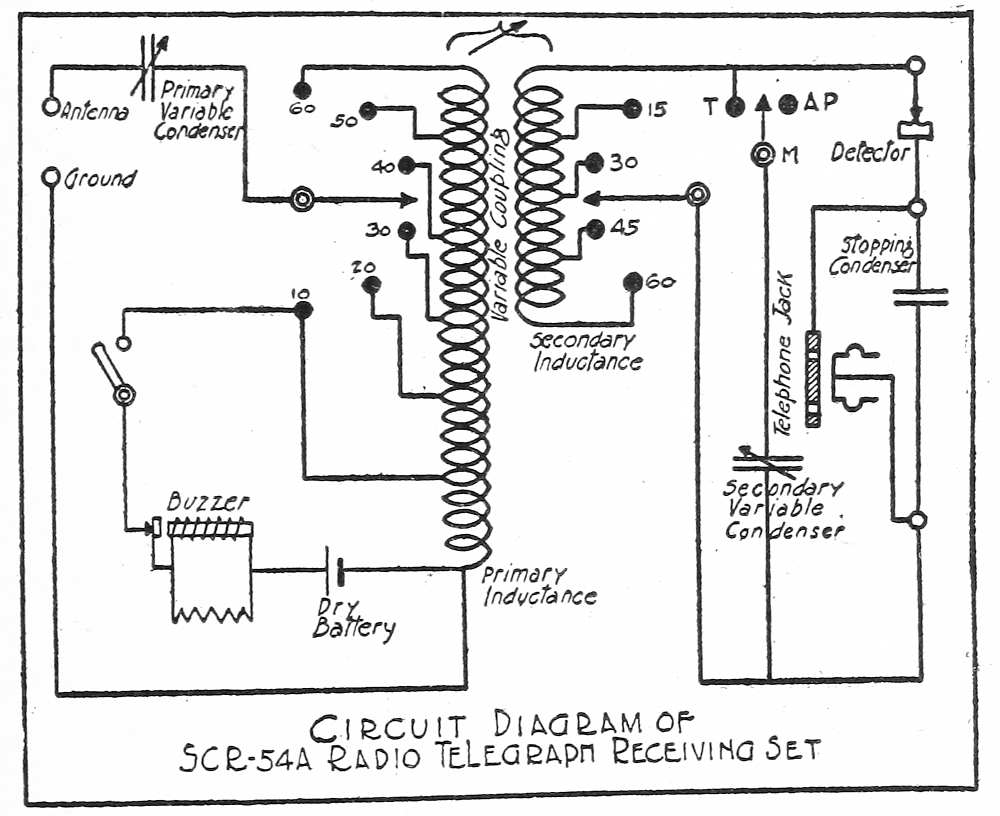

| Radio—Description of equipment, SCR-54 and SCR-54-A Sets, methods of operation, use of vacuum detectors, precautions, sources of trouble, maintenance, reception of airplane signals. | ||

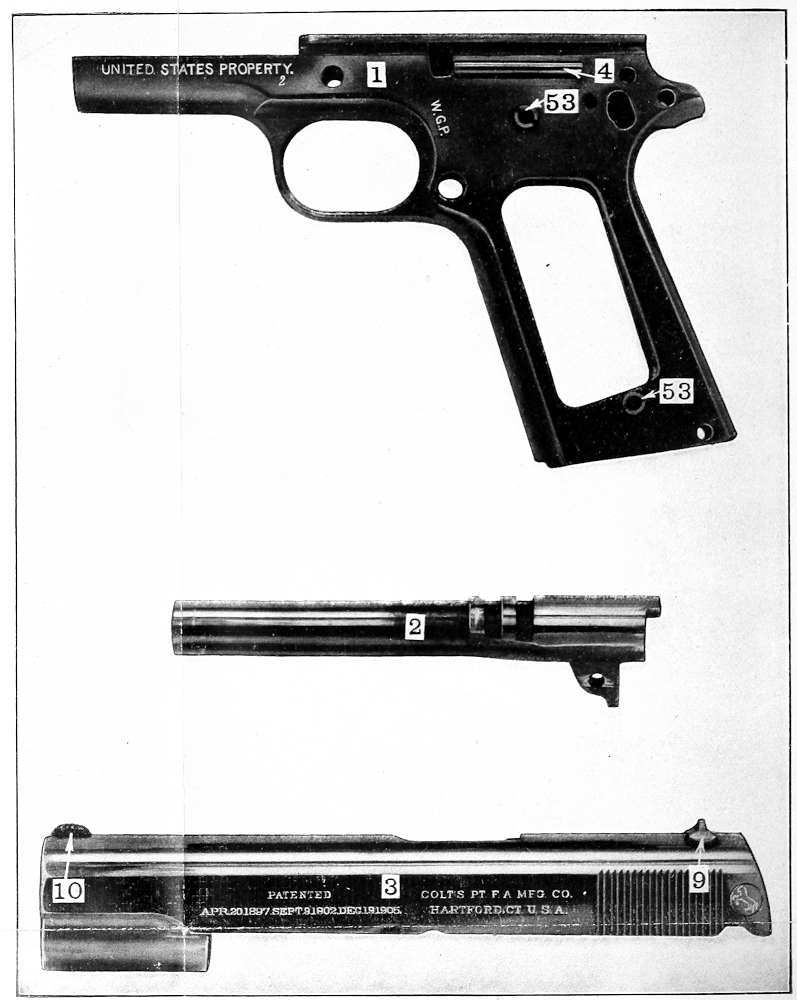

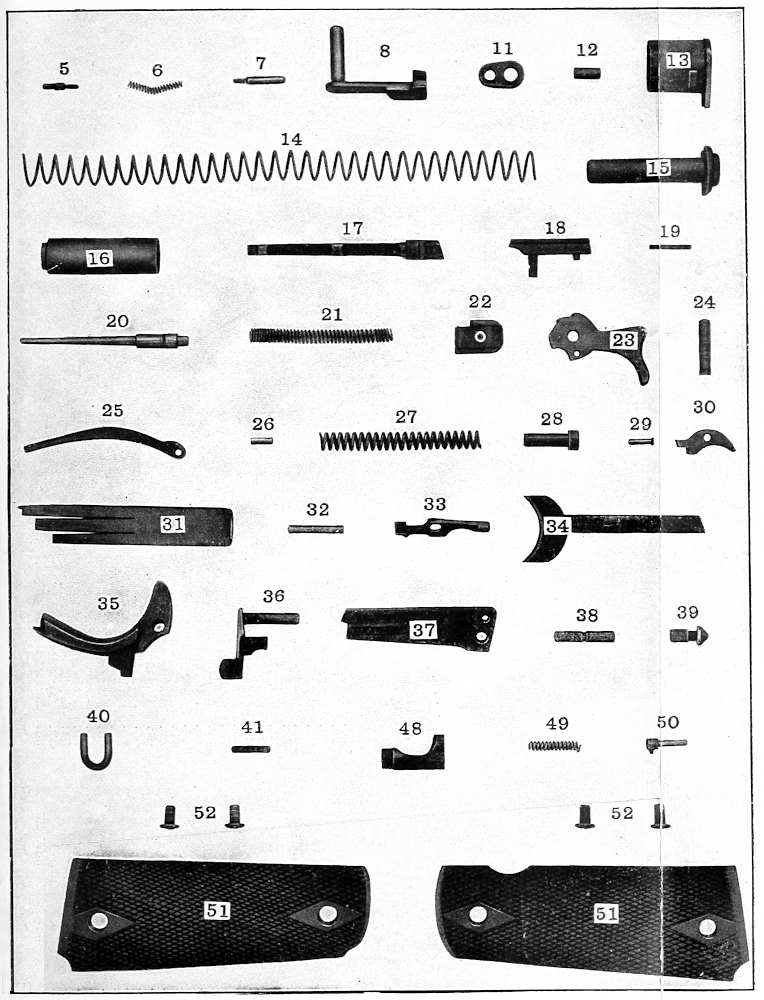

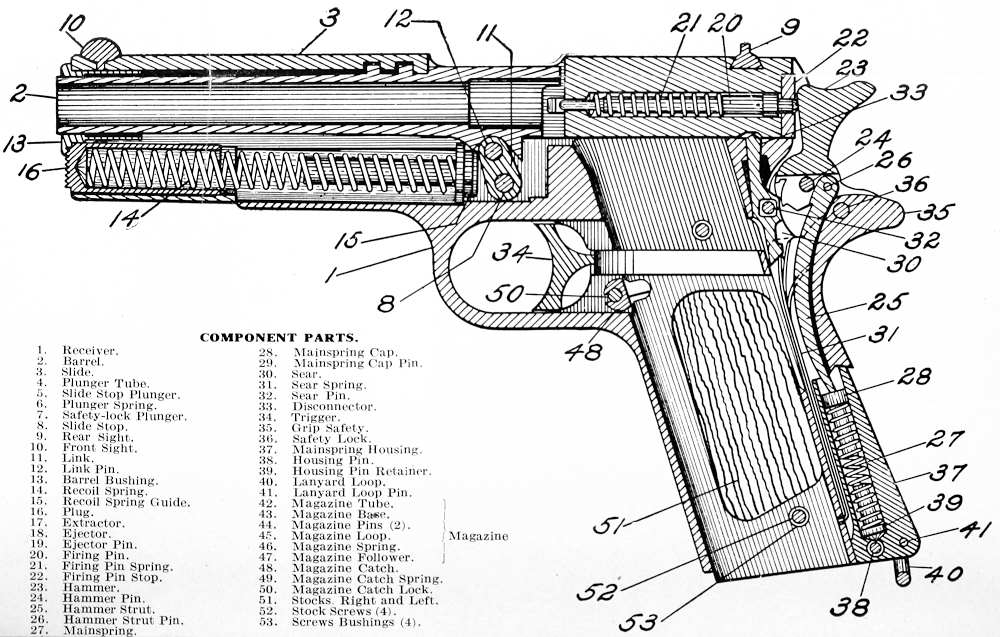

| XVI. | Small Arms. | 315 |

| Pistol, machine gun and automatic rifle—description, use and care. | ||

| XVII. | Motors | 328 |

| Reconnaissance car, Dodge, Harley-Davidson motorcycles. 5-ton tractors, ammunition trucks, cargo trucks. How to drive, sources of trouble, maintenance. | ||

| Appendices. | 349 | |

| A.Gunner’s Examinations—preparations, Cannoneers’ “Don’ts,” training gun crews. | ||

| B. Tabular comparison of light guns used in World War. | 370 | |

| C. Table of Equivalents. | 371 | |

| Index. | ||

[Pg 9]

| Title | Page | |

| Artillery of the Future | Frontispiece | |

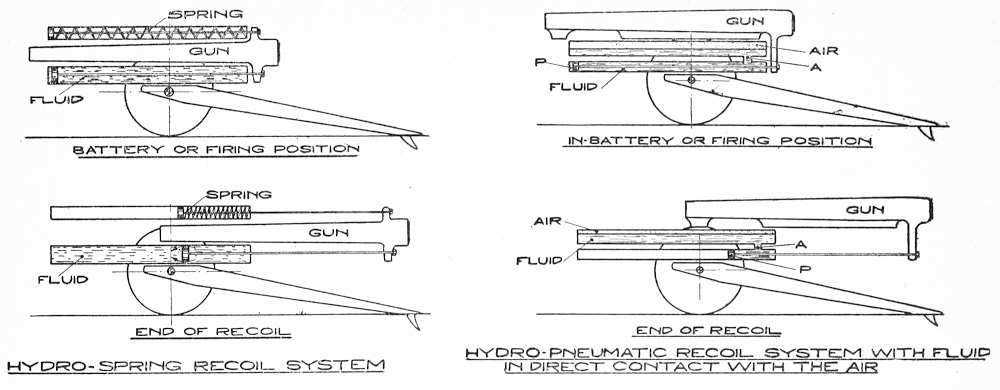

| Diagram Hydro-Springs and Hydro-Pneumatic Recoil Systems | 41 | |

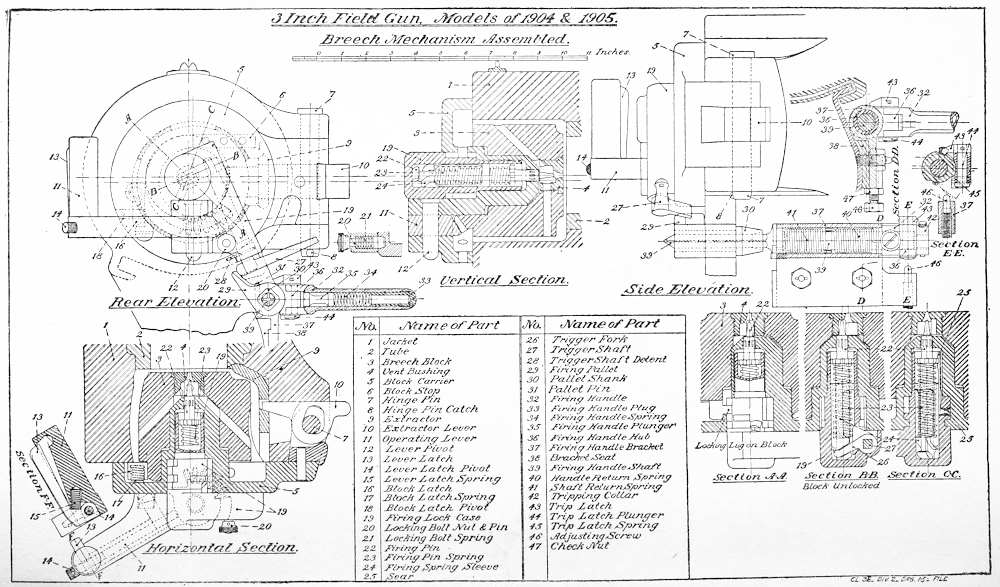

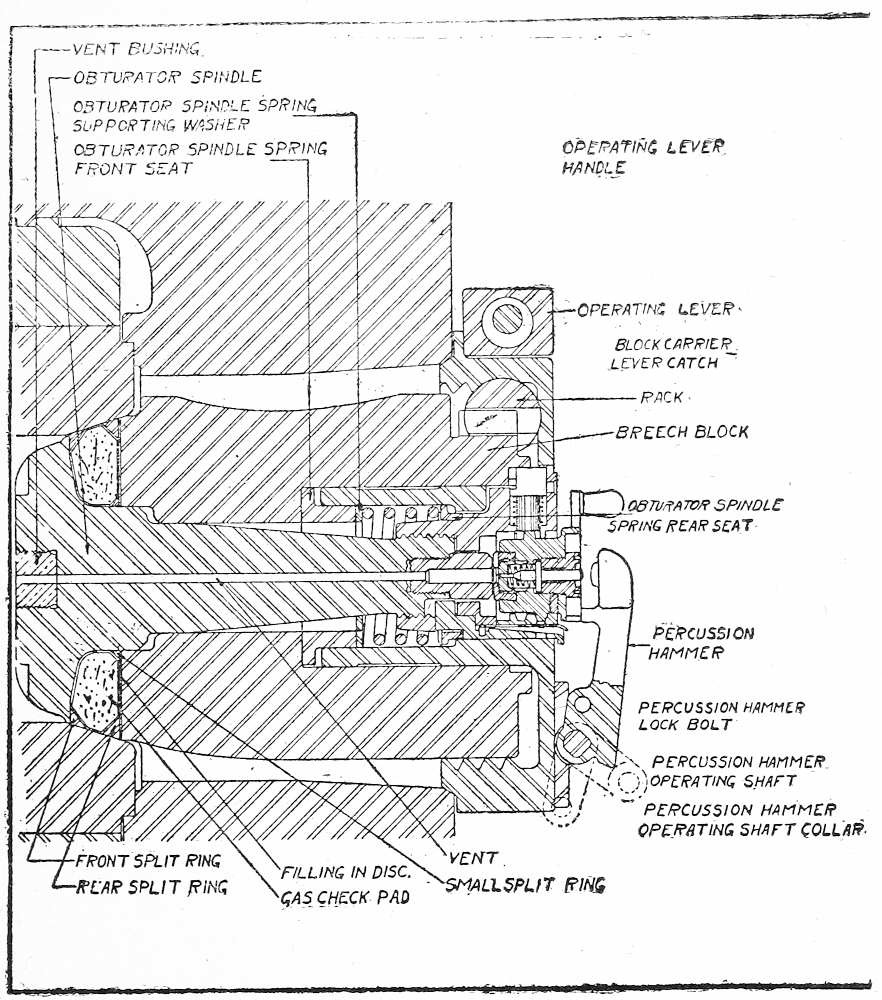

| 3-inch Field Gun Breech Mechanism | Facing 63 | |

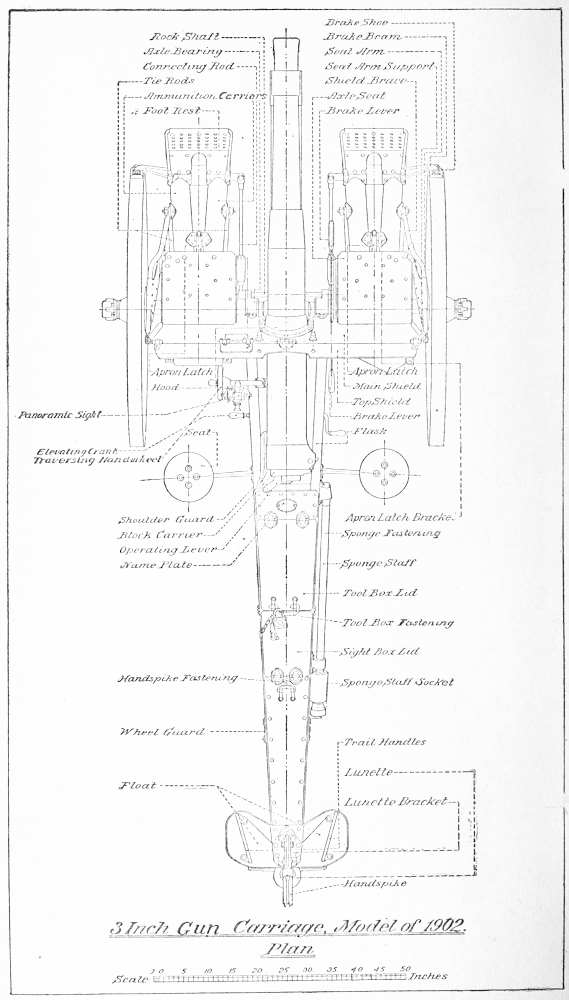

| Carriage Model 1902, Plan View | Facing 65 | |

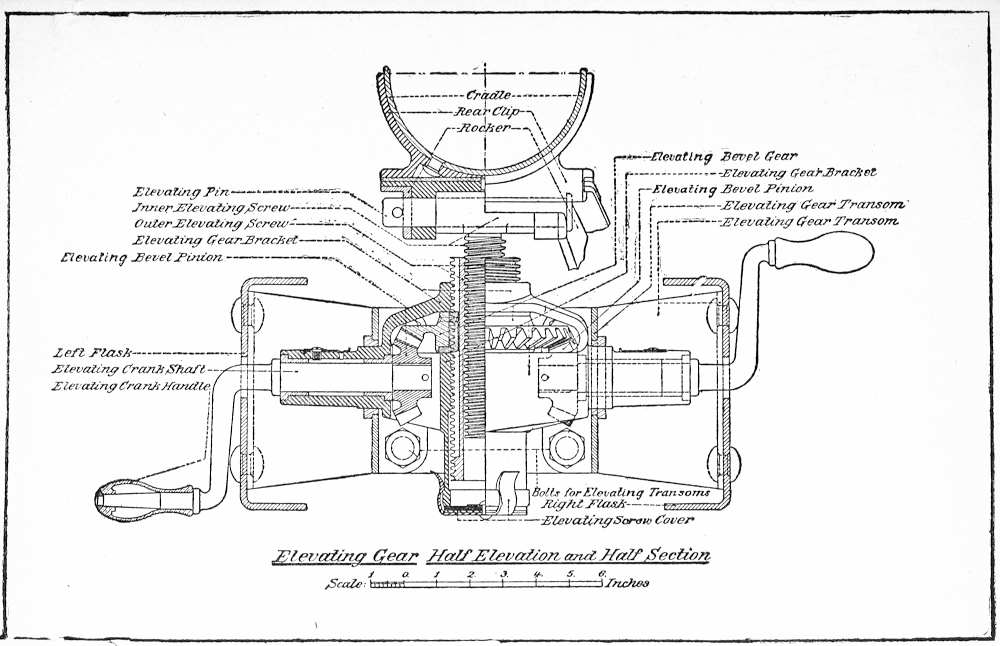

| Elevating Gear | 67 | |

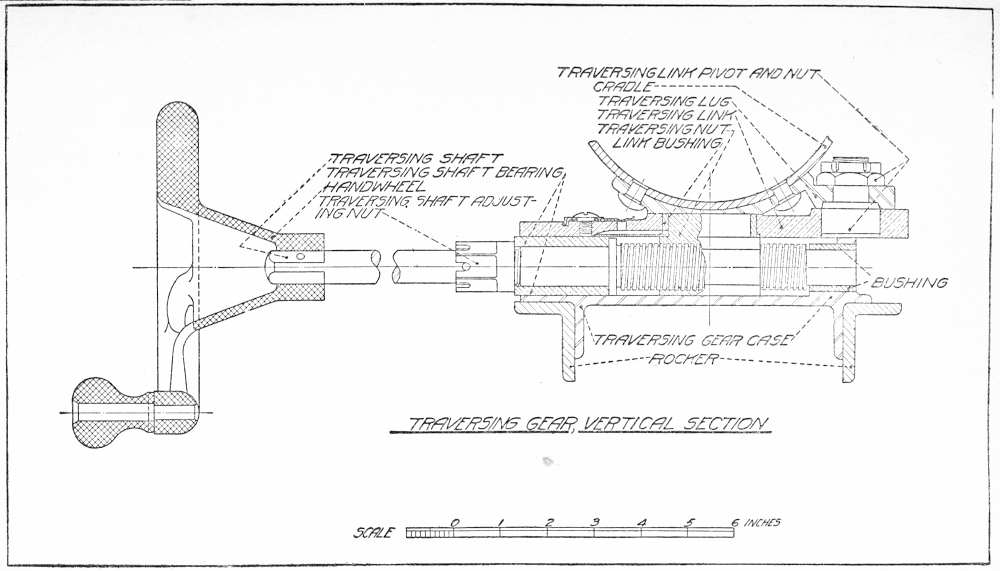

| Traversing Gear | Facing 66 | |

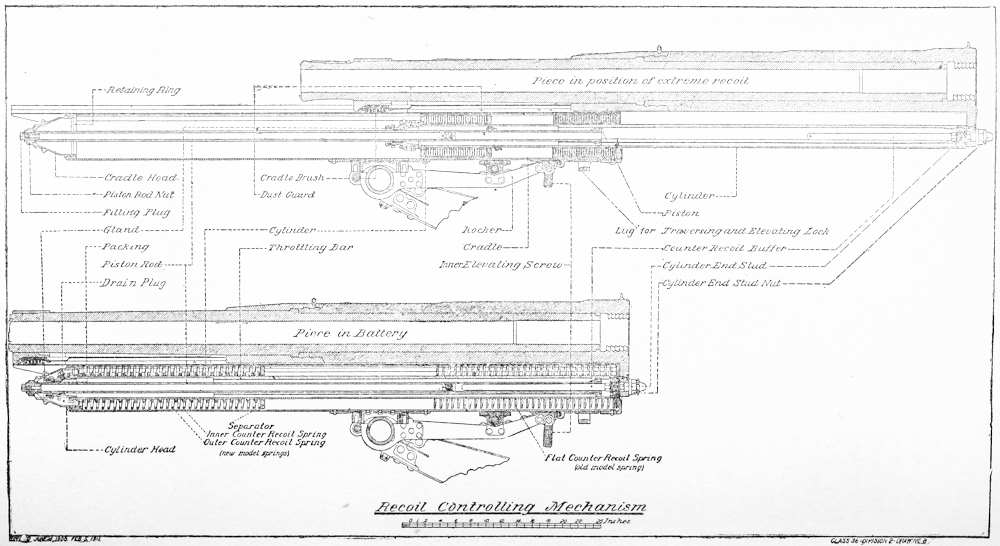

| Recoil Controlling Mechanism | Facing 69 | |

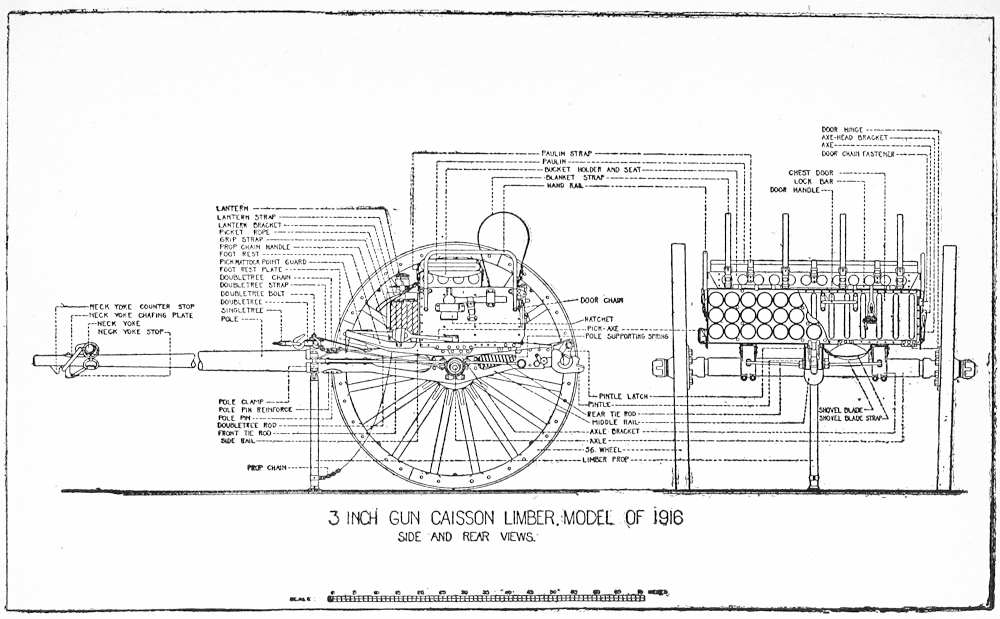

| Caisson Limber, Model 1916 | 73 | |

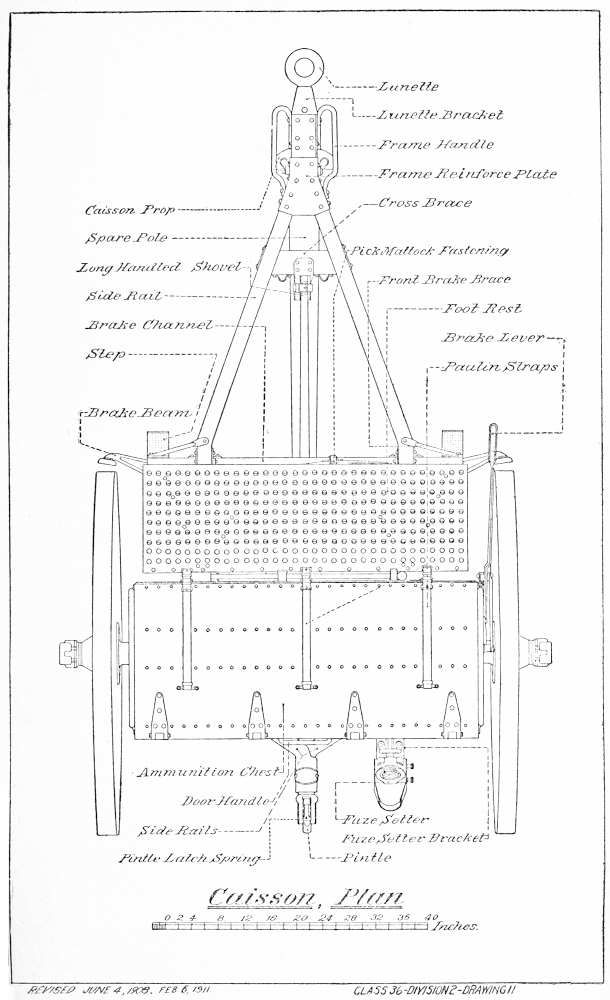

| Caisson, Model 1902 | Facing 74 | |

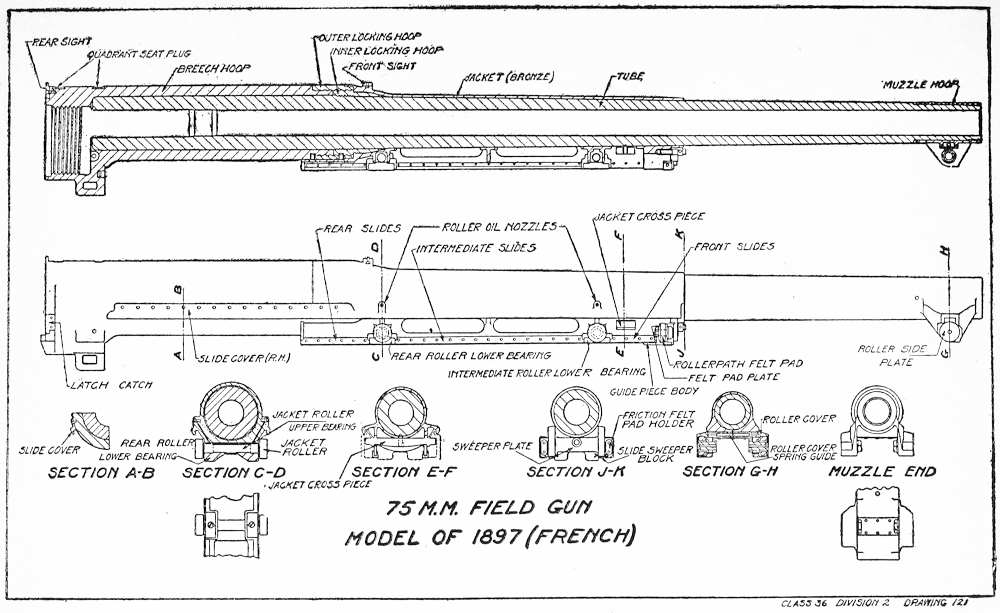

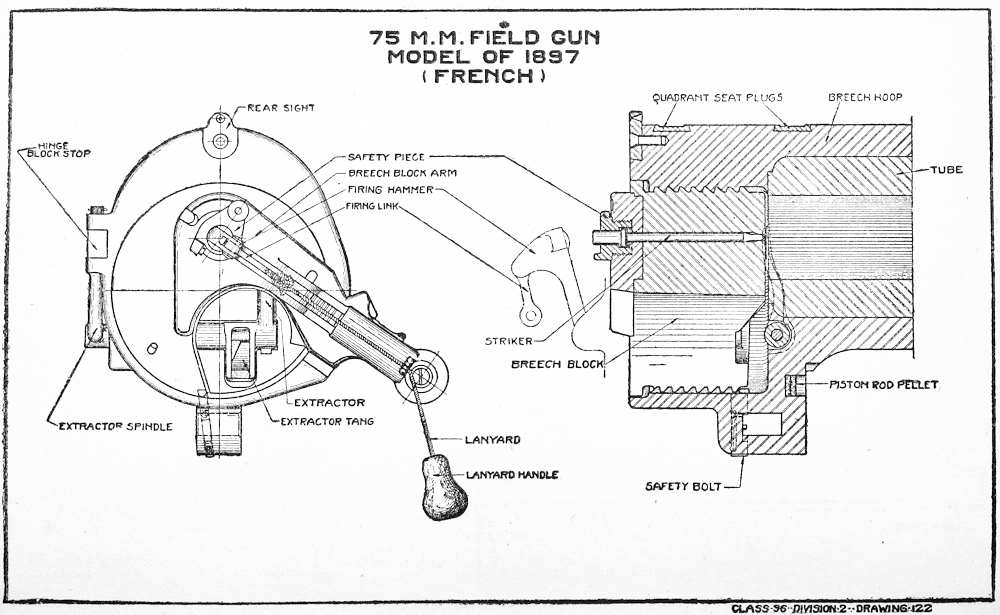

| 75-mm Field Gun, Model 1897 (French) | 85 | |

| Breech Mechanism | 86 | |

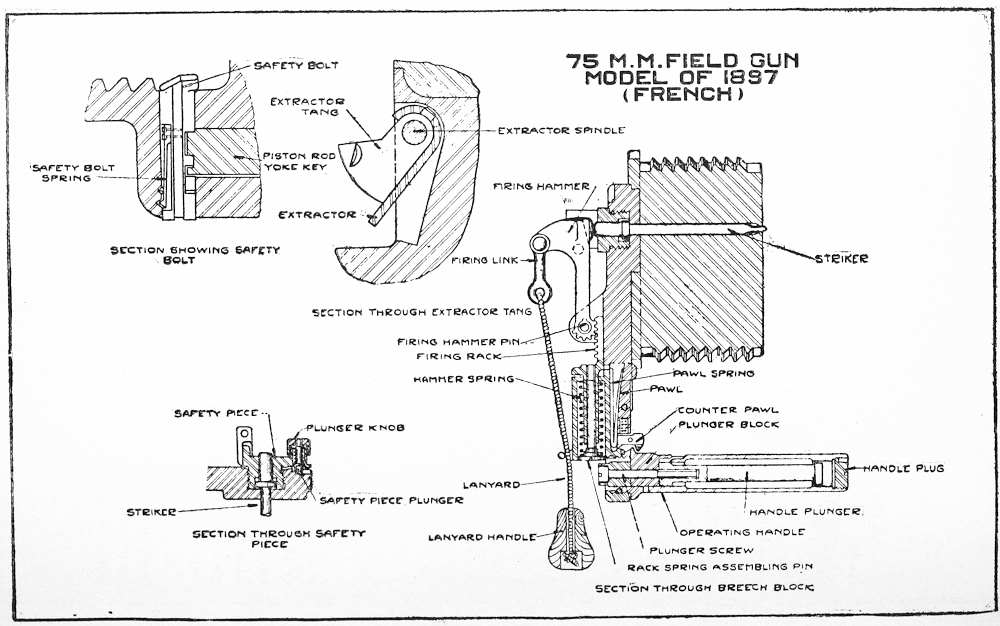

| Firing Mechanism | 88 | |

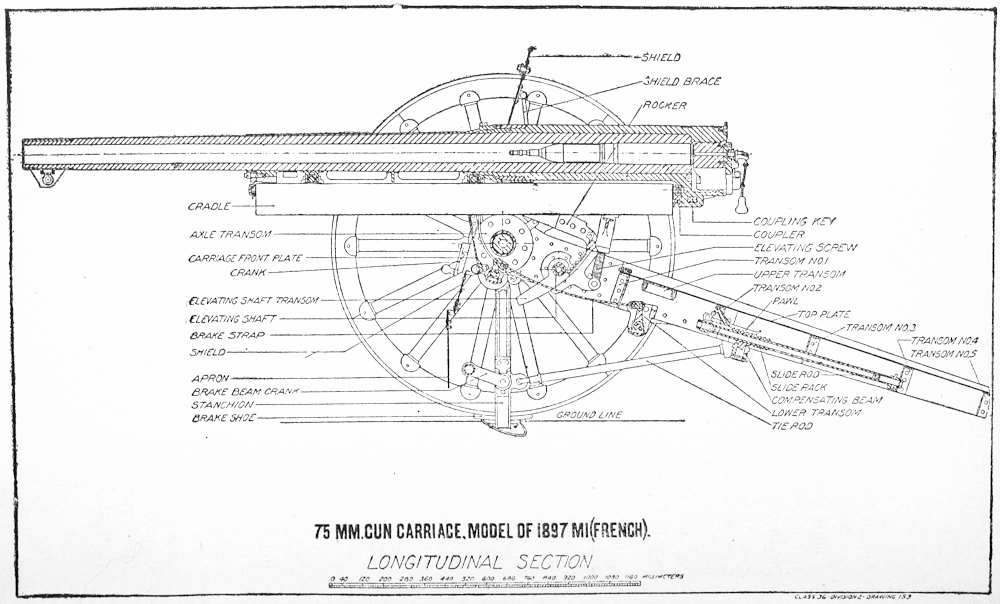

| Gun Carriage, Longitudinal Section | 90 | |

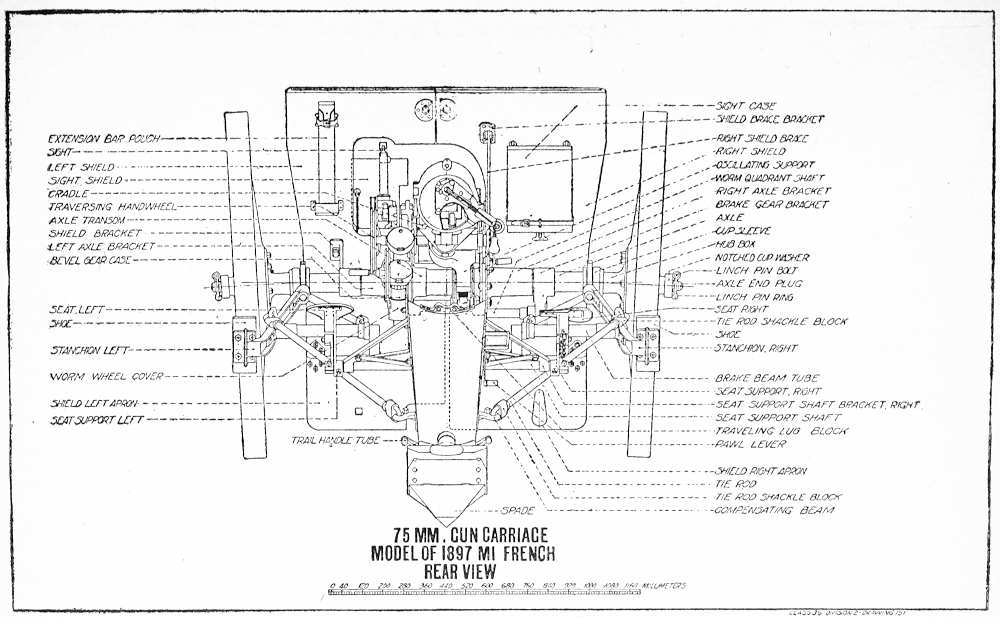

| Gun Carriage, Rear View | 91 | |

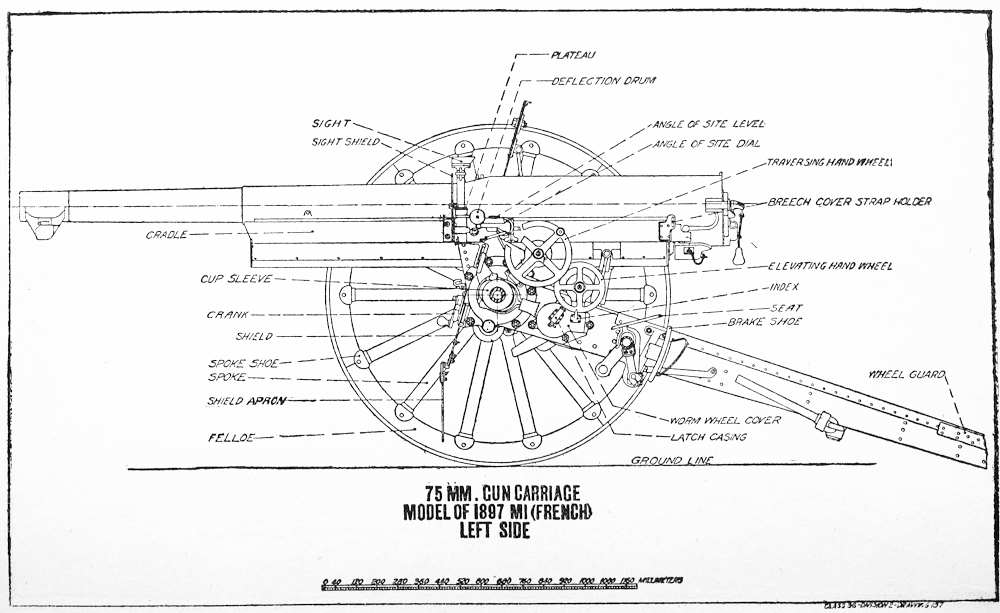

| Gun Carriage, Left Side | 92 | |

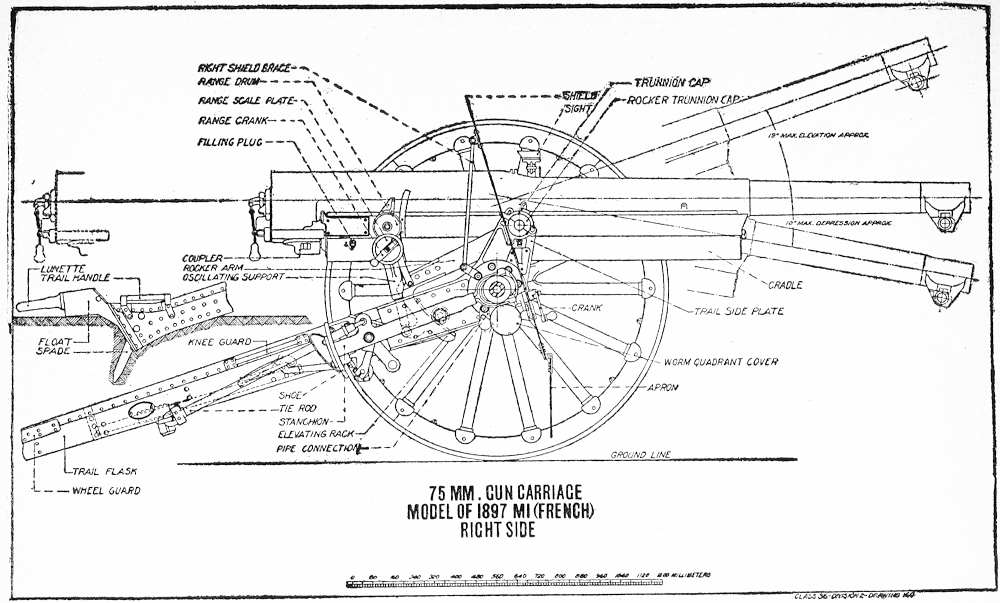

| Gun Carriage, Right Side | 93 | |

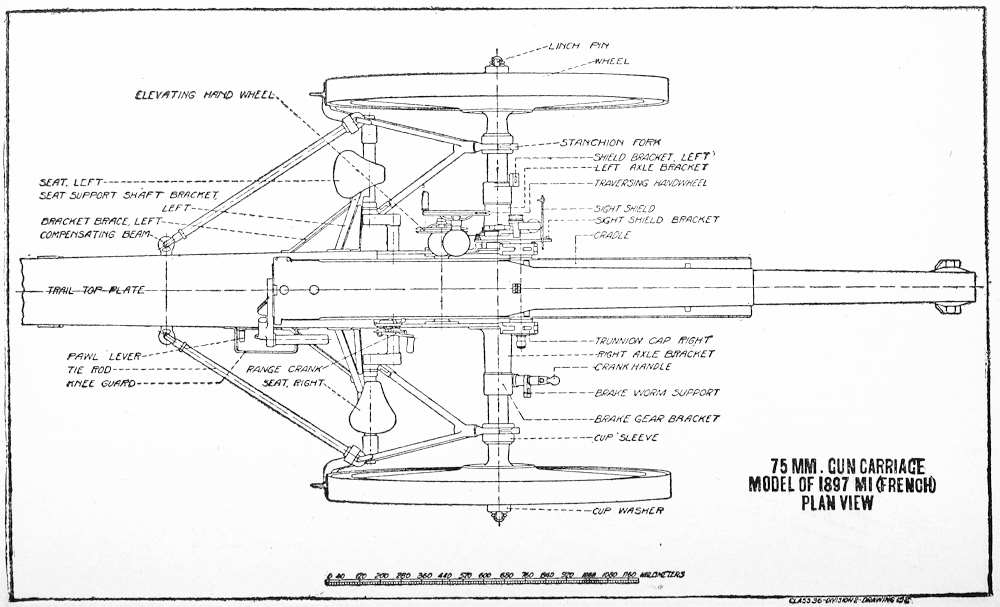

| Gun Carriage, Plan View | 94 | |

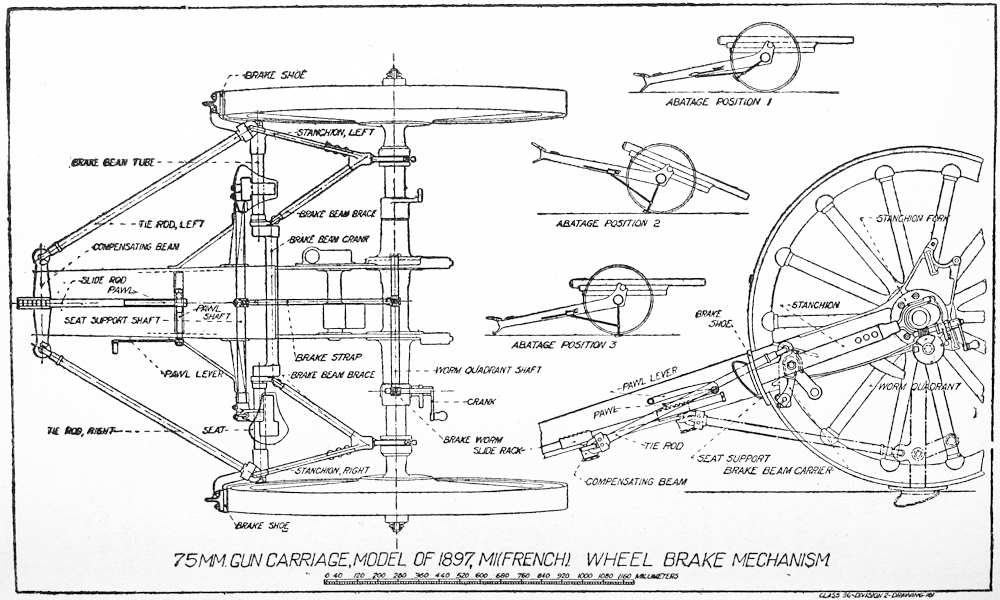

| Wheel Brake Mechanism (Abatage) | 96 | |

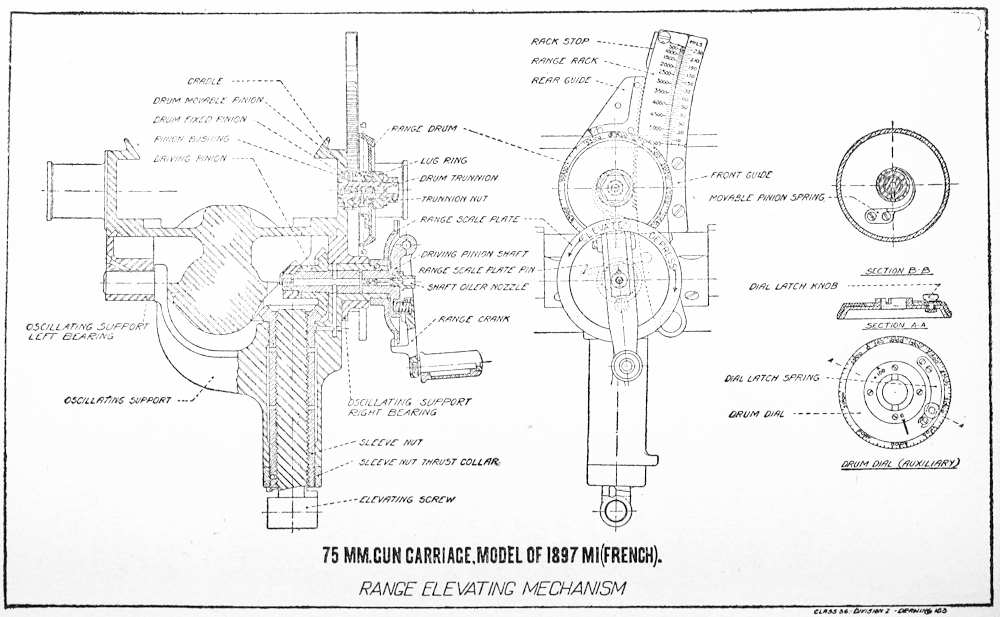

| Range Elevating Mechanism | 98 | |

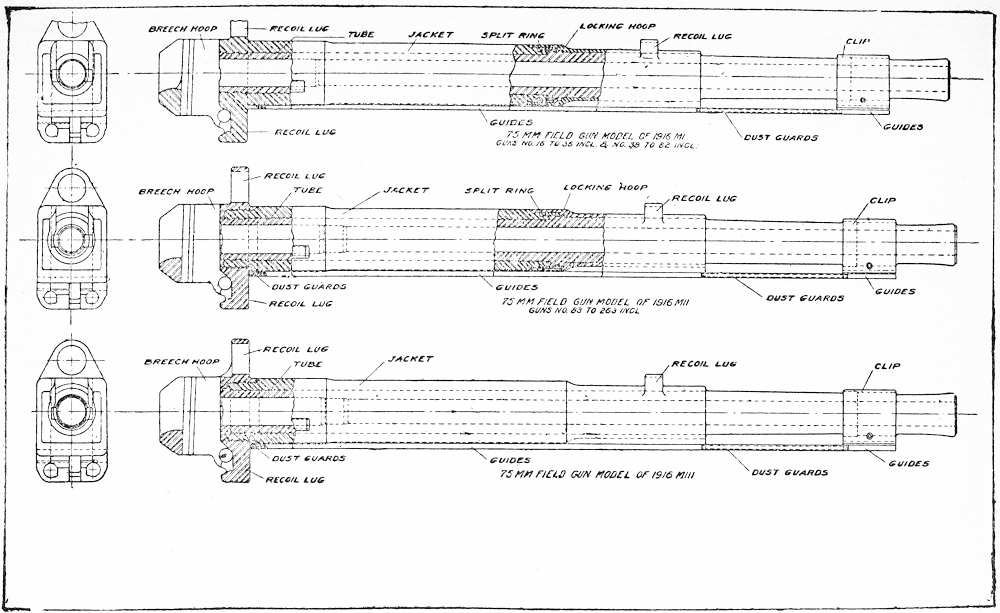

| 75-mm Field Gun, Model 1916 (American) | 107 | |

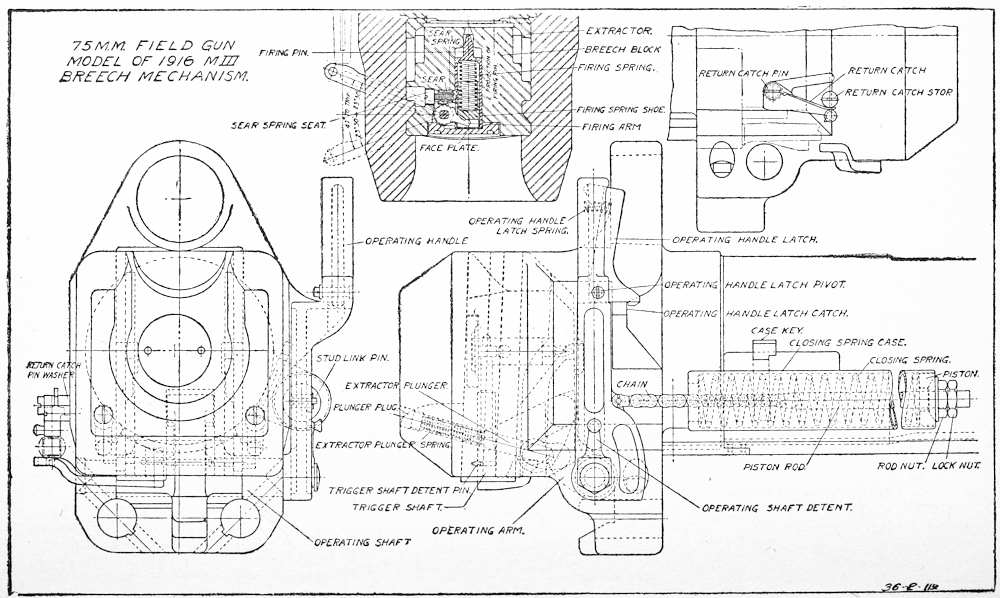

| Breech Mechanism | 108 | |

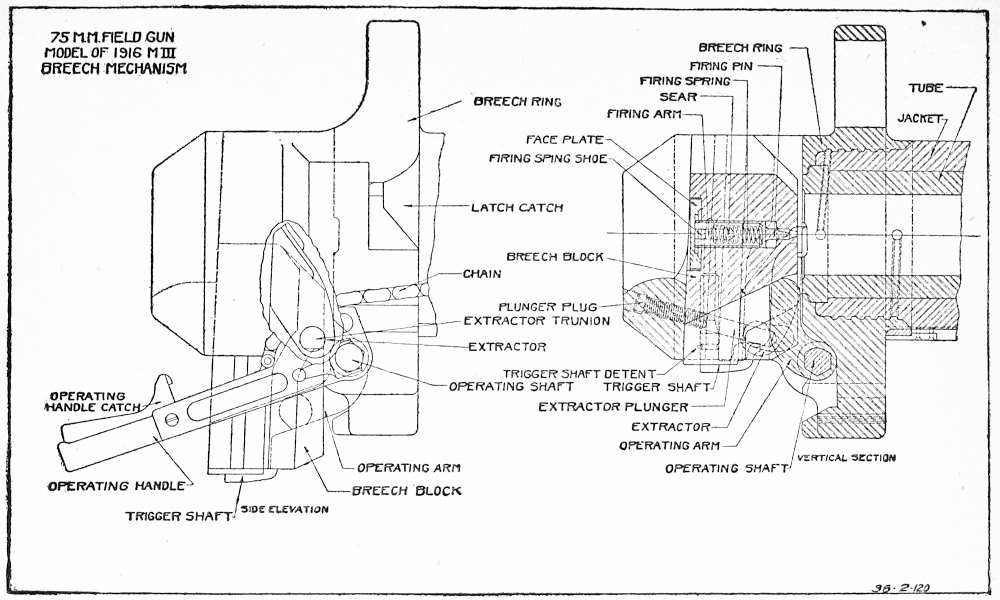

| Breech Mechanism | 109 | |

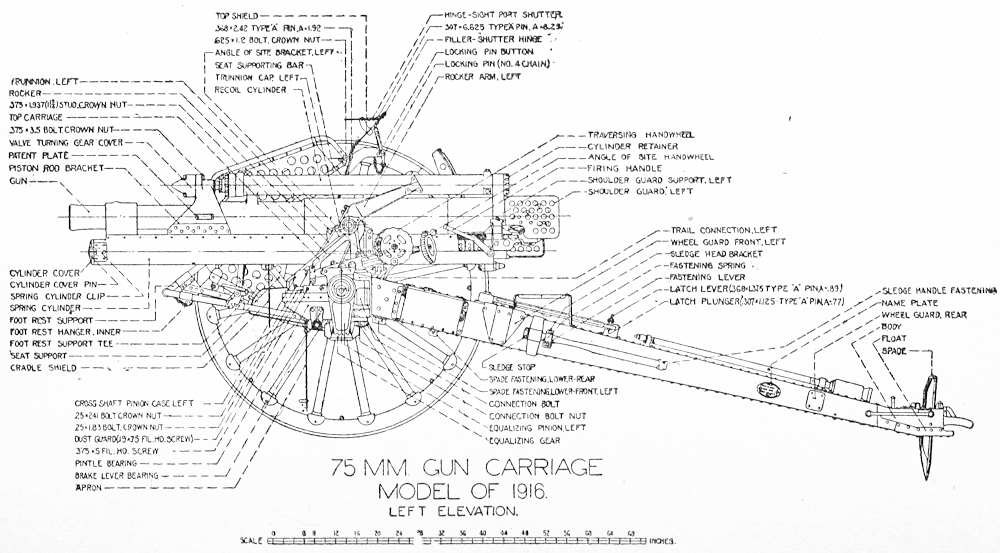

| Gun Carriage, Left Side | 112 | |

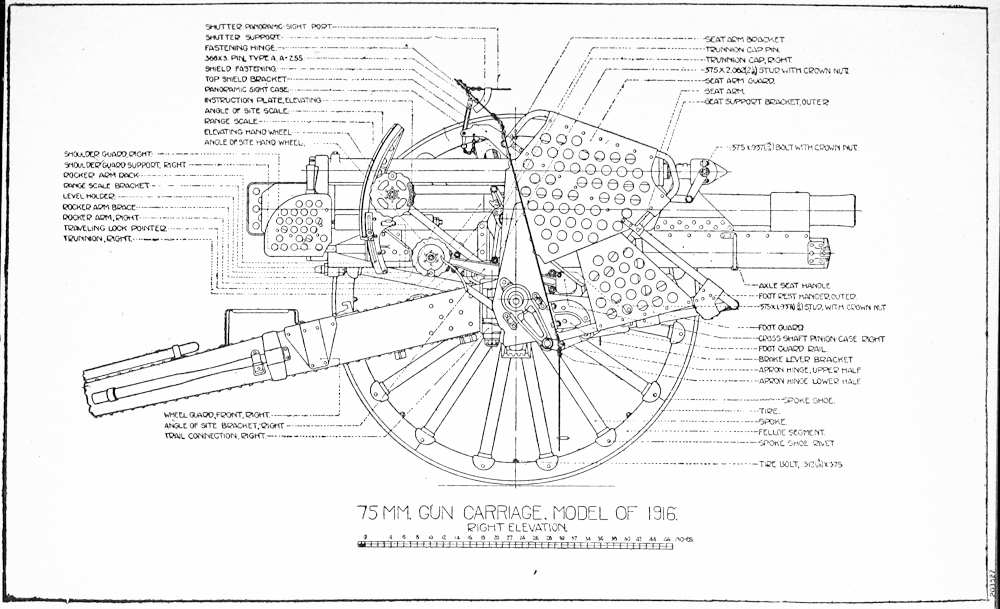

| Gun Carriage, Right Side | 113 | |

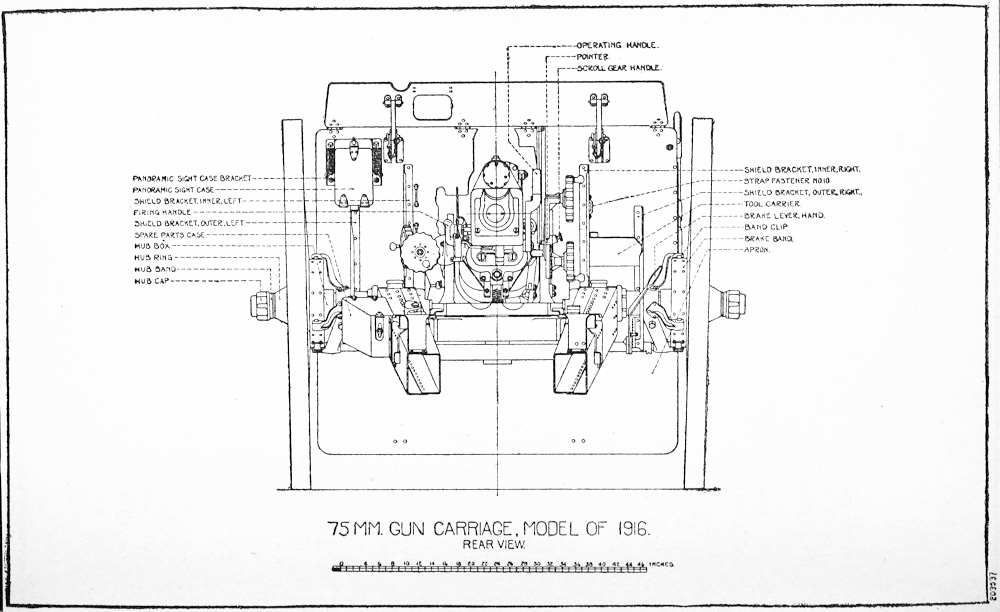

| Gun Carriage, Rear View | 116 | |

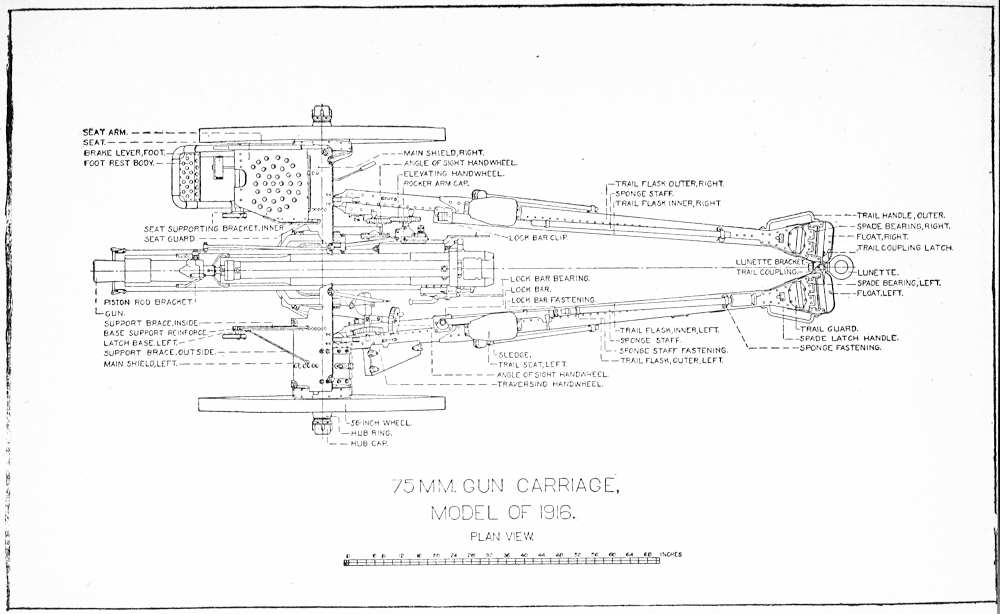

| Gun Carriage, Plan View | 117 | |

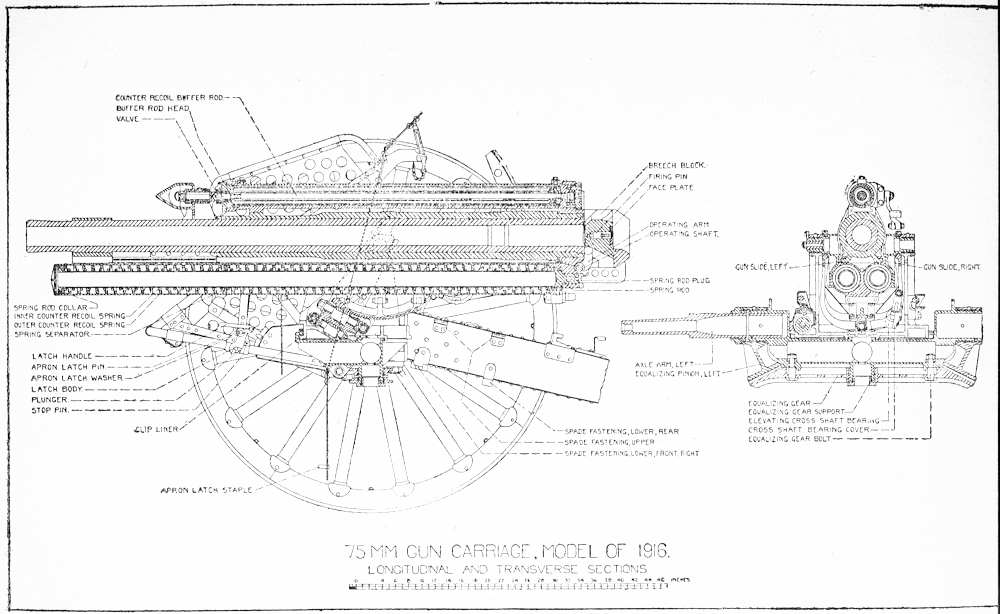

| Gun Carriage, Longitudinal and Transversal Sections | 119 | |

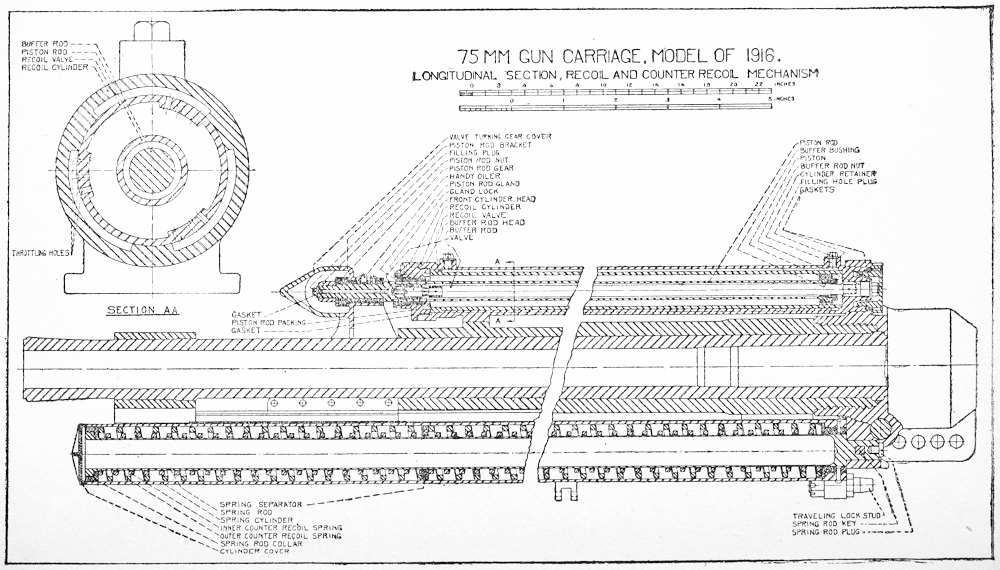

| Recoil Mechanism | 122 | |

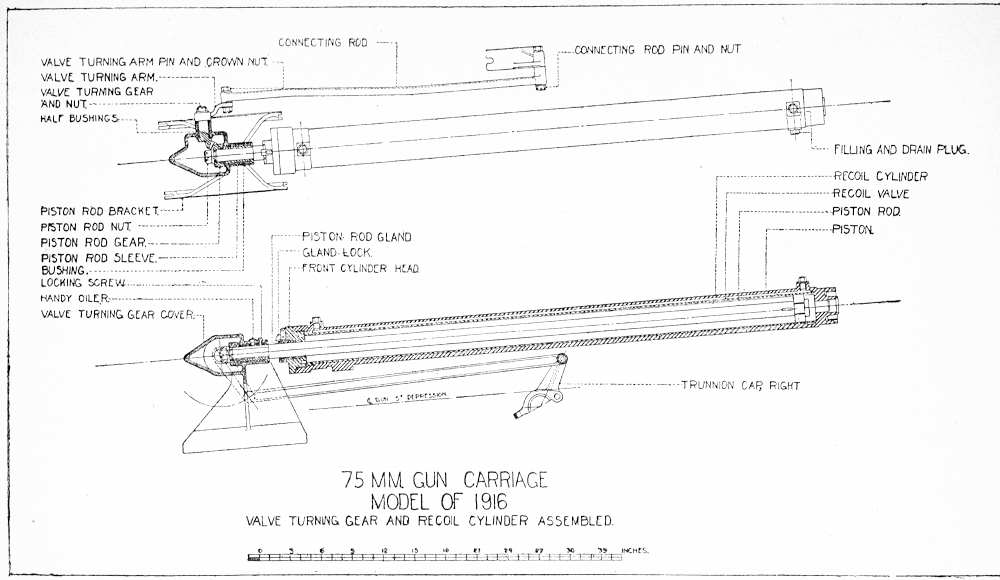

| Valve Turning Gear | 125 | |

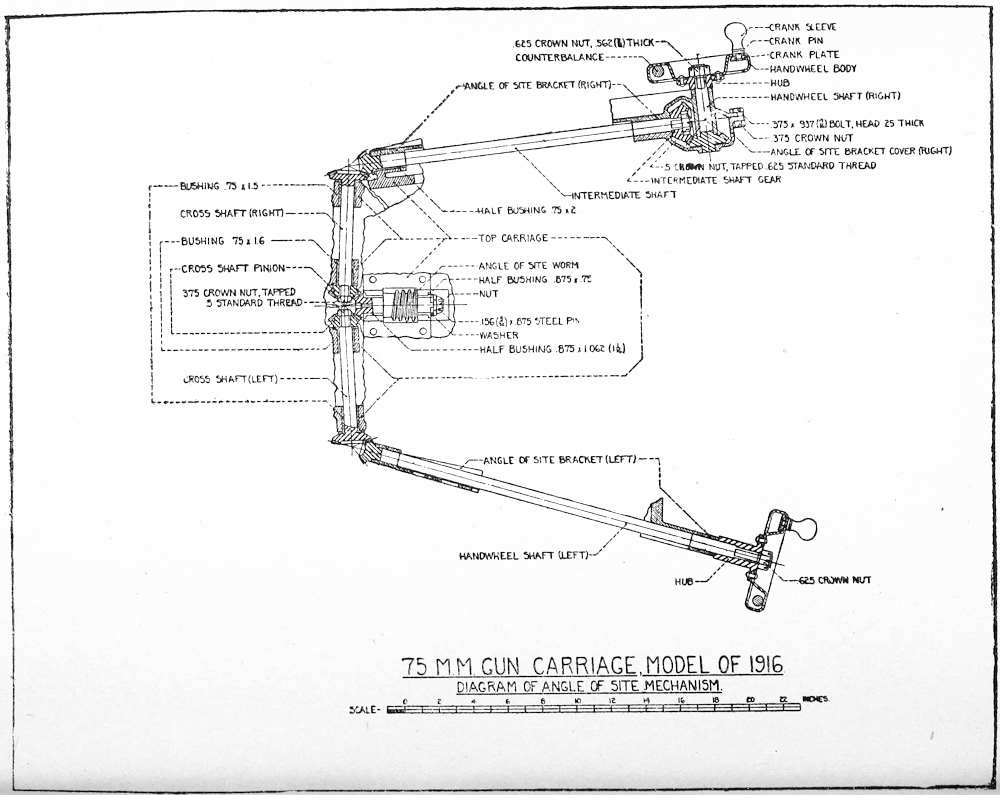

| Angle of Site Mechanism | 128 | |

| Elevating Mechanism | 130 | |

| Traversing Mechanism | 132 | |

| 75-mm Field Gun, Model 1917 (British) | 148 | |

| Breech Mechanism | 149 | |

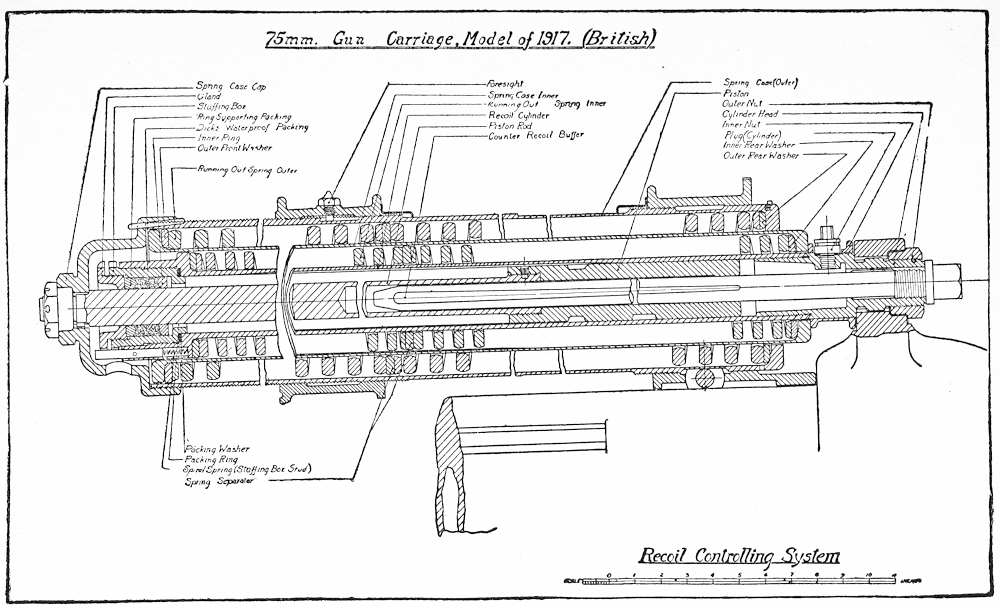

| Recoil Mechanism | 151 | |

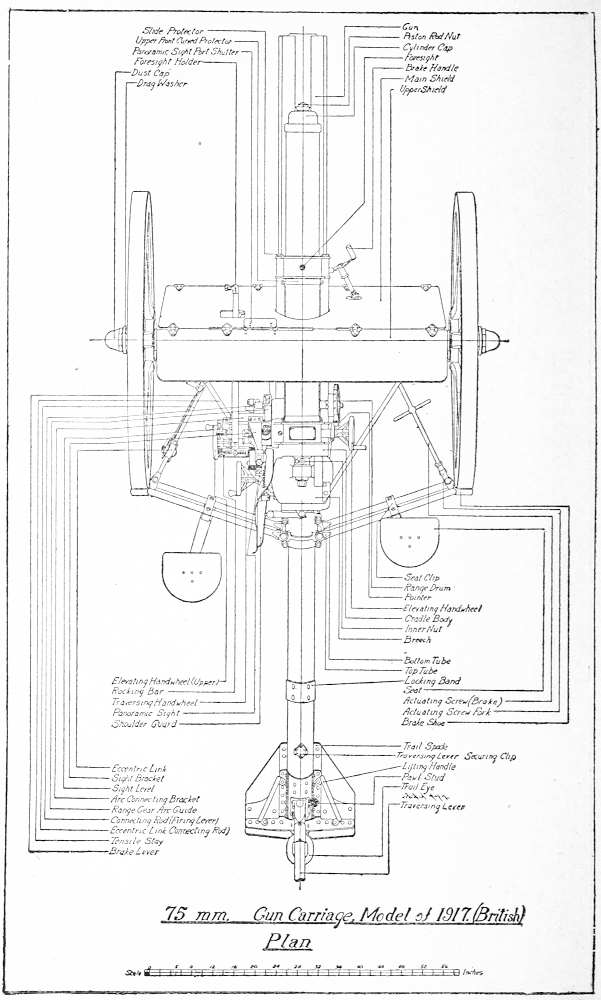

| Gun Carriage, Plan View | 152 | |

| 4.7-inch Gun, Model 1906, Longitudinal Section | 155 | |

| Gun Carriage, Left, Plan and Rear Views | 158 | |

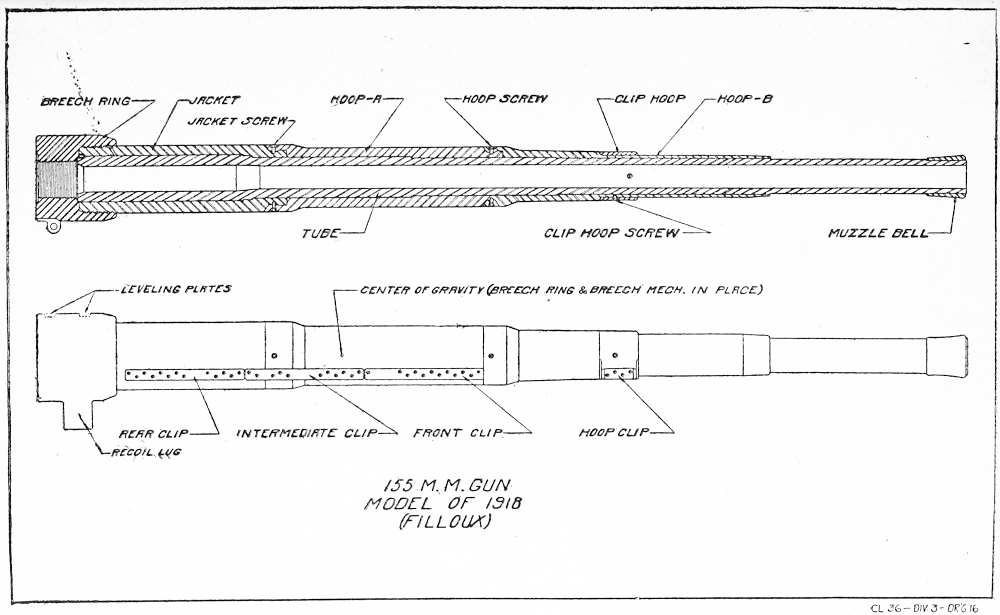

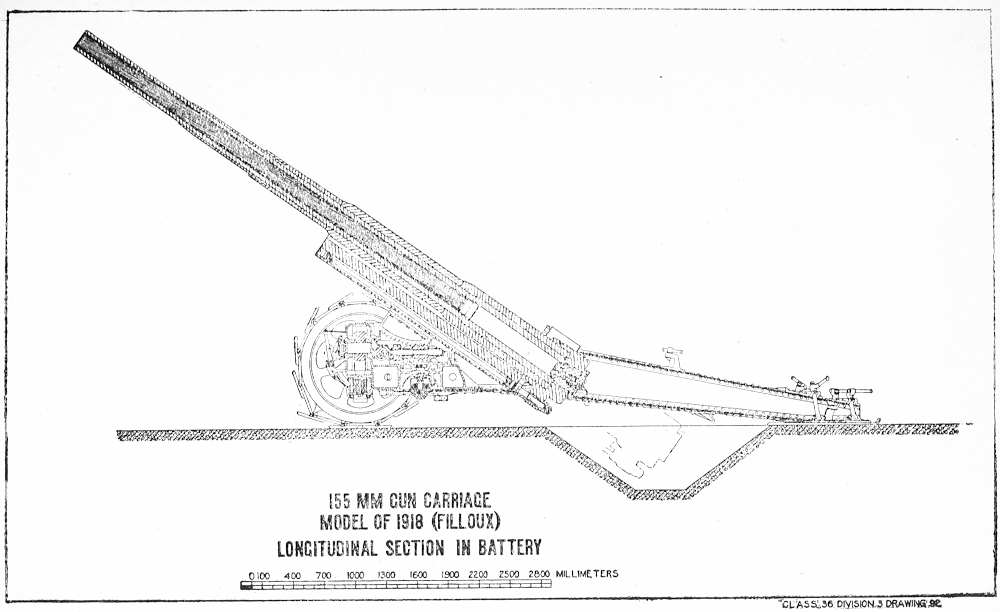

| 155-mm Gun, Model 1918, (GPF) (Filloux) | 161 | |

| Longitudinal Section in Battery | 163 | |

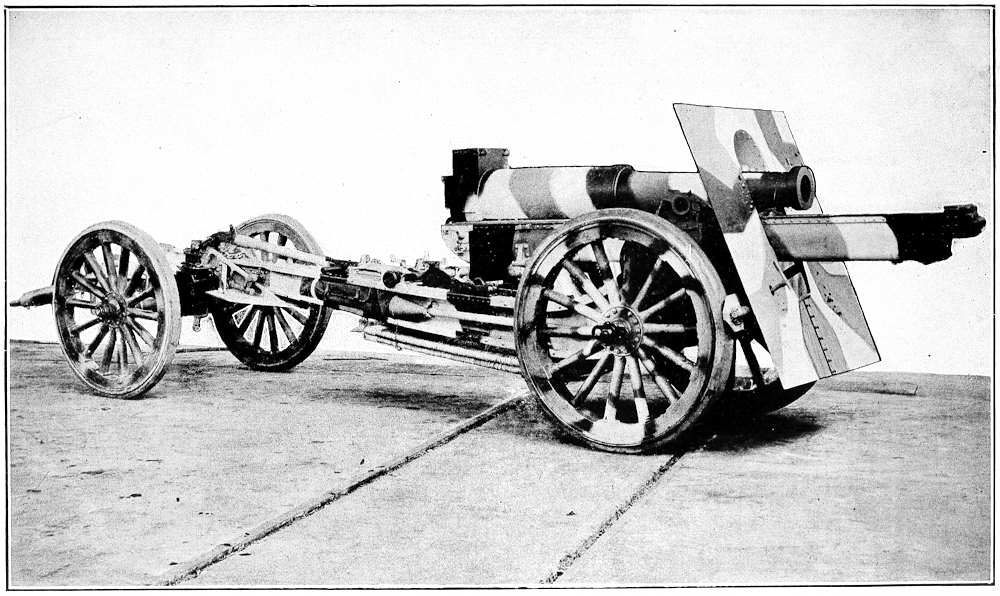

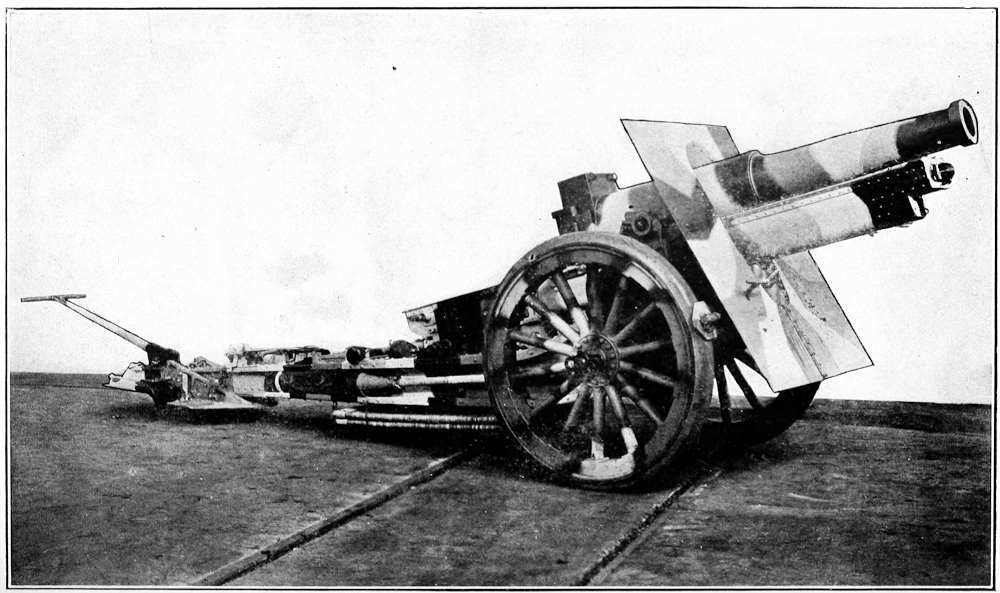

| Carriage and Limber, Traveling Position | Facing 165 | |

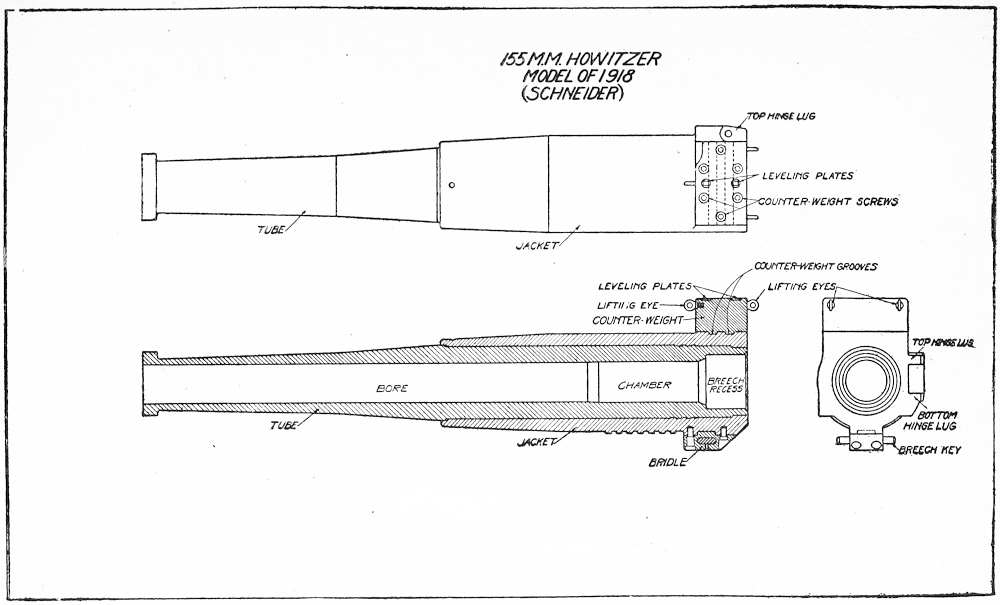

| 155-mm Howitzer, Model 1918 | 169 | |

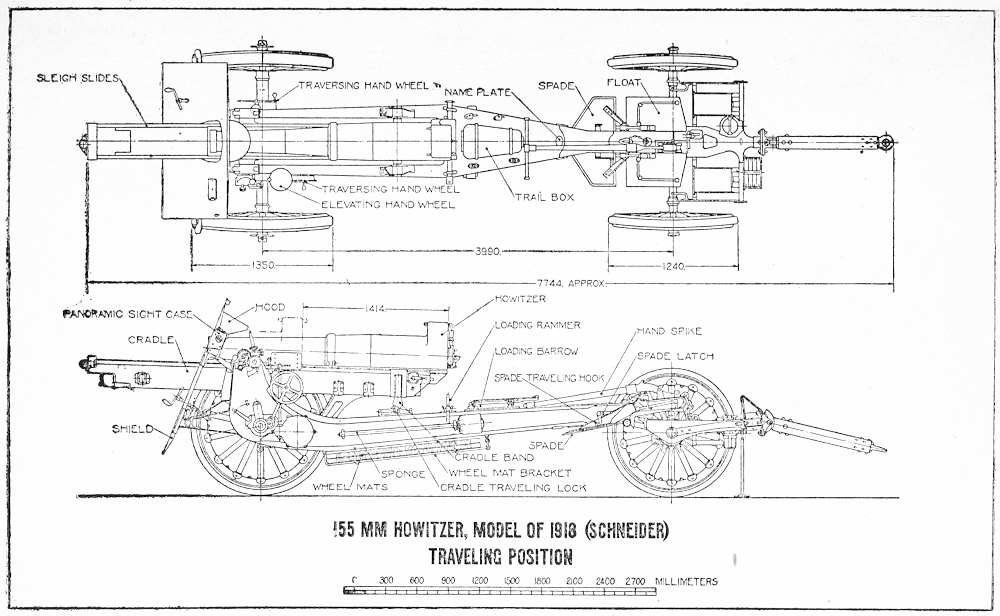

| Carriage and Limber | Facing 166[Pg 10] | |

| Carriage Unlimbered | Facing 167 | |

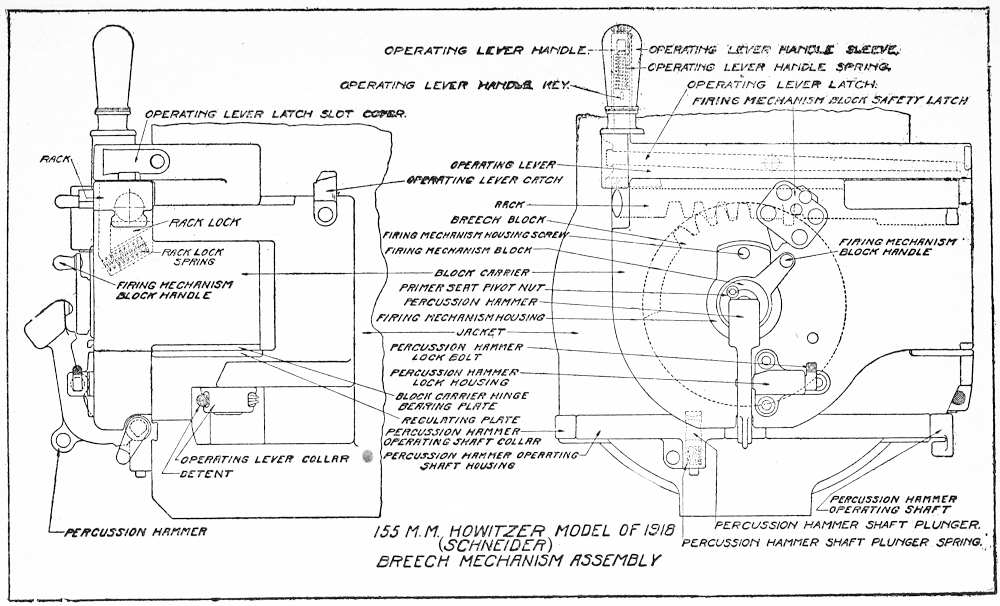

| Breech Mechanism | 171 | |

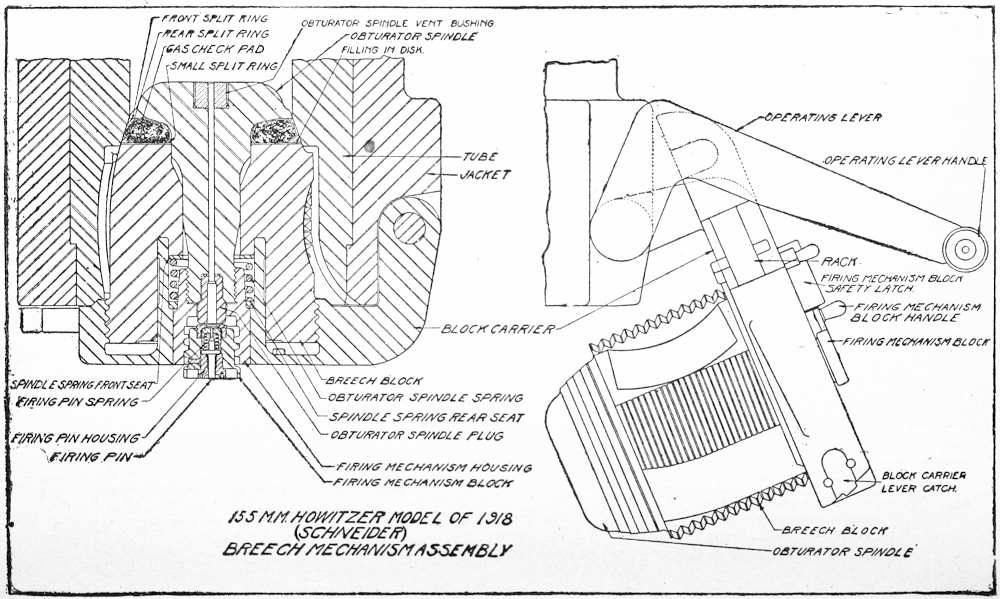

| Breech Mechanism | 172 | |

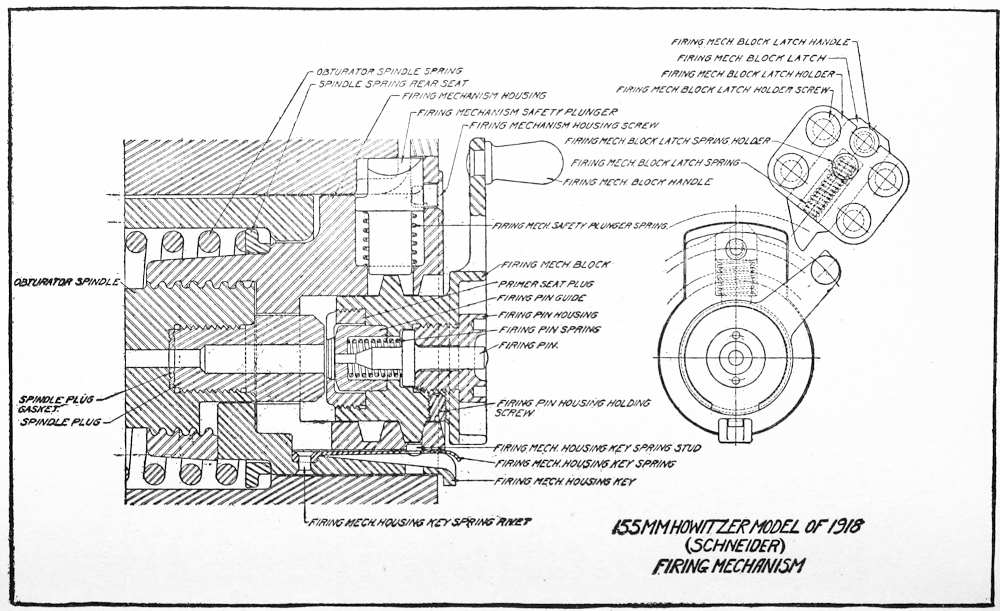

| Firing Mechanism | 174 | |

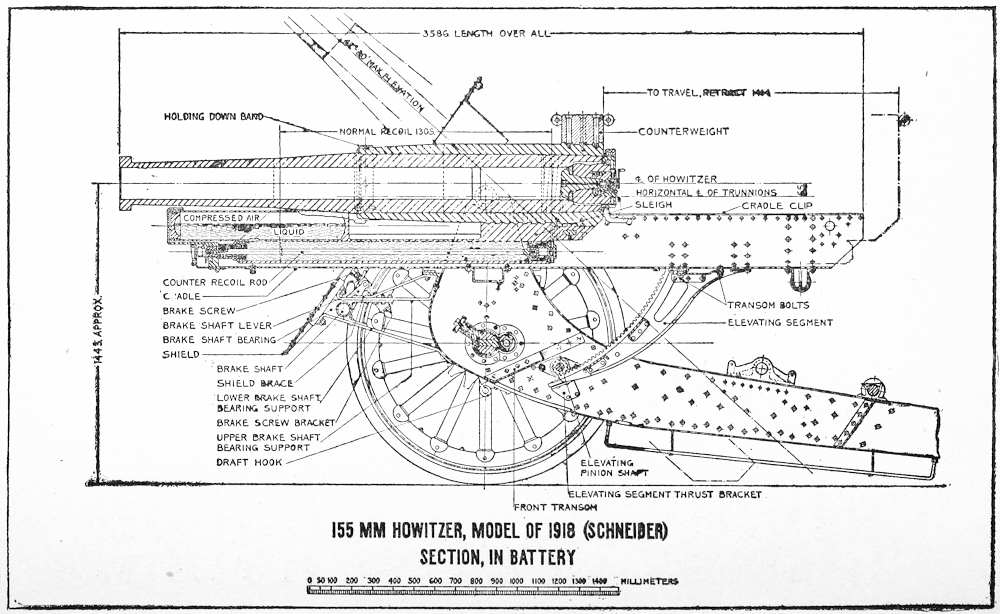

| Longitudinal Section | 180 | |

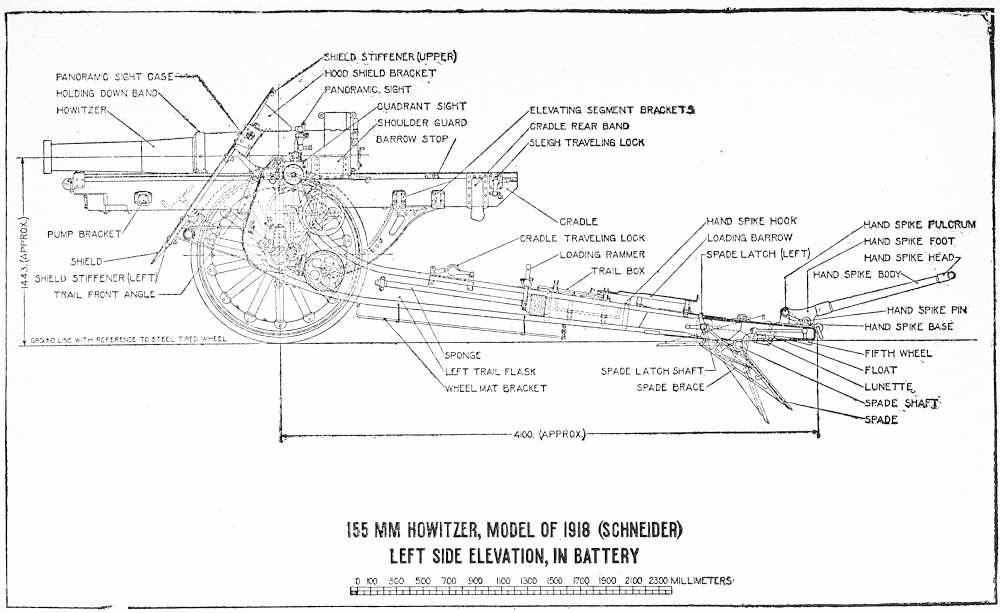

| Carriage, Left Side | 183 | |

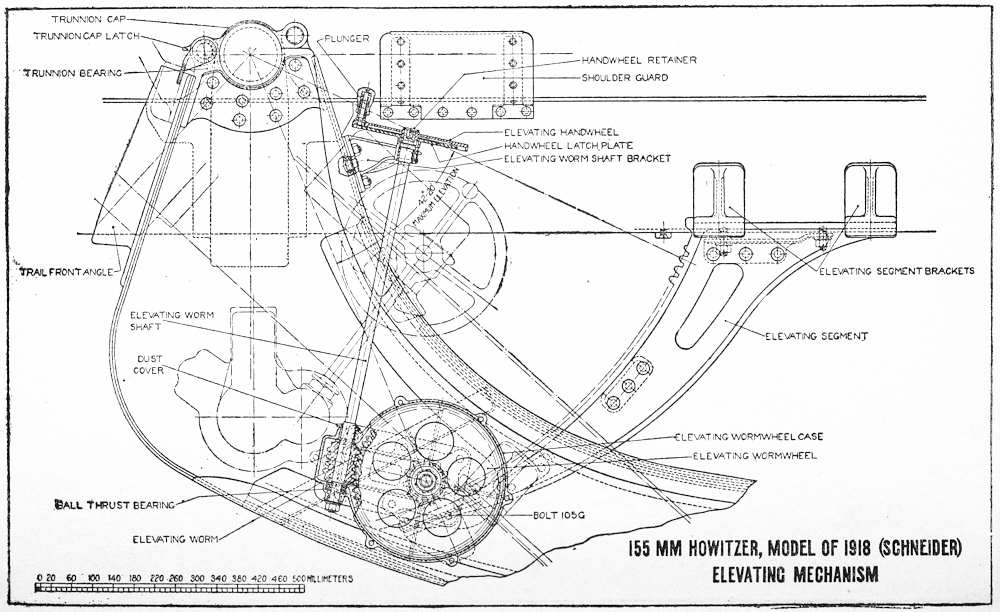

| Elevating Mechanism | 184 | |

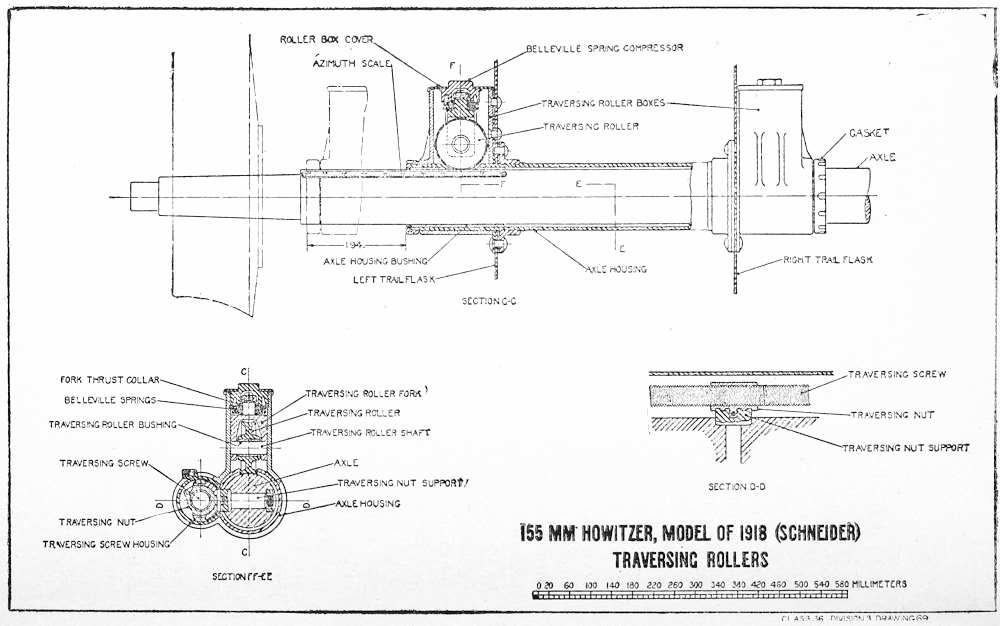

| Traversing Rollers | 186 | |

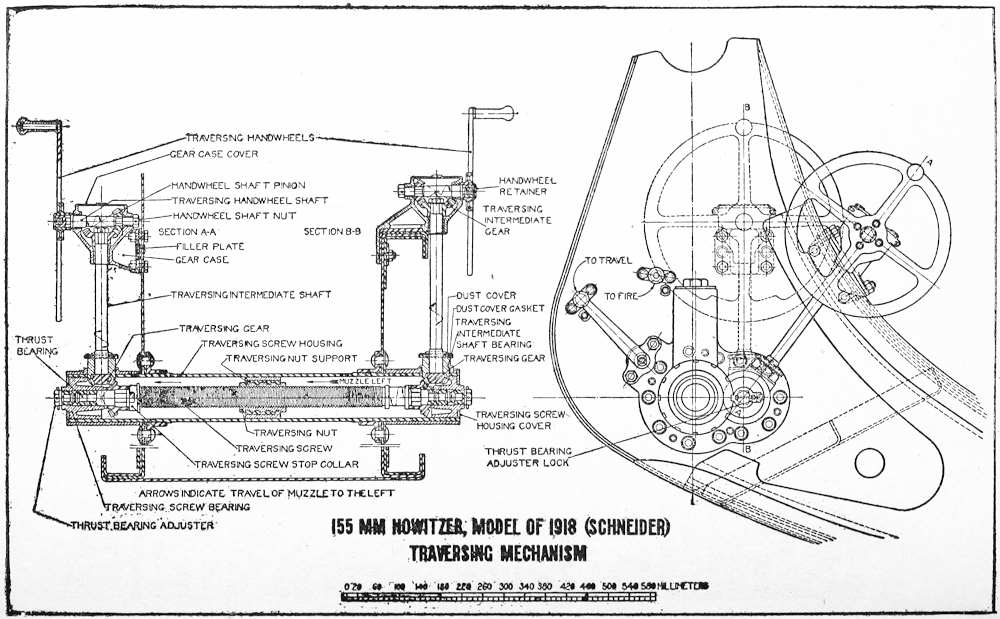

| Traversing Mechanism | 188 | |

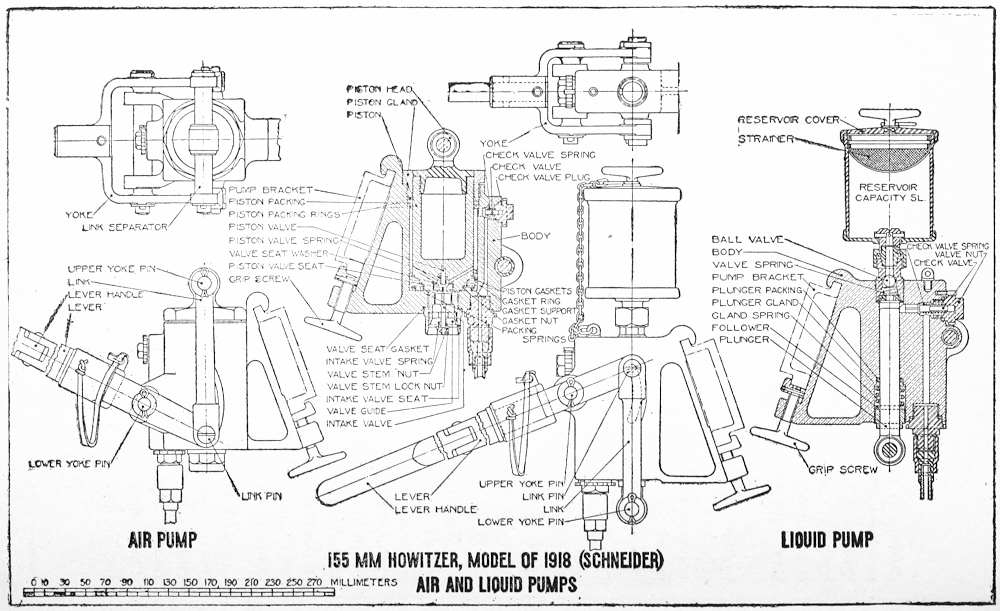

| Air and Liquid Pumps | 190 | |

| Howitzer Carriage, Plan View | 191 | |

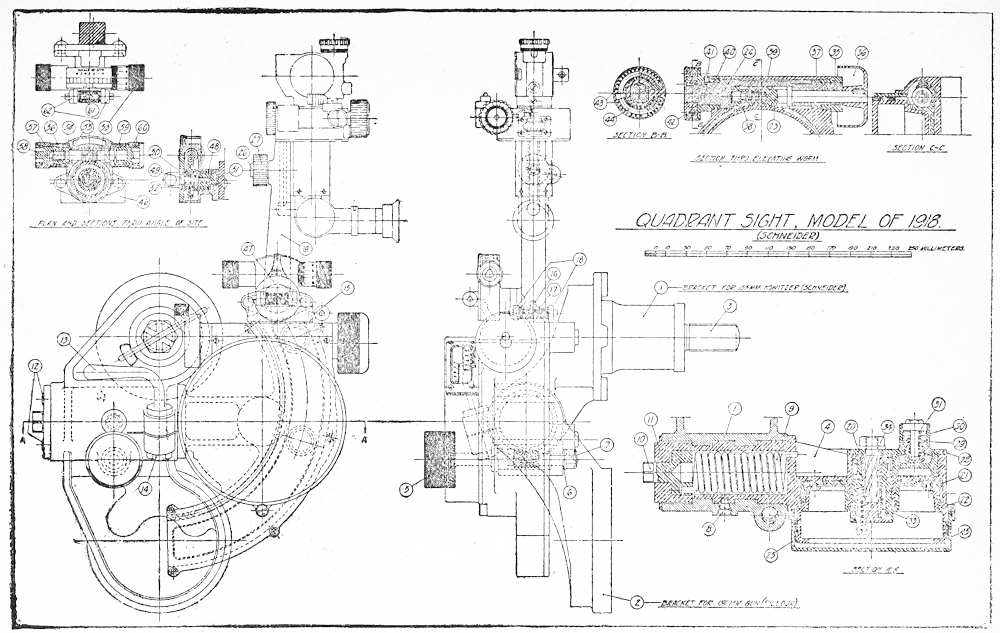

| Quadrant Sights, Model 1918 | 193 | |

| DeBange Obturator | 205 | |

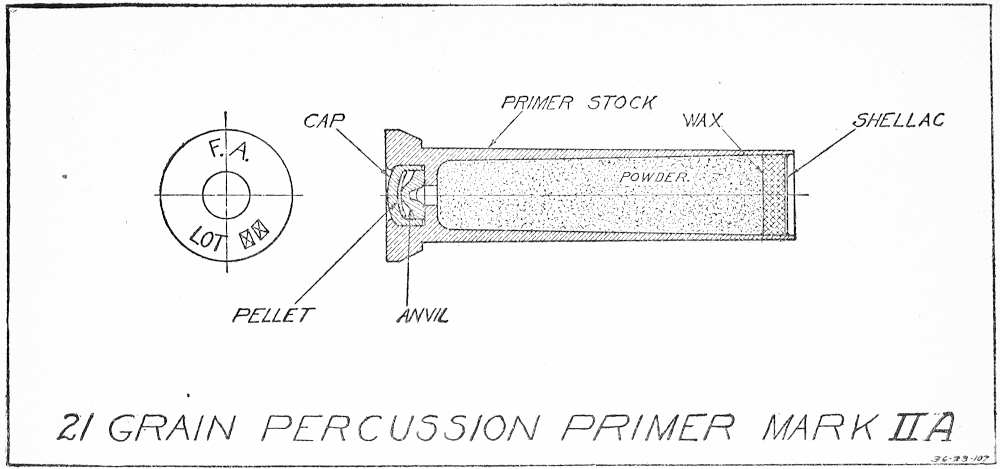

| Mark II-A Primer | 207 | |

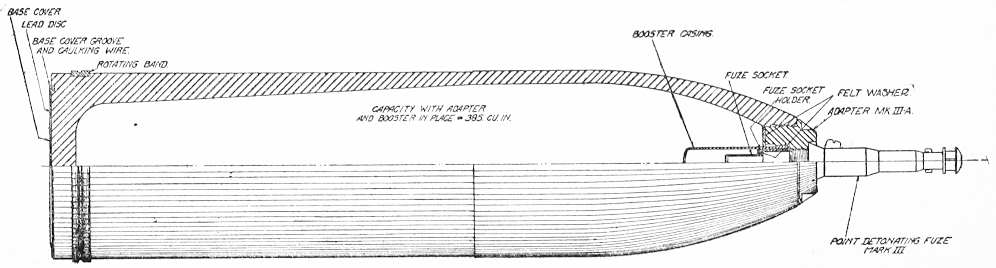

| 155 Steel Shell Mark IV | 210 | |

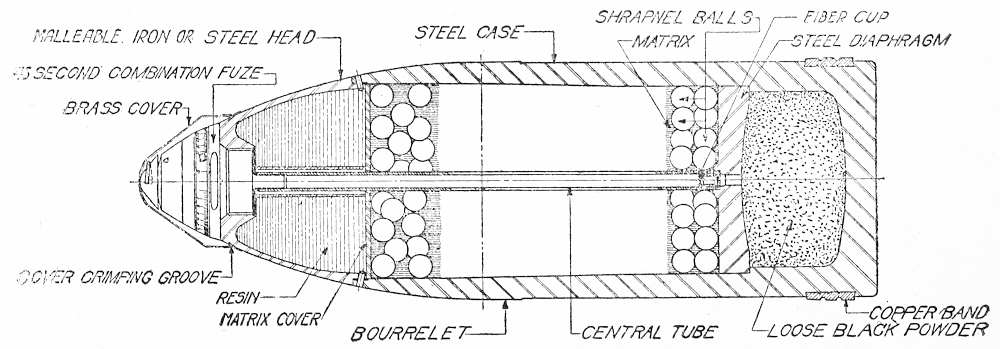

| 155 Shrapnel Mark I | 212 | |

| 4.7-inch Gun Ammunition | 213 | |

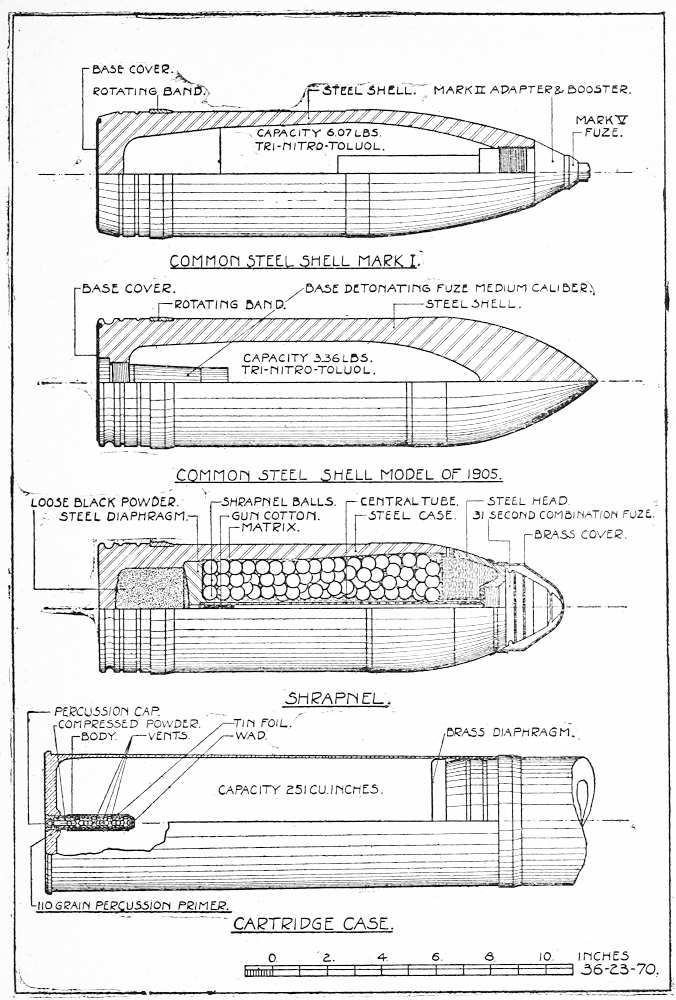

| 3-inch Gun Ammunition | Facing 214 | |

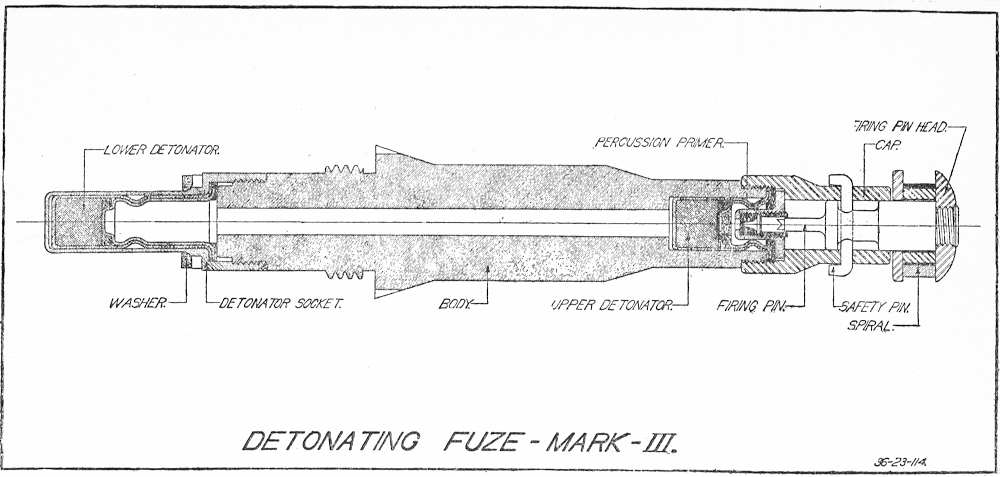

| Detonating Fuze, Mark III | 225 | |

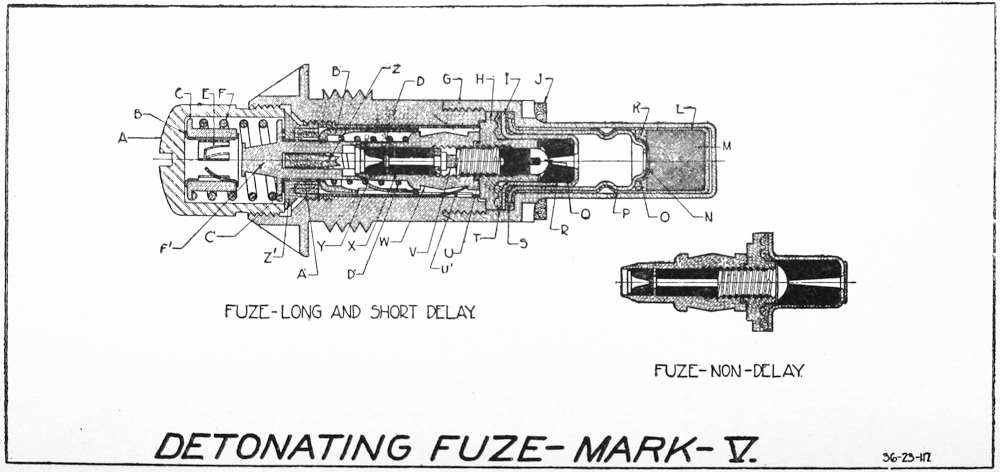

| Detonating Fuze, Mark V | 226 | |

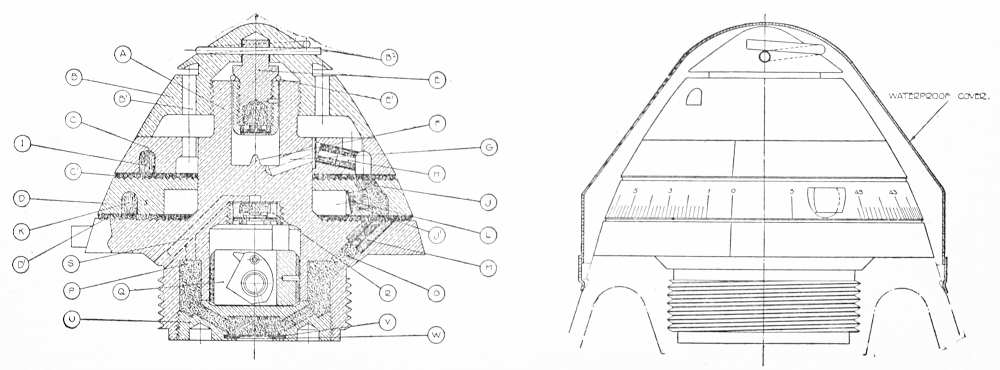

| 45 Second Combination Fuze, Mark 1 | 230 | |

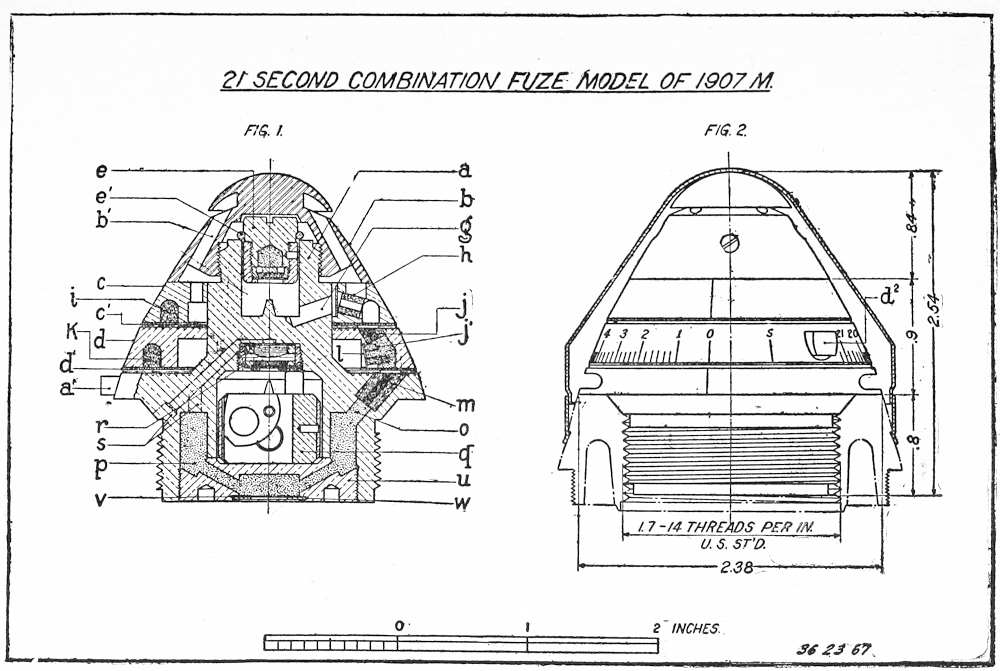

| 21 Second Combination Fuze, Model 1907 M | 231 | |

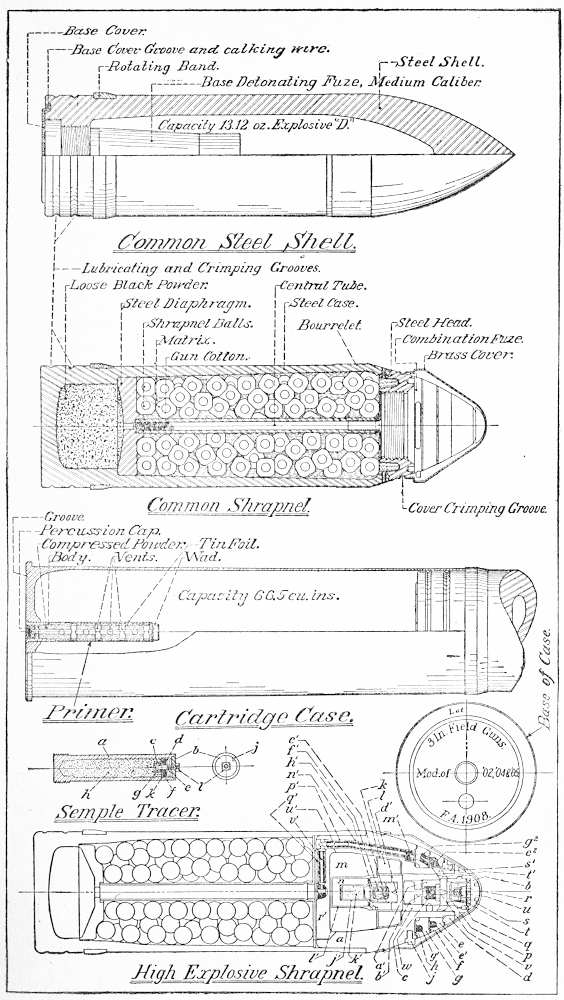

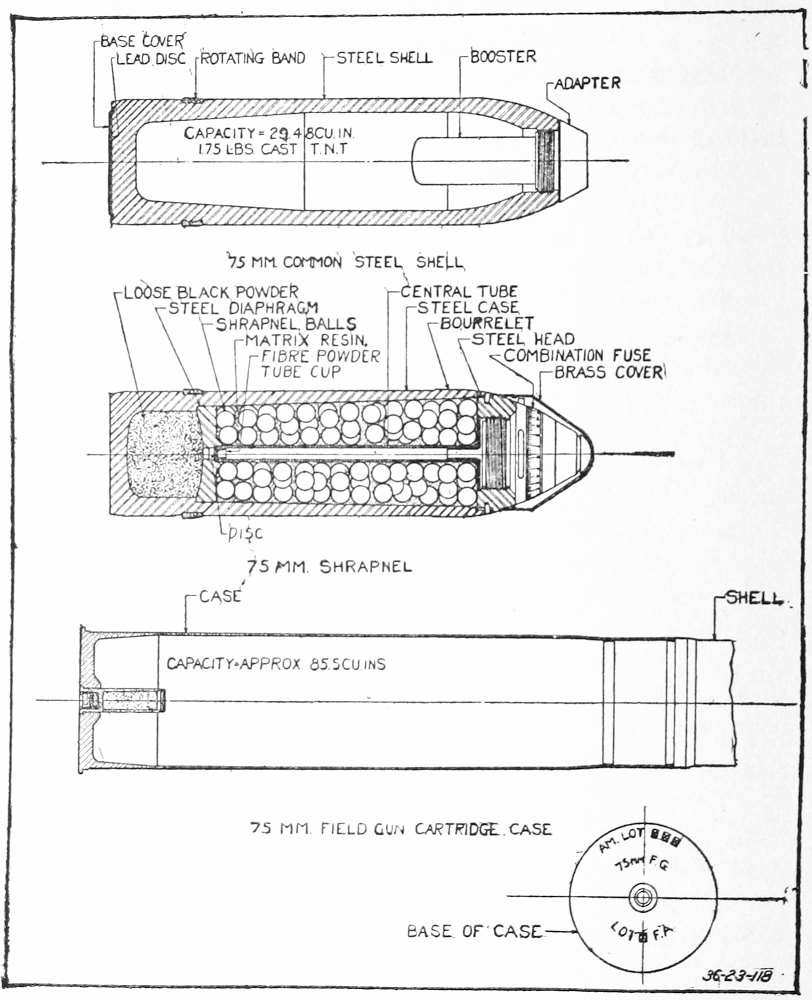

| 75-mm Gun Ammunition | 234 | |

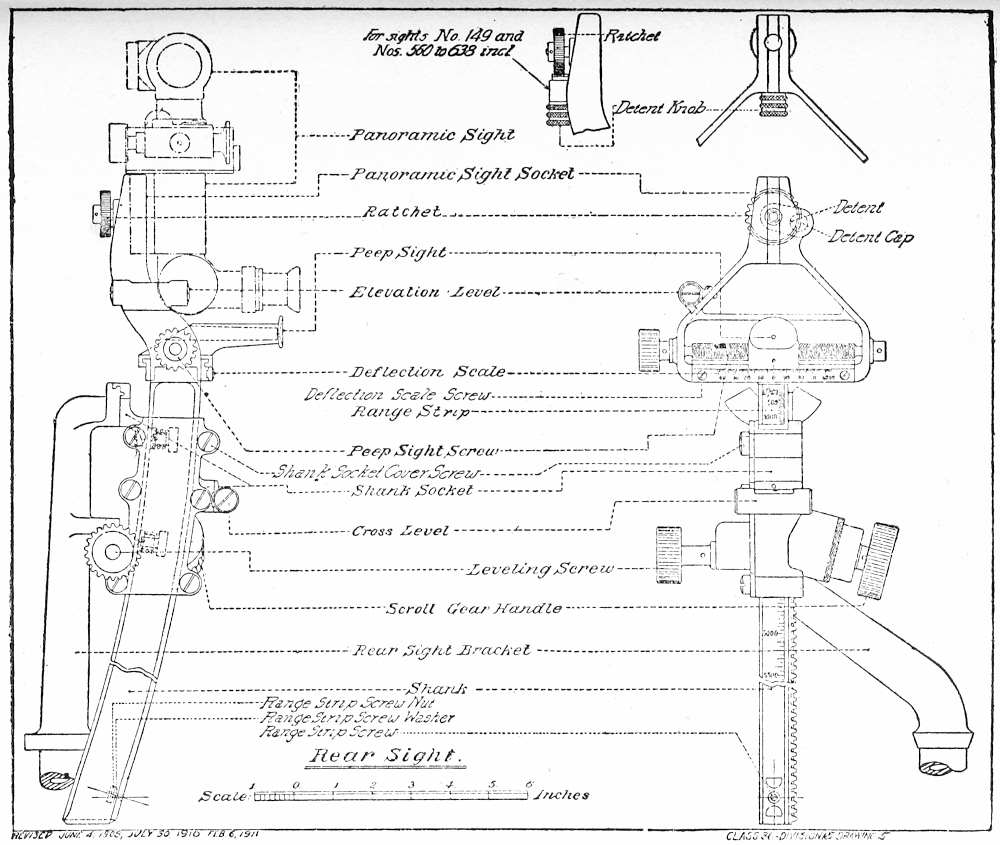

| Rear Sight, 3-inch Field Gun | 259 | |

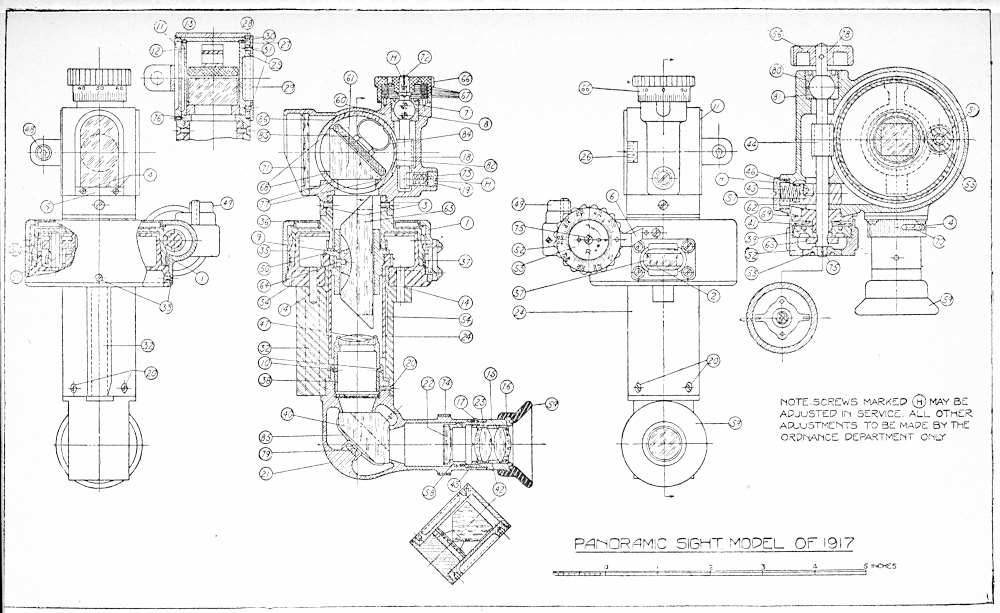

| Panoramic Sight, Model of 1917 | 261 | |

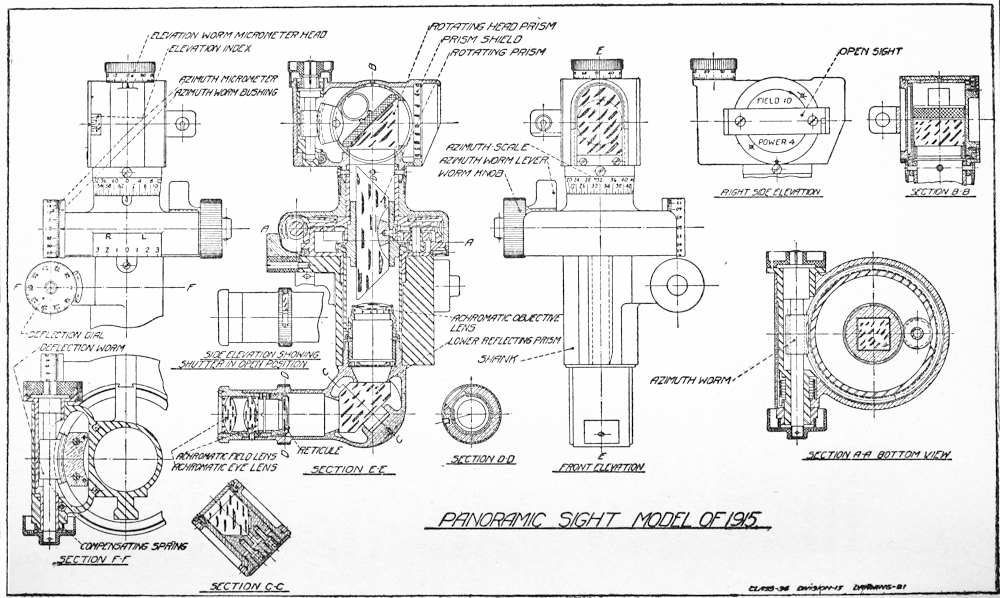

| Panoramic Sight, Model of 1915 | 264 | |

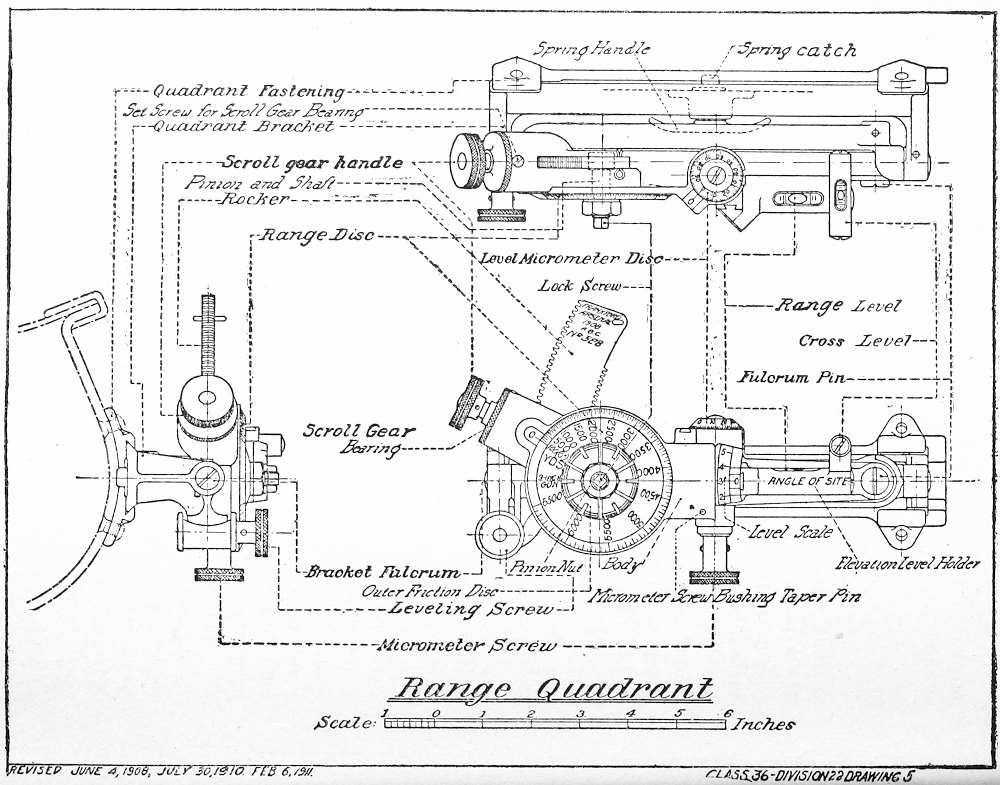

| Range Quadrant, 3-inch Field Gun | 266 | |

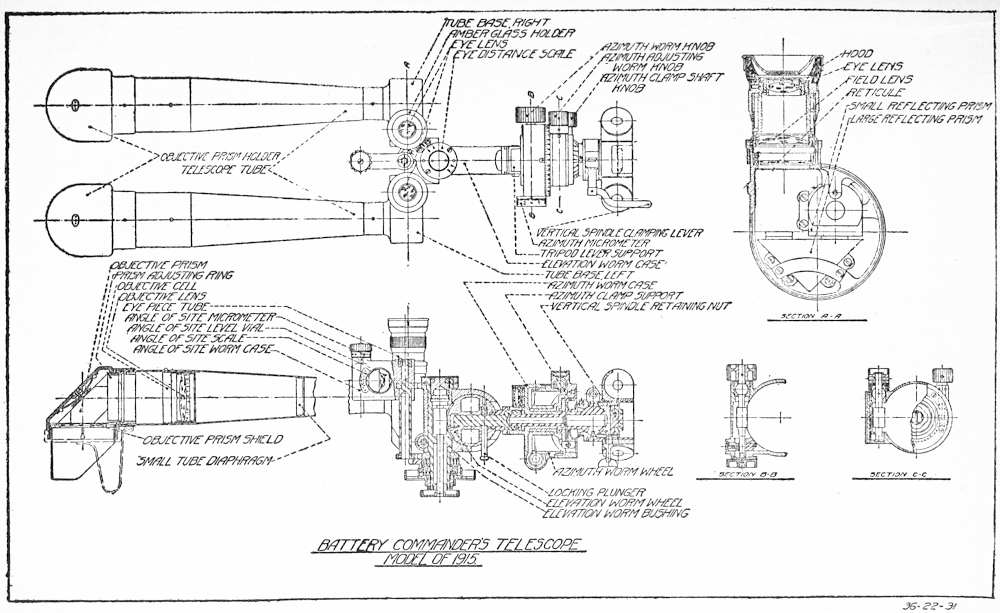

| Battery Commander’s Telescope, Model 1915 | 271 | |

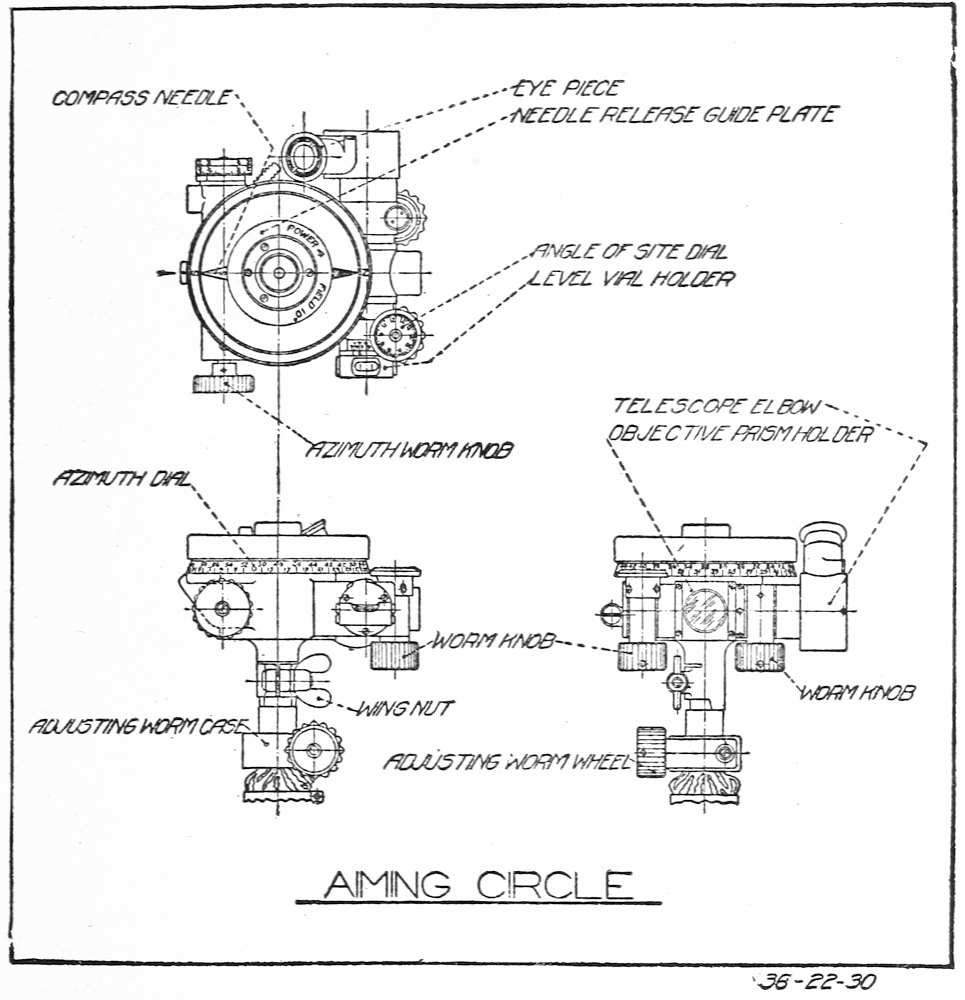

| Aiming Circle | 275 | |

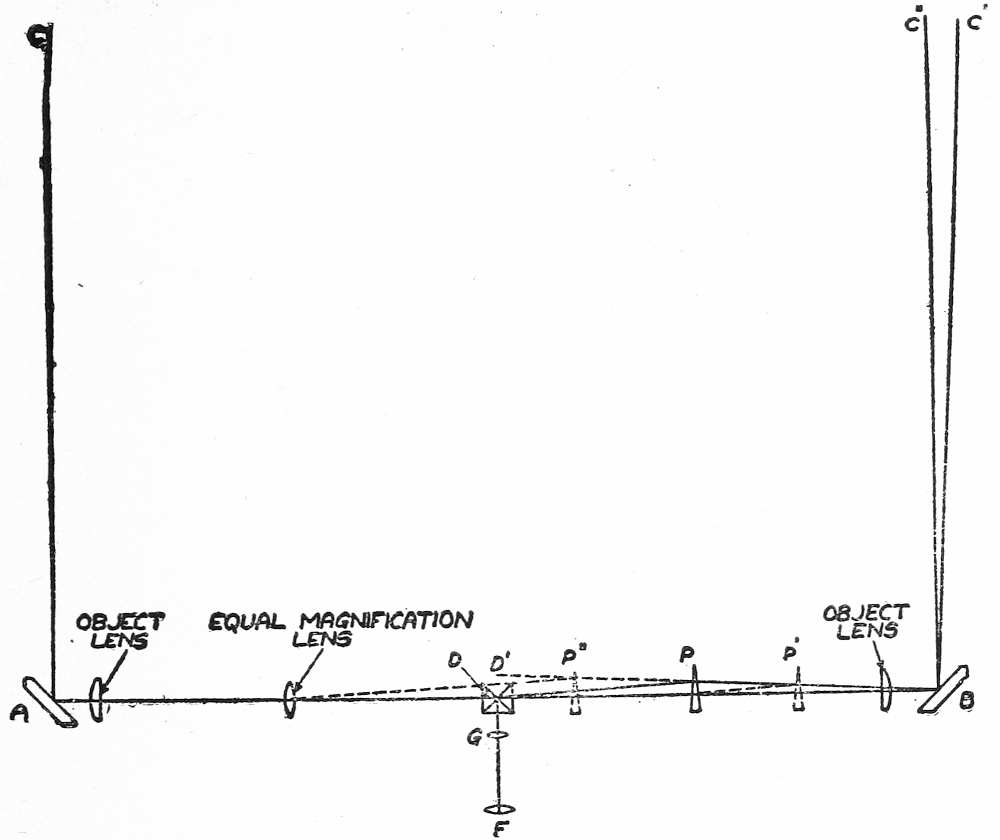

| Diagram of Range Finder Principle | 279 | |

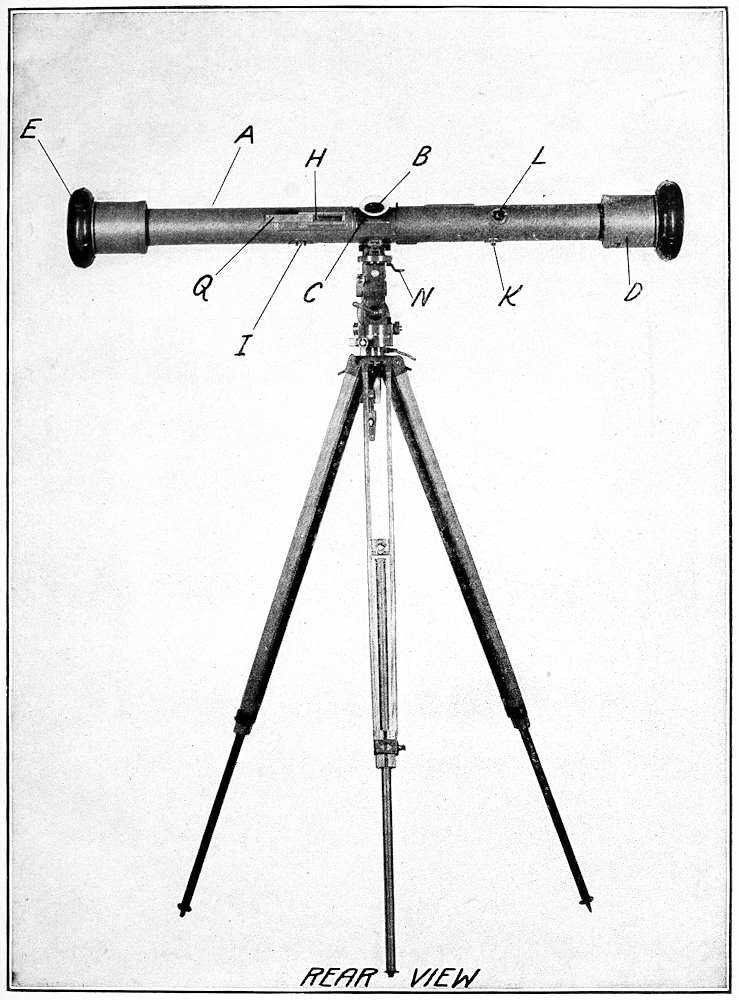

| Range Finder, Rear View | Facing 280 | |

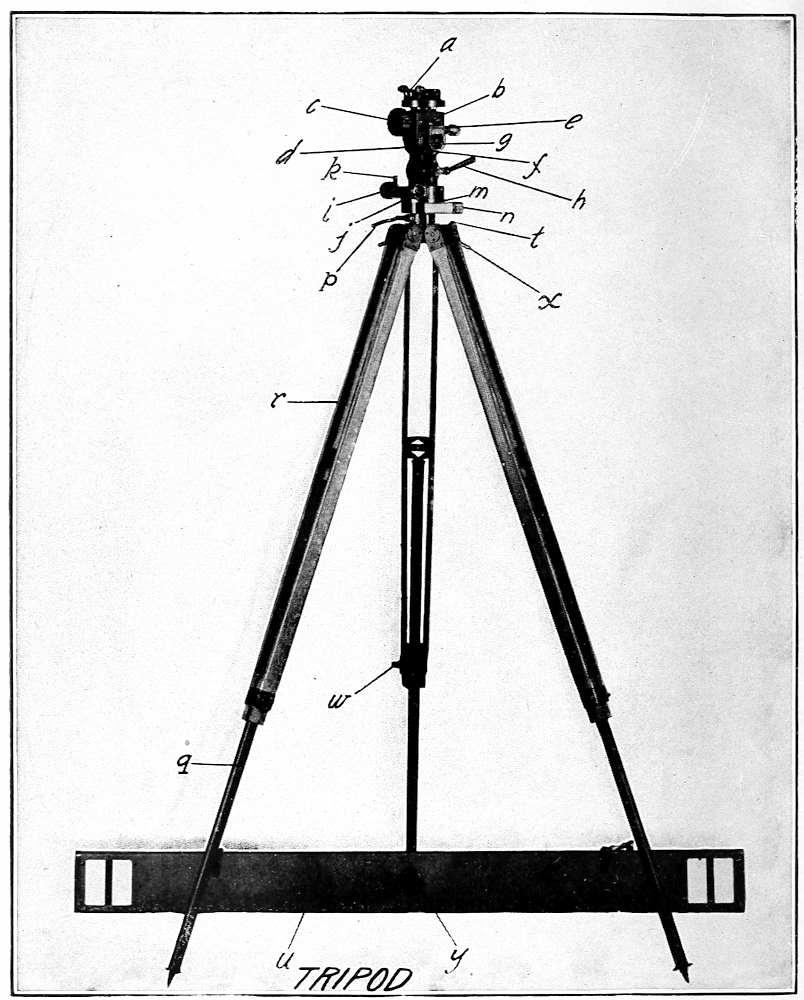

| Range Finder Tripod | Facing 281 | |

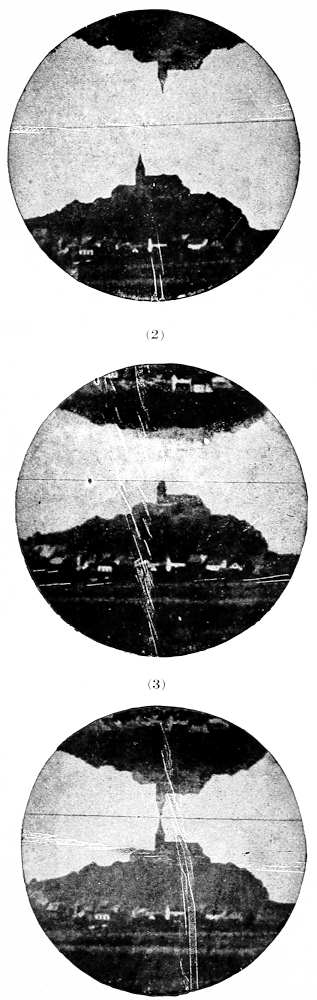

| Three-Steps in Range Finding | Facing 282 | |

| Fuze Setters | Facing 284 | |

| Camp Telephone | Facing 286 | |

| Diagram Telephone Circuit | 287 | |

| Diagram Radio Circuit | 307 | |

| The Automatic Pistol, Cal. 45, Model 1911 | Facing 316 | |

| Receiver, Barrel and Slide | Facing 317 | |

| Component Parts | Facing 318 | |

| Component Parts Assembled | Facing 319 | |

| Ammunition Truck | Facing 334 | |

[Pg 11]

In the study of any subject which is rather technical in nature, it is absolutely essential that the reader be familiar with the meaning of the words and phrases which must be used in the matter to be discussed. If the subject matter is to be understood there must be a common phraseology. The reader is therefore strongly urged to perfect his knowledge of the following short vocabulary before passing on to the matter which follows.

Ammunition. A general term applied to all forms of powders, shells, cartridges, primers, etc.

(a) Fixed Ammunition. When the powder charge is enclosed in a metallic container which is fixed to the projectile, it is called “Fixed Ammunition.”

(b) Semi-Fixed Ammunition. When the charge and metallic container are a fixed unit but are not fastened to the projectile, it is called “Semi-Fixed Ammunition.”

(c) Separate Ammunition. When the powder charge is contained in bags separate from the projectile and containing not a fixed but a varying charge, it is called “Separate Ammunition.”

Artillery. All firearms not carried by hand, excepting machine guns. It is divided into two general classifications: (1) artillery of position, and (2) mobile artillery.

(1) Artillery of Position is that which is permanently mounted in fortifications.

[Pg 12]

(2) Mobile Artillery consists of two classes: first, artillery designed to accompany an army in the field; second, railway artillery which requires tracks for its transportation.

Ballistics. The science of hurling projectiles or of the motion of projectiles in their flight.

Bore. The hole which extends from the muzzle to the breech. The passageway for the projectile. That part of the tube which is bored out.

Breech. The rear end of the gun, tube, or barrel.

Caisson. A two-wheeled vehicle which supports an ammunition chest. The wheeled equipment of a gun section consists of one gun with its limber and one caisson with its limber. For a caisson section it consists of two caissons with their limbers.

Caliber (Calibre). The diameter between the highest points in the bore.

Carriage, gun. Usually understood to mean all the piece except the tube with its appurtenances and the limber.

Cartridge case. A hollow cylinder shaped to fit the bore. A container for the propelling charge.

Charge.

(a) Propelling. A quantity of powder used in the bore to generate the gases which propel the projectile from the gun.

(b) Bursting. A quantity of powder used in shrapnel to strip off the head of the projectile and to force out the balls.

(c) Explosive. The matter used in a shell to detonate it at the end of its flight.

Cradle. In general, that part of the carriage which houses the recoil and counter-recoil mechanisms.

[Pg 13]

Elevating Mechanism. The device used to elevate the gun through a vertical arc in order to give the gun an elevation corresponding to the desired range at which the piece is to be fired.

Fire Control Equipment. Those instruments used to compute firing data, observe and correct the fire, such as B. C. Telescopes, Aiming Circles, Range Finders, etc.

Firing Mechanism. A device located in the breechblock for exploding the primer and thus causing the ignition of the powder charge.

Fuze. That part of the round which is fastened to the point or to the base of the projectile and causes the latter to be detonated or exploded near the time or the place desired.

Fuze Setter. A device used to set time fuzes in such a manner that shrapnel or shell will burst at or near the desired height in air.

Gun. A metallic tube from which projectiles are hurled by gases generated from the ignited powder. In general, all fire arms; but in Field Artillery terms, comparatively long-barreled weapons using relatively high muzzle velocity in contra-distinction to the howitzers and mortars.

Howitzer. A weapon which differs from a gun in that for the same caliber it uses a shorter tube, lower muzzle velocity and generally a more curved trajectory. From two to seven varying strengths of propelling charges may be used in the howitzer. This gives it selective angles of fall, and allows the howitzer to reach targets that are hidden from the flat trajectories of guns.

Initial Velocity. The speed with which the projectile first moves.

[Pg 14]

Limber. A two-wheeled carriage which is sometimes used to carry an ammunition chest and always used to support the weight of the trail of the piece or caisson. It adds the other two wheels to make a four-wheeled vehicle.

Materiel. A term used in the Field Artillery in contra-distinction to Personnel.

Mortar. A weapon using for the same caliber, a barrel much shorter than the corresponding howitzer. Used at short ranges with extreme steep angles of fall to reach highly defiladed targets.

Muzzle. The front end of the bore.

Muzzle Velocity. Speed or velocity of the projectile measured as it leaves the muzzle.

Ogive. The rounded shoulder of the projectile.

Ordnance. Arms, ammunition, and their accessories.

Piece. A fire arm, small or large.

Primer. Device used to insure ignition of the propelling charge.

Projectile. The effect-producing part of the round. The bullet-like form which is thrown toward the target.

Quadrant, gunners. A device for measuring angles of elevation.

Recoil Mechanism. That part of the piece which checks the recoil—or kick—that always occurs when a piece is fired. It generally includes the counter-recoil mechanism which restores the tube “into battery” after it has fired.

Rifle. A gun. A weapon with a comparatively long barrel and high muzzle velocity. Rifles under 6 inches seldom use over two different charges. Term used in contrast to Howitzer or Mortar.

[Pg 15]

Rifling. The lands and grooves in the bore of the piece which imparts to the projectile during its passage through the bore, the rotary motion that increases accuracy and range.

Round. Consists of the primer, cartridge case or powder bags, projectile and fuze. For light Field Artillery the round weighs about 18 lbs and the projectile about 15.

Shell. A projectile which secures its effect by the force of its detonation, the bursting of its walls, and the fragmentation and velocity of the fragments. Also used as a gas carrier.

Shrapnel. A projectile which secures its effect by the expulsion in the air of lead balls with shot-gun like effect.

Trail. That part of the piece which extends from the axle to the rear and transmits the force of recoil to the ground through the trail spade. Usually supports the elevating and traversing mechanisms.

Traversing Mechanism. A device used to give the piece direction by moving it through a horizontal arc.

[Pg 16]

In taking up the study of materiel, the Field Artillery student should know something of the history and development of ordnance and the reasons for the various changes which have taken place from time to time.

The sole use of a gun is to throw a projectile. The earliest projectile was a stone thrown by the hand and arm of man—either in an attack upon an enemy or upon a beast that was being hunted for food. Both of these uses of thrown projectiles persist to this day, and, during all time, from prehistoric days until the present, every man who has had a missile to throw has steadily sought for a longer range and a heavier projectile.

In ancient times the man who could throw the heaviest stone the longest distance was the most powerfully armed. During the Biblical battle between David and Goliath, the arm of David was strengthened and lengthened by a leather sling of a very simple construction. Much practice had given the youthful shepherd muscular strength and direction, and his stronger arm and straighter aim gave him power to overcome his more heavily armed adversary.

Projectile-throwing machines were developed after the fashion of a crossbow mounted upon a small wooden carriage which usually was a hollowed trough open on top and upon which a stone was laid. The thong of the crossbow was drawn by a powerful screw operated by man power, and the crossbow arrangement when released would throw a stone weighing many pounds quite a distance over the walls of a besieged city or from such wall into the camps or ranks of the besiegers.[Pg 17] This again was an attempt by mechanical means to develop and strengthen and lengthen the stroke of the arm and the weight of the projectile. The Bible states that King Usia (809-757 B. C.) placed types of artillery on the walls of Jerusalem. The Romans used it in the Punic Wars. The Alexandrian technicians established scientific rules for the construction of early weapons. Athenaeus reports catapults having a range of 656 meters and that the gigantic siege tower at Rhodes successfully resisted stone projectiles weighing 176 pounds.

References to explosives are to be found in works as old as Moses. Archimedes is said by Plutarch to have “cast huge stones from his machines with a great noise;” Caligua is said by Dion Cassius to have had machines which “imitated thunder and lightning and emitted stones;” and Marcus Graecus in the eighth century gives a receipt of one pound of sulphur, two of willow charcoal and six of saltpetre, for the discharge of what we should call a rocket.

The use of Greek fire was understood as early as the sixth century, but powder was earliest used in China, perhaps a thousand years before Christ, and was introduced to European notice by the Saracens.

From the discovery of gunpowder by the English monk Bacon in 1248, sixty-five years elapsed before a Franciscan monk produced the first gun in Germany, about 1313. The first guns were of a small breech-loading type, supported in front by crossed sticks and anchored by a spike at the breech. Later these guns were fastened to cradles, the latter being mounted on sleighs, and finally, in 1376, the Venetians produced the first wheel mounts, which had become common by 1453, when the Turks took Constantinople.

The ancient carriages were remarkable because of the fact that in general design they embodied the same principals which are included in the field carriages of to-day. One example[Pg 18] from the fifteenth century shows a breech-loading gun mounted in a cradle supported by trunnions on the forward extension of the trail over the axle. The cradle was elevated by a pin-and-arc arrangement, supported on the trail. The axle supported by wheels passes through the trail to the rear of and below the cradle trunnion support and in front of the point of attachment of the elevating arc.

Field guns fell into disuse about 1525 with the introduction of musketry, and remained so until 1631, when Gustavus Adolphus gave artillery its true position on the battlefield.

Swedish artillery reigned supreme in the early part of the seventeenth century. Gustavus introduced marked changes by making the guns and the carriages lighter and handier, and by adapting their movements to those of the other arms and to the requirements of the battlefield. In this, as in all his military efforts, his motto was mobility and rapidity of fire.

In 1624 Gustavus had all his old types of guns recast into newer models and the following year he himself contrived a gun which three men and one horse could maneuvre to good effect. It was an iron three and four pounder with a cartridge weighing less than a pound and consisting of a charge held in a thin wooden case wired to a ball. This was the first artillery cartridge, the original fixed ammunition. The gun was afterwards used in other European armies and known as the “piece Suedoise.” Not only had it the advantage of lesser weight but its cartridge was always ready to fire and it could be fired eight times to the six times of the infantry musket of that day.

In the wars against the Poles, Gustavus employed with profit the so-called leather cannon, a fact which shows how lacking the times were in artillery power. These guns were invented in the early 1620s by a Colonel Wurmbrandt, and[Pg 19] consisted of a thin copper tube reinforced by iron bands and rings, then bound with rope set in cement, the whole covered with sole leather. The tube was made to screw in and out because it grew heated by from eight to twelve charges and had to be cooled. The gun carriage was made of two planks of oak. The gun without the carriage weighed about ninety pounds and was fired with a light charge. They were used during 1628-29 and then gave way for four pounder cast-iron guns which remained in common usage in Europe until artillery was reorganized by Frederick.

Gustavus’ batteries excited universal admiration. Grape and canister were generally employed in the field guns and round shot only in the siege guns. Artillery was used massed or in groups and also with regiments of foot soldiers. Gustavus was probably the first to demonstrate the real capabilities of artillery.

Mortars throwing bombs were first used at the siege of Lamotte in 1634. Hand grenades, shells, fire-balls, etc., came into more general use as the German chemists made their new discoveries. Artillery practice grew to be something of a science; experts took it up and the troops were better instructed. Regimental artillery, that is, artillery with the infantry, was attended by grenadiers detailed for the work. There were special companies for serving the reserve guns.

The period following the Thirty Years’ War—the middle of the seventeenth century—gave no great improvement to the art of war but there were many marked advances in the matter of details of construction. During the era of Gustavus it was Sweden that led in making war more modern; during the era of Louis XIV it was France.

Artillery ceased to be a guild of cannoneers as it long had been and became an inherent part of the army. More intelligence was devoted to it and more money spent on this arm of the service; it grew in strength and importance, and was[Pg 20] markedly improved. But while the artillery service ceased to be a mere trade, it did not put on the dignity of a separate arm, nor was the artillery of any great utility in the field until well along in the eighteenth century. Guns, however, in imitation of the Swedes, were lightened, particularly so in France; powder was gradually compounded on better recipes; gun-metal was improved; paper and linen cartridges were introduced; gun carriages were provided with an aiming wedge; and many new styles of guns and mortars, and ammunition for them were invented.

Science lent its aid to practical men, and not only exhausted chemical ingenuity in preparing powder and metal, but mathematical formulas were made for the artilleryman, and value of ricochet firing was discovered. Louis XIV founded several artillery schools, and initiated the construction of many arsenals. Fontainebleau, the French artillery school which trained many Americans during the World War had its beginning in this period. Finally, the artillery was organized on a battery and a regimental basis, and careful rules were made for the tactics of the guns. These were served by dismounted men and generally hauled by contract horses.

Although sensibly improved, the artillery was far from being skillfully managed and was slow firing; it usually stood in small bodies all along the line of battle. It was heavy and hard to handle and haul, principally because the same guns were used for both siege and field work, and was far from being, even relatively to the other arms, the weapon which it is to-day.

In 1765 General Gribeauval of France introduced artillery improvements, especially in the carriages, and formed a distinct artillery service for the field which was lighter than the old service and was drawn by teams which were harnessed double as they are to-day.

[Pg 21]

Howitzers were introduced in France in 1749. The weapons were given an early sort of perfection by the Dutch. The term “howitzer” comes from the German “haubitz.” In 1808 the first shrapnel appeared at Vimera. It was invented by an English colonel by the name of Shrapnel. At the time it was known as case shot. The type employed by Napoleon, had a fuze that could be used at two different ranges. The French still have this type in their armament.

Field artillery now began to appear in the form which it was to retain with but a few changes, until the era of the modern field carriage. The cradle disappeared, muzzle-loading guns cast with trunnions taking its place, and a stepped wedge resting on the trail superseded the pin and arc. With the exception of the gun, most parts of these carriages were of wood and were to remain so until 1870, when metal carriages came into general use. Muzzle loading guns had supplanted breech-loaders because of the poor obturation and the many accidents resulting from use of the latter type. Although numerous experiments were made, breech-loading guns did not come into vogue again until 1850, when the experiments of Major Cavalli (1845), the Walnendorff gun (1846) and the Armstrong gun (1854), produced satisfactory types.

Up to 1860 practically all guns were smooth bore. Even during the Civil War the smooth bore was generally used, although the rifled gun began to make an appearance and was used in small numbers by both sides at the battle of Gettysburg. Some breech loaders began to appear at the same time. Improvement in the ballistic properties of the gun necessitated a corresponding improvement in the sighting facilities. In 1880 rifled breech loading and built-up steel cannon came into general use. Rifled guns shoot accurately and as a result, improved methods in direct laying were devised.

[Pg 22]

The period between from 1880 to the present, has brought about changes in gun construction which, possibly, have been equaled in importance to artillery only by the present change which is taking place in the means of artillery transportation and self-propelling mounts. In this period in rapid succession came the modern breechblock and with it the rapid firing gun. This brought about the change to the present system of breaking the force of recoil of the gun and restoring it to its firing position without disturbing the position of the carriage. This added to the possibilities of rapid and more accurate fire. Then came the invention and use in the field artillery of smokeless powder. Previous to this time the great amount of smoke produced by the black powder when the piece was fired retarded the rapidity of fire because it enveloped the materiel in a thick cloud of smoke which obscured the target and made it impossible to fire again until the smoke had blown away. It made concealed positions for the artillery almost impossible. The advent of smokeless powder made firing more rapid and made possible the selection of concealed positions. This in turn made indirect fire feasible and necessitated the development of better sights. Indirect fire increased the rapidity of fire and gave to the commanders of firing units a greater control over their fire. With the use of recoil mechanisms and shields for the guns, the cannoneers were permitted to serve the piece continuously—a condition which was impossible with the recoiling carriage. The shields made it almost impossible to put the gun out of action unless some vital part of the mechanism was destroyed.

The first of the modern carriages which were produced in the early nineties should be classified as semi-rapid carriages, as the recoil brakes were so abrupt that the carriage was not stable and jumped considerably, gaining for the type the sobriquet of “grass-hopper guns.”

[Pg 23]

In 1897 the immortal French “75” was born, the pioneer of all modern quick-firing field guns, which still maintains its superiority in many respects over later designs.

In 1902 our own 3-inch field gun was produced and still finds favor among many of our field artillery officers, even over the French “75.”

The Deport carriage brought to this country from Italy, in 1912, introduced to us the split trail, high angle of fire, wide traversing type of field gun carriage. This carriage was extensively tested by the Ordnance Department; by the Field Artillery Board at Fort Riley, Kansas; and by the School of Fire for Field Artillery, at Fort Sill, Oklahoma. The Field Artillery Board unqualifiedly approved of the Deport carriage and recommended that it be adopted. The School of Fire for Field Artillery also approved of this type.

In 1916 the United States produced a 75-mm field gun which featured a split trail with an elevation of 57 degrees which permits its use as an anti-aircraft weapon and a variable length of recoil which prevents the breech from hitting the ground at the extreme elevations. It has a traverse of 800 mils in comparison to the 106 of the French 75 and the 142 and 140 of the British 75 and American three-inch field gun.

The outbreak of the late war saw all modern armies largely equipped with guns resembling the French “75” in a long-run recoil mechanism, weight of projectile and weight of carriage, etc. The fact that the largest number of horses which could best be handled to maneuver the light guns—about 6—could not pull over a long period a gun or caisson with its limber if the weight was more than about 4500 pounds, resulted in the practical standardization of light guns in all armies. So in 1914 we see that time and development had given light gun perfection and mastery of artillery technique to the French while the Germans, probably, possessed the most efficient artillery program. The German types of weapons[Pg 24] were more varied and perhaps better suited to the varying artillery needs in rendering that assistance to the infantry for which the artillery exists.

In our service during the World War, French 75s and the 155-mm Howitzer were used as divisional artillery. Two regiments of the light guns and one regiment of 155-Howitzers were assigned to each infantry division. As the war progressed guns and howitzers ranging from the 4.7” rifle, up to, and including 14 and even 16-inch naval guns on railroad mounts, were used as Corps and Army artillery.

Thus artillery development has gone steadily forward. Every military power has striven with the aid of its best engineers, designers and manufacturers to get a stronger gun, either with or without a heavier projectile, but in every case striving for greater power. As a special development and a not too important one, due to its lack of effectiveness in comparison to its cost, we find the now famous long range gun of the Germans, successfully delivered a projectile approximately 9 inches in diameter into Paris punctually every twenty minutes from a point about 75 miles distant. The Germans used three of these guns in shelling Paris. Their life was probably limited to about 75 rounds due to the excessive demands made upon the materiel.

The American Field Artillery Service now has before it four types of field gun carriages, namely our 3” model of 1902; the French 75 M-1897; the British 18 pounder, M-1905 converted to a 75-mm (known as the model of 1917); and our 75-mm model, 1916. There is being produced (1919-20) an improved model of 1916 75-mm carriage on which the St. Chamond pneumatic recuperator, adopted jointly by the American and French governments, will be substituted for the spring recuperators; and the French 75-mm gun will be substituted for our shorter calibered type. From these types one must be selected. An intelligent selection involves a consideration[Pg 25] of what may be expected in the future in order that it may best fit in with the new types yet to be evolved.

For horsed artillery—and horse artillery will be with us for some years to come—the limiting features of draft and man power will still pertain.

For tractor-drawn mobile artillery, the limiting feature is the tractive power of the tractor with relation to the weight of the gun and carriage, the unit being physically limited in weight by the supporting-power of the pontoon bridge which is about 10,000 pounds per vehicle.

For Caterpillar Artillery.—By that is meant guns mounted on caterpillar tractors—the limiting features are power and weight, coupled with the weight limitations of the pontoon bridge. To circumvent the question of weight, the load may be divided by mounting the motor by an electric generator on one caterpillar and the gun with an electric motor, on the other, a transmission cable connecting the two vehicles.

In conclusion it might be said that one of the greatest changes which has ever taken place in the development of field artillery is now underway in the form of motorization. Prior to 1917 horse traction had been the sole means of transporting mobile field artillery. The limit of the capabilities of horse traction placed a weight limit upon gun construction and to some extent upon artillery tactics. The increase in the ratio of field artillery to infantry, the corresponding demand for artillery types of horses and the decrease in the availability of the latter as the war continued, combined with the great improvements which were constantly being wrought in mechanical transportation as the war lengthened, opened the way for artillery motorization.

The French began by placing their 75s on trucks for rapid changes of position. All the armies saw the possible advantages to be gained from the use of trucks with artillery[Pg 26] but none planned—nor have any since put into practice—the extensive use of trucks, caterpillar tractors and motor transportation for personnel, which the United States planned on her entrance into the war. It was planned to equip about one-third of the A. E. F. artillery regiments with complete motor equipment. This plan did not entirely materialize but after the armistice the 3rd Field Artillery Brigade of the 3rd Division was completely motorized and its practice marches in Germany were most successful and full of promise for the future. To date the motorization of all our mobile Field Artillery, with the exception of about fifty per cent of the light field guns, has been authorized.

Motor traction gives a better performance than animal. While the latter, especially with the light field guns, possesses great mobility, it is not a sustained nor a persistent mobility; it is more easily exhausted and requires longer to recuperate. These are points of vital importance from a military viewpoint.

In 1920 a self-propelling caterpillar mounted with a 75-mm gun, model 1916, was tested with a view to ascertaining the ability of the motor to function in water, i. e. fording streams, etc. The caterpillar successfully moved through ice water which completely submerged the carburetor.

Passenger cars for the transportation of personnel, four wheel drive trucks with caterpillar tractors for the transportation of the materiel, and the development of self-propelling mounts for the 75 and 155 rifles are the latest and the most important developments in field artillery materiel.

[Pg 27]

“A gun is a machine by which the force of expanding gas is utilized for the purpose of propelling a projectile in a definite direction.” It is essentially a metal tube closed at one end, of sufficient strength to resist the pressure of the gases caused by the combustion of the powder charge in the confined space at the closed end of the tube behind the projectile. The rapid combustion of the powder, which produces a high temperature, gives rise to a pressure uniformly exerted in all directions within the confined space. The energy exerted is used in forcing the projectile from the tube.

Due to the effort of the large amount of superheated gas generated, which tends to expand in all directions, tremendous rending stresses are set up in the tube. Formerly these stresses were met by a sheer mass of metal, but, as the size of the projectiles increased and the necessary pressure to give them muzzle velocity increased, the size of the guns increased beyond the practical limits of mobility. This was at first offset by forgings of refined alloyed steels, but even these failed to keep pace with the increasing pressure desired. The new condition was met by the introduction of the “built-up” and the “wire-wrapped” guns. The modern built-up gun is made by assembling one or more superimposed cylinders around a central tube. The superimposed cylinders, whose inside dimensions are slightly smaller than the outside dimensions of those on which they are to be assembled, are expanded by heat sufficiently to allow them to be assembled over the[Pg 28] tube. The subsequent contraction on cooling causes each of them to exert a uniform pressure on the cylinder immediately underneath. This method of assembling is called “shrinkage.” This gives a compression to the inner tube and a slight tension to the outer one. The compression is so much additional strength to the tube because it must first be overcome before the powder gases can exert a tension on the inner tube fibers. The exact amount of the compression and tension for all parts of a gun at rest or resisting an explosion is a matter of mathematical calculation. The built-up construction has been used in practically all our present day types of field artillery.

Wire-wrapped guns consist of:

(a) An inner steel tube which forms a support on which the wire is wrapped and in which the rifling grooves are cut.

(b) Layers of wire wrapped upon the tube to increase its resistance by the application of an exterior pressure as well as to add to the strength of the structure by their own resistance to extension under fire.

(c) One or more layers consisting of a steel jacket and hoops placed over the wire with or without shrinkage. The jacket generally furnishes longitudinal strength to the guns, and the breech block is screwed into the jacket, or into a breech bushing, which is screwed into the jacket.

The principal advantages of this type of gun over the built-up is economy of manufacture and greater facilities for inspection of materiel in the layers over the tube. The wire wrapping has itself a large reserve of strength due to the high elastic limits that may be given it. Two methods are used to wrap the wire: (a) at constant tension (b) at varying tension so that when the gun is fired with the prescribed pressure,[Pg 29] all layers of wire shall be subjected to the same tangential stress. The latter method is theoretically better, but because of the ease of manufacture, together with the large factor of safety possible, the wire is usually wrapped at a constant pressure.

All army guns except small howitzers or mortars are of the built-up or wire-wrapped type. Built up guns of less than 5” caliber, or howitzers up to 8” caliber consist of an inner tube and a jacket shrunk onto this tube. The jacket covers the breech end of the gun and extends forward to the center of gravity. Built-up guns of larger caliber have one more layer of hoops in addition to the jacket, one layer of hoops usually extending to the muzzle.

The bore of the tube forms the powder chamber, the seat for the projectile and the rifled bore. Rifling consists of a number of helical grooves cut in the surface of the bore. The soft metal of the rotating band of the projectile is forced into these grooves causing the projectile to take up a rotary motion as it passes through the bore. This is necessary in order to keep the projectile stable in its flight.

By twist of rifling is meant the inclination of one of the grooves to the element of the bore at any point. Rifling is of two kinds: (a) Uniform twist, or that in which the twist is constant throughout the bore, (b) Increasing twist or that in which the twist increases from the breech towards the muzzle.

The twist of rifling is usually expressed in the number of calibers length of bore in which it makes one complete turn. The twist actually required at the muzzle to maintain the[Pg 30] stability of the projectile varies with the kind of projectile and the muzzle velocity. If a uniform twist be used, the driving force on the rotating band will be at a maximum when the pressure in the guns is at a maximum—or near the origin of rifling (seat of the projectile). The increasing twist serves to reduce the maximum driving force on the band thus lessening the danger of stripping the band. This is its principal advantage over the uniform twist, though it also reduces slightly the maximum pressure in the gun. The principal disadvantage of the increasing twist is the continued change in form of the grooves pressed in the rotating band, as the projectile passes through the bore. This results in increased friction and a higher value for the passive resistance than with a uniform twist. (Note: greater ranges obtained by cutting grooves in projectile, principal used on the long range gun by the Germans.) If the twist increases from zero at the breech uniformly to the muzzle, the rate of change in the tangent to the groove is constant. A twist in this form offers less resistance than the uniform twist to the initial rotation of the projectile. To still further diminish this resistance a twist that is at first less rapid than the uniformly increasing twist and later more rapid has been generally adopted for rifled guns.

Formerly in our service the twist was uniform; one turn in 25 calibres for guns and one turn in 20 calibres for howitzers. All the latest model army guns, however, have an increasing twist of one turn in 50 calibres at the breech to one turn in 25 calibres at a point from 2 to 4 calibres from the muzzle. In howitzers and mortars the twist is sometimes one turn in 40 calibres at the breech to one turn in 20 calibres at a point several calibres from the muzzle. Some mortars are rifled with a uniform twist and some guns have a rifling which begins with a zero twist. (The 1905 3” gun, 0 to 1 in 25.)

[Pg 31]

Outside of the tube is the jacket. It extends to the rear of the tube a sufficient distance to allow of seating the breech block. In this manner the longitudinal stress due to the pressure of the powder gases on the face of the breech block is transmitted to the jacket thus relieving the metal of the tube from this stress. In all built-up guns there is some method devised for locking the tube to the jacket so as to prevent relative movement of these parts.

Considering the gun alone the greatest range is obtained at an angle of about 43 degrees from that gun which fires the heaviest projectile with the greatest velocity. The caliber being limited to from 2.95 inch to 3.3 inch, the projectile is limited in weight to from 12 to 18 pounds. The weight of the gun is limited to between 700 and 1000 pounds and in length to between 27 and 36 calibers. The longer the gun, the greater the weight and velocity from the same charge of powder. A pressure of 33,000 pounds per square inch with a corresponding velocity of 1700 f. s. has been found to be as high a pressure and velocity as are desirable for a reasonable length of life for a field gun, the average life of which is 10,000 accurate rounds.

Under the French school of artillery, which dominates our service at present, our bore is 75-mm, the weight of our shell 12 pounds, our shrapnel 16 pounds, the velocity for the one about 1,750 f. s. and for the other about 1,680 f. s.

The breechblock appears in four distinct types. Our own service has for years used the swinging interrupted screw breechblock which in the 1905 model is the equal of any of that type in existence. The swinging block has serious disadvantages for high angle fire in that it requires an excessive[Pg 32] amount of room to operate and is difficult to load at high elevations.

The Italians have introduced a new breechblock in one of their recent guns, consisting of a half cylinder with superimposed spherical face on its cylindrical surface rotating vertically about a horizontal axis perpendicular to the axis of the bore. The gun is loaded through a groove in the breechblock when the latter is in its horizontal position. The block, which is semi-automatic, is very satisfactory. It is adapted to high angle fire.

The French in their “75” have used the rotating eccentric screw type, which is rapid in movement and lends itself fairly well to high angle fire. It is completely enclosed and of rugged construction.

The Germans have used the sliding wedge type of block, moving in a horizontal direction, which does not lend itself to high angle fire.

The United States in its recent field carriage adopted the sliding wedge type in a vertical plane on account of its manifest superiority in fire at high angles. This block is rather difficult to manufacture and the type has a tendency to stick. The automatic closing necessitates a strong closing spring which fatigues the block operator, No. 1 in the gun squad. It is interesting to note that in a prospective new design for the 1916 gun carriage the American Ordnance Department adopted the French breechblock; and the St. Chamond Company, designing for the American Expeditionary Forces, adopted the American drop block.

Requirements for a breech mechanism:

The following may be said to be the principal requirements for a successful breech mechanism.

1. Safety. To be safe: (a) the gas must be restrained from escaping to the rear; this sealing or obturation must be automatic, greater pressure insuring better obturation. (b)[Pg 33] The breech of the gun must not be weakened by the fitting of the breech mechanism. (c) The parts must have ample strength to prevent any portion from being blown to the rear. (d) The danger of premature discharge must be minimized. (e) The breechblock must be securely locked to prevent opening on firing.

2. Ease and Rapidity of Working. Otherwise, rapid and continuous fire cannot be maintained. Hence this would include facility in loading and certainty of extraction for rapid fire guns.

3. Not Easily Put Out of Order. In other words it must be able to meet service conditions and hard usage. Parts should have a reserve strength.

4. Ease of Repair. Parts most exposed to wear should be so designed as to permit being replaced. This will also include accessibility to parts, so that breakage of a part will not disable the mechanism for a long time.

5. Interchangeability. Not only should individual parts be made interchangeable by accurate workmanship, but the whole mechanism should be capable of being mounted on similar guns. This is to meet service conditions.

A modern gun carriage is expected to stand steady on firing, so that in the first place it requires no running up, and in the second place it maintains the direction of the gun so that only a slight correction in elevation and direction is required after each round. The carriage is maintained in position by the spade, which sinks into the ground, and by the friction of the wheels upon the ground. If the force of the recoiling gun were communicated directly to the anchored carriage the effect would be to make it jump violently, which would not only disturb the lay, but would prevent the cannoneers from maintaining their position. The hydraulic recoil[Pg 34] brake is therefore interposed between gun and carriage. If the guns were rigidly attached to the carriage the latter would be forced back a short distance at each round, and the whole of the recoil energy would have to be absorbed in that short motion. Instead of this the gun alone is allowed to recoil several feet and although the recoil energy is in this case greater than it would be if gun and carriage recoiled together yet it is so gradually communicated to the carriage that instead of a violent jerk we have a steady, uniform pull, the only effect of which is to slightly compress the earth behind the spade. In a well designed carriage the amount of this pull is always less than that required to lift the wheels off the ground by rotating the carriage about the spade.

The only motion of the carriage which takes place is that due to the elastic bending and rebound of its parts under the cross strains set up on discharge. These strains are inevitable since the direction of recoil cannot be always exactly in the line of the resistance of the earth behind the spade. This movement of the axis is known as jump and must be determined by experiment for the individual piece in its particular mounting.

The principal parts of the typical gun carriage are the cradle, a device for mounting the cradle—called in the different models rocker, pintle yoke, and top carriage, the trail, the wheels and axle. The gun slides in recoil on the upper surface of the cradle and the cradle contains the recoil controlling parts.

In the design of the carriage the constructional difficulty lies not so much in preventing the carriage from recoiling but in preventing the wheels from rising off the ground on the shock of discharge. The force of the recoil of the gun, acting in the line of motion of the center of gravity of the recoiling parts, tends to turn the carriage over backwards about the point of the trail or center of the spade. This force is resisted[Pg 35] by the weight of the gun and carriage, which tends to keep the wheels on the ground. The leverage with which the overturning force acts is due to the distance of its line of action above the center of the spade; the leverage with which the overturning force acts is that due to the horizontal distance of the center of gravity of the gun and carriage from the center of the spade.

It follows that the steadiness of the carriage for a given muzzle energy may be promoted by four factors.

(a) Increasing the weight of the gun and recoiling parts. This reduces the recoil energy.

(b) Increasing the length of recoil allowed. This reduces the overturning pull.

(c) Keeping this gun as low as possible either by reducing the height of the wheels, or by cranking the axle downwards. This reduces the leverage of the overturning force.

(d) Increasing the length of the trail. This increases the leverage of the steadying force.

The well designed gun carriage is one that combines these factors in a practical way so as to give the greatest possible steadiness to the carriage at the same time keeping within the limits of weight imposed by the necessity of mobility.

Gun carriages are constructed so as to permit movement of the tube in the vertical and generally in the horizontal plane. These two motions may be made simultaneous if so desired by proper combination of the two motions and the axis of a gun aligned in any desired direction within the limits of motion of its mount. The two motions referred to are designated as follows: (a) Rotation of the piece about a vertical axis, its inclination with the horizontal remaining unchanged is called “traverse.” (b) Movement of the piece in a vertical plane, the direction of the horizontal projection of the axis of the bore remaining unchanged is called “elevation.”

[Pg 36]

In order to permit of the two motions mentioned, gun carriages are provided with mechanisms for giving the piece accurately controlled motion in both elevation and traverse. The elevating gear of most American guns is an application of the Chinese or Telescopic screw. This gives a short assembled length with the necessary extended length required for modern ranges. It also gives the necessary rapidity for action. An entirely different mechanism is used in our howitzers and American 75s. In this case motion is communicated to the rockers, which carry the gun and cradle, through the engagement of worms with teeth cut on the lower circular edge of the rockers, the latter being pivoted on the cradle trunnions.

Movement of the gun in traverse is accomplished in two general ways.

(a) Pivot on the gun carriage axle.

1. The gun and cradle move around a vertical pintle or pivot placed in a saddle or rocker which itself pivots on horizontal trunnions or bearings usually attached to the axle. The rear end of the rocker forms a seat or bearing on which the cradle and gun move in traverse. The upper end of the elevating screw is also attached to the rear end of the rocker. This allows the rocker and cradle to be moved together in elevation and the cradle to move on the rocker in traverse.

2. The gun and cradle are mounted by means of horizontal cradle trunnions on a top carriage. The top carriage moves in traverse around a vertical pintle or bearing attached over the axle and between the front end of the trail flasks. The rear end of the top carriage moves on bearings attached to the top of each side of the trail flasks. This allows the gun, cradle and rocker to move in elevation with respect to the top carriage and the top carriage bearing the gun, cradle rocker[Pg 37] and elevating mechanism to move in traverse with respect to the bottom carriage.

(b) The gun, cradle and trail move in traverse by sliding along the axle of the carriage on bearings provided for that purpose. In this case the trail spade is the point of pivot.

The first system is the one generally used on all American gun carriages except the 155-mm Howitzer. It gives ease and speed in the manipulation of the piece in traverse, but has the disadvantage of rendering the carriage less stable in firing due to the fact that the direction of recoil of the gun is in the direction of the line joining the trail spade and the central pivot, only when the gun is absolutely in the center of its traverse. In all other positions, which will be the usual case, there is a component at right angles to the line of trail spade-central pivot which tends to throw the gun off from its proper direction making it necessary to relay each time the gun is fired. The second method is that in use on the French 75-mm gun and the French and American 155 howitzer. While not so easy of manipulation and giving less freedom of movement in traverse (about 106 mils) it still has the advantage in that it gives greater stability in firing due to the fact that the gun always recoils along the line through the trail spade, perpendicular to the axle.

There are two general classifications of gun carriages according to the manner in which the laying for elevation is effected. The 3” gun is an example of one type in which the total quadrant angle of departure is laid off as one angle necessitating at each resetting of a range a new resetting of the range bubble. It is evident that this militates against both speed and accuracy in laying for elevation. The other type is illustrated by the American 75 and by the French and British 75-mm gun carriages which have what is called the “independent line of site.” It differs from the other type in[Pg 38] that there is placed between the top carriage and the cradle an intermediate carriage or rocker arm pivoting on the gun trunnions at one end, and carrying at the other the support for the elevating device which gives to the cradle and the gun the proper elevation for the range. This intermediate carriage or rocker arm has a toothed edge geared with a pinion fastened to the trail flask, by means of which, gun cradle and elevating device may be moved in elevation without disturbing the relation between itself and the gun, this being done by gears independent of the elevating mechanism. An angle of site may be set off for the intermediate carriage and after the bubble is centered this actuating pinion may be blocked and no further concern be paid to the angle of site. A cannoneer therefore has only to set his range accurately on the index to give the changes in range ordered.

Elevation is accomplished by telescoping screws, by circular racks and pinions, and by worms and arcs. Telescoping screws are good for from 15 to 20 degrees in elevation only, as for greater angles they become rather too large and cumbersome. The elevating arc is attached on the top, on the bottom or on the side of the cradle and, if possible, at its center. When the latter is not possible, two arcs are generally used to prevent torsional strains developing. Top racks are exposed to fire, side circular racks or arcs interfere with the traverse, with the placing of the sights, and with the general handling of the carriage. The bottom of the cradle is perhaps the best location for the rack. As in the traversing mechanism, a train of bevelled gears transmits the power from the hand wheel to the elevating mechanism.

In both the traversing and elevating mechanism, strength, simplicity, power, accessibility, non-interference and absence of lost motion are the features sought. To secure these is one of the most difficult things in gun-carriage design; for, since the traversing and elevating are the last two elements[Pg 39] considered, they must, therefore, be the ground for modification and the means of adapting the great main elements—namely, wheels, axle, trail, recoil mechanism and gun—into a unit.

The recoil system of the gun carriage consists of a recoil brake, a counter recoil mechanism and a counter recoil brake. The function of each part is apparent from its name. Various systems of checking recoil on field guns have been used, among them may be mentioned; friction devices including brakes on the wheel, inclined planes, pneumatic and hydraulic brakes. All have either been superseded by the last named or are used in connection with hydraulic brakes. The power of the brake lies in the pressure produced in the cylinder through the resistance to motion offered by the liquid flowing through apertures. By varying the size of these apertures the braking effect may be controlled so as to fulfill the conditions demanded by the service. In designing the brake, the effect of the counter recoil system, angle of fire, length of recoil, friction and pressure within the cylinder must all be considered. In howitzers which are designed to be fired at high angles of elevation, the recoil must be shortened to prevent the breech striking the ground, a condition successfully met. Since the pressure due to recoil is ultimately led into the ground through the trail and spade, consideration must be given to the problem of the moment of inertia about the trailspade. The tendency to turn over backward about the spade as the center is offset by the amount of the weight of the carriage with respect to the same point. This raises the question as to how much pressure may be allowed to act to the rear; all of which must be considered in designing the carriage. The counter recoil systems in general use are two: spring or pneumatic. The former is illustrated in our 3” and 75-mm[Pg 40] field guns, the latter by the French 75-mm gun and 155-mm howitzer. Their purpose, of course, is to return the gun “into battery” after it has recoiled on the carriage.

The recoil mechanism is a study in itself, of which there are two schools—the advocates of the spring and of the air recuperators. Great Britain, Germany and the United States have been the advocates of spring recuperation and France of air recuperation. Great Britain and the United States were of the spring school, undoubtedly, because of the lack of a satisfactory air recuperating system; which is rather strikingly proven by the fact that both countries have adopted air recuperation since they have procured or developed satisfactory types.

Both schools have grounds for their position, however. The spring school has in its favor simplicity of design and manufacture and ease of replacement, which can be done in the field. On the other hand, spring recoils have many breakages and greater weight combined with a high replacement of weakened springs, the life varying from 3000 to 8000 rounds.

The air school has in its favor a high order of efficiency—smoother action, general all around efficiency and less weight. But the air recuperator is difficult to manufacture, costly, and when damaged must go to the rear to be repaired; which, however, it seldom needs.

In mounting the spring recuperator, the most recent practice has separated the recoil mechanism from the springs in order to distribute the piston rod pull, thus preventing whip and allowing easy access to the various parts for replacement, refilling and repairs. In order to lower the center of gravity, the gun is slung under the recoil cylinder with the two spring recuperators below and on either side.

Air recuperators are invariably located below the gun for protection and because of their large size and shape, which adapt them for attaching the elevating mechanism.

[Pg 41]

BATTERY OR FIRING POSITION

IN-BATTERY OR FIRING POSITION

HYDRO-SPRING RECOIL SYSTEM

HYDRO-PNEUMATIC RECOIL SYSTEM WITH FLUID IN DIRECT CONTACT WITH THE AIR

[Pg 42]

In either system, the recoil is taken up by means of oil or glycerine and water passing through an orifice created by a slotted piston passing over ribs of varying height, or through a valve on the pressure side of the piston, or by a solid or perforated piston passing through a perforated intermediate cylinder.

The latter type is particularly adapted to variable recoil guns as the intermediate cylinder can be rotated, thus throwing varying orifices into position for the flow of oil.

Counter recoil is accomplished by the springs or by the air pressure in the hydro-pneumatic system, in which the air pressure is sufficient to hold the gun in battery at all elevations and is built up at recoil.

In all counter recoil systems, it is necessary to insert a buffer to take up the remaining energy of the springs or air pressure so as to bring the gun into battery without appreciable jar. Numerous types have been developed and perfected.

The counter recoil brake or buffer in our 3”-gun is a slightly tapered bronze rod, tightly fitting in the cylindrical bore of the piston rod. The retardation caused by forcing the oil in the piston rod out through the small clearance between the buffer and bore of the piston rod eases the return to battery without jar to the gun, which has been forced back by the counter recoil springs.

The physical law that action and reaction are equal has a peculiar emphasis when applied to the firing of a piece of high powered artillery. The force exerted to throw a heavy projectile 7 miles or more from the muzzle of the gun is toward the breech of the weapon in its recoil. How some of these forces are handled safely and easily by mechanical means are almost beyond the mind’s grasp. Not long ago a touring car, weighing two tons, traveled at the rate of 210 miles an hour along a Florida beach. Conceive of such a car going 337 miles an hour—which is much faster than any man ever[Pg 43] traveled; then conceive of a mechanism which would stop this car, going nearly six miles a minute, stop it in 45 inches of space and one-half a second of time without the slightest damage to the car. This is precisely the equivalent of the feat performed by the recuperator of a heavy howitzer after a shot.

Although cover for the cannoneers had been used off and on since the invention of guns, it had fallen into disuse until it was firmly established as an essential feature by the French on their 75-mm in 1897. All modern field guns have such protection both for the cannoneers and for the delicate parts of the material which would be damaged by shrapnel balls or shell fragments. The shield is made of hardened steel capable of withstanding the impact of a bullet of a service rifle at a 100 yds. range at a standard velocity. For convenience the shield is divided into three parts known as the top shield, main shield and apron, with suitable ports equipped with shutters for the line of vision from sights. The main is fastened to the axle and is rigid. The apron is hinged to the main shield or the axle-swinging forward for the traveling position. The top shield is fastened to the main shield by hinges and swings forward and downward for traveling position.

The sights serve three important functions. They improve the vision of the gunner and lay the gun in elevation and direction. The simplest sight is the one over the line of metal which lays for direction only, the second is the tangent sight mounted on a range arc centered on the axis of rotation in elevation usually having a deflection scale to correct for drift and to lead the moving target. This unit lays for range and direction. The last sight is the telescopic or panoramic[Pg 44] sight which is mounted on a range arc and lays for direction only, it is the unit for indirect fire, laying for direction, and markedly improving the vision of the gunner. The latest model of the American panoramic sight is superior to any in existence.

For precision in indirect fire, practically all carriages are equipped with some form of range quadrant, containing a means of setting off the angle of site and the range angle. All instruments are equipped to compensate for difference in wheel level. The British carriage automatically corrects for deviation, simplifying the firing date by that element.

The height of the wheels affects the draft, weight, clearance, and stability of the carriage both as to road stability—i. e., low center of gravity; and firing stability—i. e., the overturning movement about the end of the trail. It is now believed that entirely too much stress has been laid on road clearance. Reducing the height of wheel reduces the weight and road clearance, lowers the center of gravity and increases the firing stability; but it also reduces the angle of gun elevation unless the trail is shortened. Firing stability in general is increased by adding to the weight of the gun, lengthening the recoil, slinging the gun as low as possible and lengthening the trail. The less the height of the wheel exceeds four feet the better, despite the poor draft feature, which is compensated for to some extent by a reduction in weight and turning radius.

Axles are straight or of the offset type. The straight axle is stronger for its weight. The drop axle allows the center of gravity to be lowered.

[Pg 45]

Most modern trails are of the sectional built-up type. Some, however, are of tubular and telescopic. The most variable portion of the trail is the spade. It consists of two parts, the spade proper and the float. The former prevents recoil, the latter the burying of the trail. The spades proper are of three types: the fixed, as in the French 75-mm; semi-fixed, as in the 155-mm howitzer; and driven, as in the Deport and American 1916 75-mm. Each has advantages and disadvantages. The driven spade is considered essential for the split trail carriage, as the latter has no means of seating itself; and should one spade take, and not the other the carriage might be damaged when the gun is fired at an extreme traverse.

Split trails introduced a novelty in field gun carriages, in that a compensating device became necessary to adjust for the difference in ground level of the two spades.

Guns are designed to function in a certain way. They are not temperamental. They follow absolutely and certainly fixed mechanical laws. If they fail there is a reason and it can be remedied. Certain parts are given certain shapes and forms, are machined to nice adjustments, and in taking down and assembling them, brains and dexterity are the tools to use rather than force and sledge-hammers. Learn from your text when and how to apply force and above all when not to use it. Treat these guns as you would a friend on whom you know you can depend. They will not fail you.

[Pg 46]

The artillery assigned to a field army should be of such mobility, power, variety and number as to insure the success of its purpose and to enable this success to be gained with the minimum of casualties. The latter point must receive careful consideration in studies of organization, for without adequate artillery preparation and support the successes of the most gallant infantry can in a series of actions become little more than pyrrhic victories. Many actions of our divisions in France resulted in casualties whose numbers decreased in proportion to the number of guns with which divisions were supported. The proportion of guns to the thousand gross strength of infantry, cavalry, and machine guns adopted by the armies of the first class powers before the opening of the present European War in 1914 was:

British, 6.8; French, 4.6; German, 6.4; American 3.2 (Greble Board).

During the war this proportion was constantly increased until at the close under conditions of position or entrenched warfare it was between 8 and 12 per thousand; this varied of course with the activity in different sectors. In quiet sectors and under conditions of maneuver, or open warfare, which necessitated leaving much artillery behind, it was about 6 per thousand.

A program of types of artillery weapons should be founded on the object and the means—that is, the destruction of the target and the projectile to accomplish this. In the study of an artillery program there are two methods of approaching[Pg 47] the subject. First, by starting with a minimum weight of projectile and working up to a reasonable maximum, according to some law and taking the corresponding calibers, a theoretical series of guns and howitzers can be expressed. For instance, if the law be doubling the weight of the projectile the series of types could be:

| Projectile of | 13 | pounds, caliber | 3”. |

| Projectile of | 26 | pounds, caliber | 4”. |

| Projectile of | 52 | pounds, caliber | 5”. |

| Projectile of | 104 | pounds, caliber | 6”. |

| Projectile of | 208 | pounds, caliber | 8”. |

| Projectile of | 416 | pounds, caliber | 10”. |

| Projectile of | 832 | pounds, caliber | 12”. |

| Projectile of | 1664 | pounds, caliber | 14”. |

The second and more logical method, and one followed in our service, is to consider the artillery missions and determine the types best suited irrespective of any theoretical series of weights and calibers. However, in the discussion of artillery missions and the proper types for their fulfillment there is a remarkable degree of unanimity of thought on these subjects; and the above table actually contains, with slight variations, the types that are most strongly recommended. While granting the great variety of artillery missions that often shade into each other, it is believed that they can best be considered in three great classes that follow the tactical composition of a field army: those of division, corps and army artillery.

Missions. The division artillery, first of all, must have the mobility that will permit it to accompany the infantry of a division and the maximum power consistent with that mobility; its object must be primarily the infantry of the opposing division. It is therefore bound to its own infantry[Pg 48] with the closest bonds and its tactical use cannot be separated from that of the infantry. The division artillery must fire, accurately, a man killing projectile and be prepared for quick changes of targets; it must have a great range because of depth, both of its own and the enemy division; it must continually harass the enemy, prevent his movement and force him into cover or protected trenches. On the defensive it must break up the opposing infantry formations by preparing a counter-offensive fire and by annihilating fire on points from which the enemy attacks emerge; and, failing in these, be prepared to use the barrage and shrapnel fire at close range. In the offensive the division artillery must play its part in the complex schemes of artillery preparation by cutting wire, destroying machine gun nests, gassing areas, concentrating on infantry positions and taking the principal part in the deep barrage that should precede the infantry attack. Its fire, accompanying the infantry movement, requires its own movement and by its mobility it often becomes for some time the sole artillery protection in the preparation and holding of a position which has been taken.

Light Gun and Howitzer. The consensus of opinion of artillery officers is that the division artillery missions are best fulfilled by a light field gun and a light field howitzer having a range of at least 11,000 yards. While differing in mechanical features, the field guns of the different European countries are practically of the same type and, though constant effort is being made to improve details, they can be stated as generally satisfactory to their own governments and not liable to any radical changes. The general type of field gun, while capable of fulfilling most of the division artillery missions, must be supplemented by a proper howitzer. There are many instances where the terrain or the lay of the land offers such protection to the infantry that the field gun cannot bring an effective fire. The howitzer has the great advantage[Pg 49] that with the proper set of propelling charges and, therefore, choice of trajectories for the same range, protected positions can be chosen for howitzers that guns could not use, and angles of fall obtained on objectives that the normal ammunition of guns would not give. The low muzzle velocity of howitzers admits of their almost continuous use in harassing fire and allows the use of a projectile double the weight of that of a field gun. Such a howitzer renders excellent service in wire cutting and is a useful projector of gas shells. To insure the mobility required of all divisional artillery the weight of the howitzer and carriage should not exceed that of the field gun, or about 4,500 pounds.